carbide turning inserts

Carbide turning inserts are precision cutting tools made from cemented carbide, a durable composite of tungsten carbide and a metallic binder like cobalt. Known for their hardness, wear resistance, and ability to withstand high temperatures, carbide turning inserts are essential in metalworking for achieving precise cuts at high speeds.

These inserts are widely used in industries like automotive, aerospace, and manufacturing for turning, milling, and boring operations. They effectively machine materials such as steel, stainless steel, and titanium, handling both roughing and finishing tasks. Carbide turning inserts come in various shapes and coatings to suit specific materials and cutting conditions.

To use, secure the insert onto a tool holder in a lathe or CNC machine, set appropriate speed and feed rates, and cut the rotating workpiece. Their indexable design allows multiple cutting edges to be used, making carbide turning inserts cost-effective and versatile for achieving high precision and smooth finishes.

Why Choose Us

As a leading turning insert manufacturer and turning insert factory, we offer distinct benefits for your machining operations.

Upgrade your sourcing strategy. Contact our turning insert factory today and experience the benefits of working directly with a trusted manufacturer.

Cost Savings

By cutting out intermediaries, we provide highly competitive pricing on our turning inserts. Maximize your budget without sacrificing quality.

Customization Capabilities

Need a unique insert geometry or specialized coating? Our in-house manufacturing allows for tailored solutions to match your exact specifications.

Quality Control

We oversee every step of the production process, ensuring the highest quality standards are met. Trust our inserts for consistent, reliable performance.

Technical Expertise

Our engineers have deep knowledge of turning insert design and applications. Get expert advice and support to optimize your machining processes.

Bulk Order Capacity

We’re equipped to handle large-scale orders efficiently, ensuring you always have the inserts you need, when you need them.

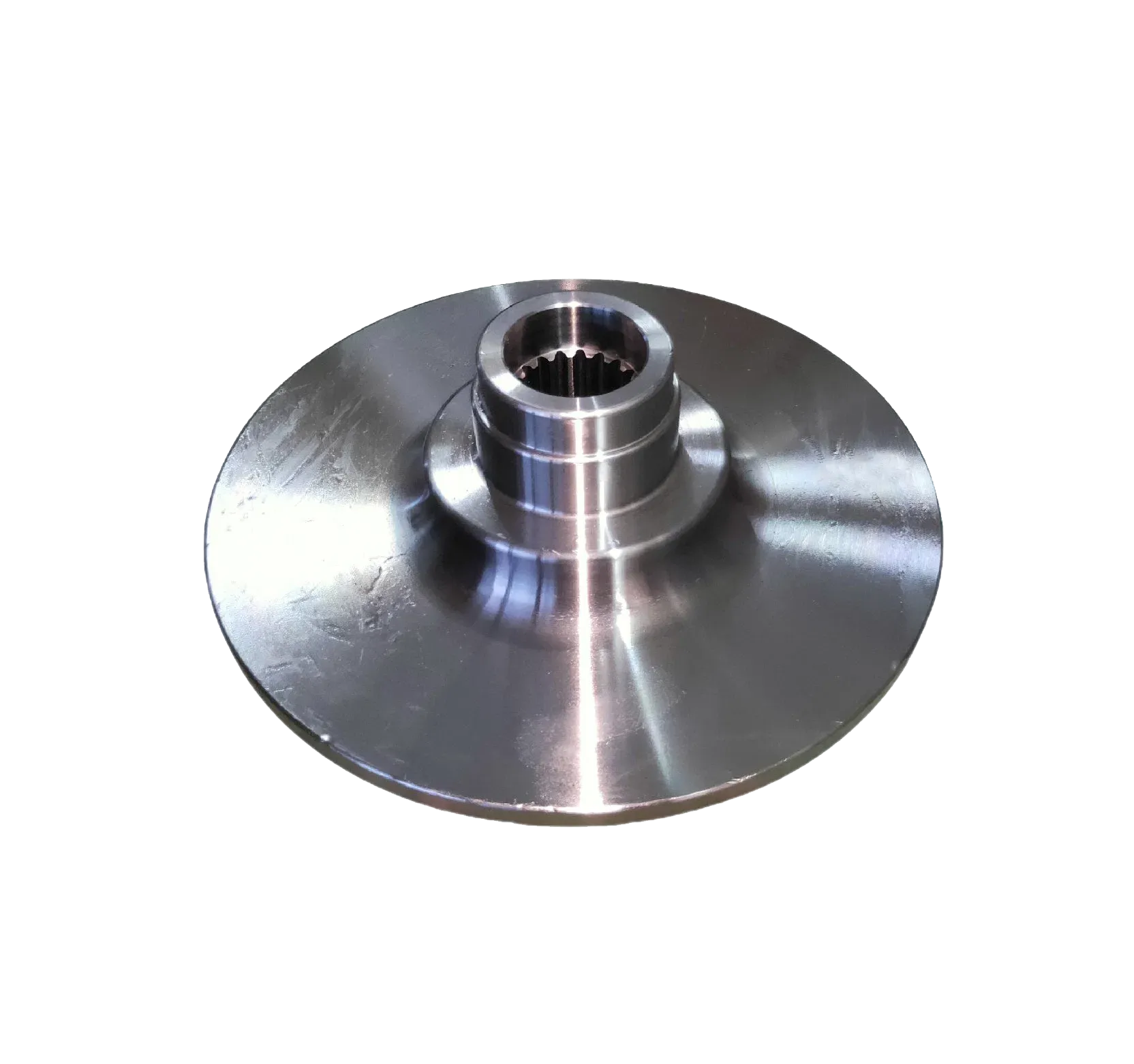

Flange plate

Application-p-type material turning

- Workpieces materials: 40Cr, quenching and tempering

- Machining method: Finishing of end face

- Turning Insert: DNMG150408

- Machining parameters: Vc=338.5m/min,f.-0,14~0.32mm/r,ap=0.2mm

- Cooling method: Water cooling

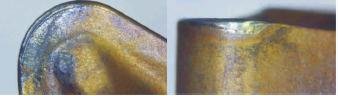

After machining, 200 workpieces, ONMY products have less wear extent on the rear insert face and better surface quality.

Company A

ONMY

Flange plate

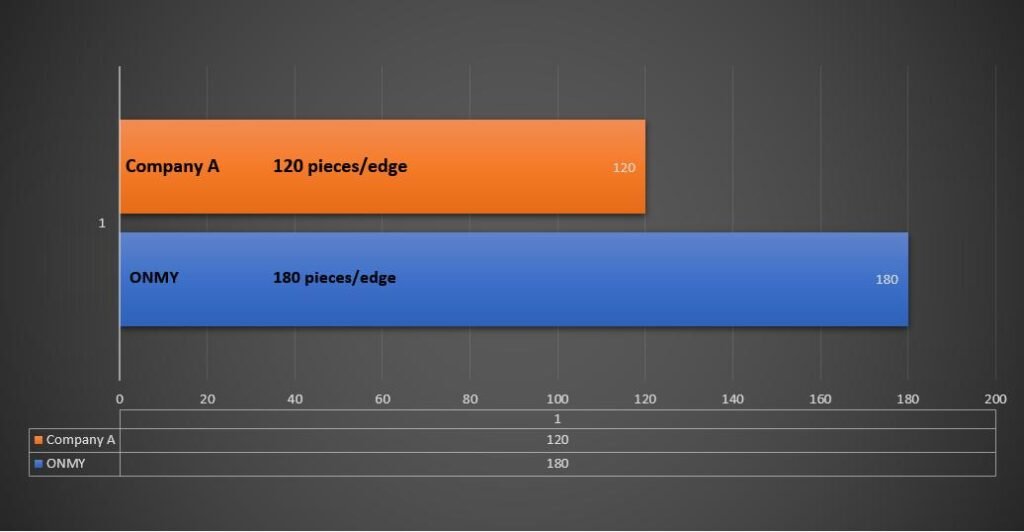

Application-Stainless steel material turning

- Workpieces materials: SUS304

- Machining method: External and end face turning

- Turning Insert: VNMG160408

- Machining parameters: Vc=171~180m/min,fn=0.08mm/r,ap=0.30mm

- Cooling method: Water cooling

With good machined surface quality, ONMY products’ service life is extended by about 50%.

Frequently Asked Questions

We are a turning insert manufacturer with many years of experience, our turning insert factory has 30+ grinding machines, with five Anka grinding machines for more demanding products. The products of our factory are 100% inspected before shipment. Of course we also have a specialised trading company for export.

Yes, our turning inserts are manufactured to meet or exceed industry standards, ensuring high quality and reliability in every product.

Absolutely, we offer custom design services to meet the specific needs and requirements of our customers. Our team of experts can work with you to create tailored solutions for your machining applications.

We have a streamlined production process and efficient logistics system in place to ensure timely delivery of orders. Our team is dedicated to meeting deadlines and providing excellent customer service throughout the entire process.

We take customer satisfaction very seriously and have a dedicated customer support team to handle any post-sales issues or complaints. Simply reach out to us with your concerns, and we will work diligently to resolve them to your satisfaction.

PROFESSIONAL MACHINES PROVIDE HIGH QUALITY LATHE CUTTING INSERTS

We have 15+ fully automatic grinders, 3 five-axis grinders, and a variety of inspection equipment to provide you with the highest quality milling tools.

In addition, we also have several milling machines. Some people may wonder why we need milling machines. It’s because every new product that comes out of our factory equipment must be tested, not just measured for size and blade data with inspection equipment

This way, we can conduct more comprehensive testing to ensure that the quality and performance of the product meet our requirements.