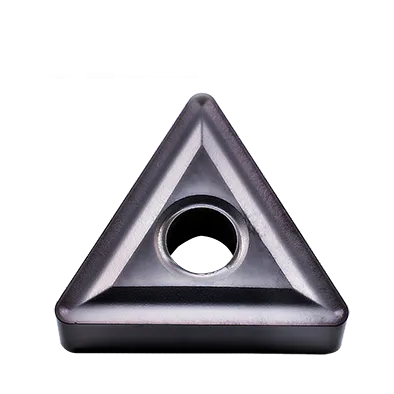

TNMG insert

TNMG insert angle: 60°Triangle carbide insert; 0° Negative Rake Insert and double-sided with chipbreaker;

Breaker Application: Rough machining, Semi-finishing machining, Finish machining;

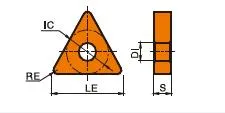

TNMG insert inscribed circle (IC) of 9.525mm/12.7mm, thickness of 4.76mm, and corner (nose) radius of 0.4mm/0.8mm/1.2mm;

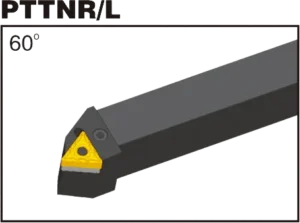

Matching TNMG insert Tool Holder: PTFNR/L,PTTNR/L,PTGNR/L,MTGNR/L,MTJNR/L,MTFNR/L;

TNMG insert specification:(ISO)TNMG1604 insert/TNMG2204 insert/(ANSI)TNMG322 insert/TNMG331 insert/TNMG332 insert/TNMG431 insert/TNMG432 insert;

TNMG Insert can deal with multiple operations by combining different grades;

Virgin material: 100%;

TNMG Insert Meaning

Upgrade your machining with this T-shaped TNMG carbide insert!

Its negative angle design ensures efficient, stable performance.

Flexible sizing means you get the perfect fit for your tools and project needs.

Larger inserts offer even greater stability.

Experience a 4x boost in processing speed compared to old-fashioned welding inserts, plus unbeatable wear resistance, temperature tolerance, anti-corrosion properties, rigidity, cost savings, energy efficiency, and a long working life.

TNMG insert Specification

TNMG Designation

- T: Triangular shape

- N: Negative rake angle (for stronger cutting edge)

- M: Tolerance class (indicates precision)

- G: Chipbreaker and hole type (can vary by manufacturer)

Common TNMG Dimensions

TNMG, like other insert types, use numbers to indicate size:

TNMG 33X: (most common)

- Inscribed Circle (IC): 0.375″ (3/8″)

- Thickness: 0.125″ (1/8″)

- X represents the nose radius (e.g., 1 = 1/32″, 2 = 1/16″)

TNMG 43X:

- Inscribed Circle (IC): 0.5″ (1/2″)

- Thickness: 0.188″ (3/16″)

- X represents the nose radius

Key Features of TNMG Inserts

- Negative Rake Angle: Provides a durable cutting edge, well-suited for tougher materials and interrupted cuts.

- 60° Included Angle: Standard for triangular inserts, used for versatile turning operations.

- Wide Range of Chipbreakers: TNMG inserts often have complex chipbreaker designs, significantly influencing chip formation and control for specific materials and applications.

- Coatings: Commonly coated with materials like TiN, TiCN, AlTiN, and others for longer tool life and wear resistance.

TNMG insert holder

MTJNR/L

carbide TNMG Insert Dimensions (ISO and ANSI)

| TNMG Insert Size | ||||

|---|---|---|---|---|

| ANSI Designation | ISO Designation | Inscribed Circle (IC) | Thickness | Corner Radius |

| TNMG 321 | TNMG 1604 | 1/2" (12.7mm) | 1/8" (3.18mm) | 1/32" (0.8mm) |

| TNMG 322 | TNMG 1604 | 1/2" (12.7mm) | 3/16" (4.76mm) | 1/32" (0.8mm) |

| TNMG 431 | TNMG 2204 | 3/4" (19.05mm) | 1/8" (3.18mm) | 1/32" (0.8mm) |

| TNMG 432 | TNMG 2204 | 3/4" (19.05mm) | 3/16" (4.76mm) | 1/32" (0.8mm) |

| TNMG 433 | TNMG 2206 | 3/4" (19.05mm) | 1/4" (6.35mm) | 1/32" (0.8mm) |

| TNMG 643 | TNMG 32.51 | 1 1/4" (31.75mm) | 1/4" (6.35mm) | 1/32" (0.8mm) |

Example: TNMG 432

- T: Triangular

- N: Negative rake angle

- M: Tolerance class

- G: 60° included angle

- 4: Inscribed circle of 0.5″ (1/2″)

- 3: Thickness of 0.188″ (3/16″)

- 2: Nose radius of 0.0625″ (1/16″) – good for general purpose work

Frequently Asked Questions

Absolutely! Here’s a breakdown of the key differences between TNMG and CNMG inserts, including their shapes, applications, and advantages:

Shape

TNMG: Triangular insert with a 60-degree included angle. Provides three cutting edges.

CNMG: Diamond-shaped insert with an 80-degree included angle. Provides four cutting edges.

Cutting Edge Strength

TNMG: The three cutting edges of the triangular shape offer good versatility, but are slightly less robust compared to a CNMG.

CNMG: The four cutting edges on the diamond shape provide excellent strength and are ideal for heavier machining operations.

Accessibility

CNMG’s combine the flexibility of turning and facing in one tool, as well as a generally tough tool capable of heavy cuts and abuse. If you are doing job-shop work, or rough turning and facing in the same tool, CNMG’s are the way to go. Also, don’t forget that you can use the 100* corner for operations that don’t require you to get into a corner. Think facing cuts for example.

TNMG’s offer the two extra corners, as well a generous bearing surface in the pockets, at the expense of versatility. If you can optimize your tool paths to use the tool exclusively for either facing or turning, I think these are they way to go.

Here’s a step-by-step guide on how to identify the size of a TNMG insert:

1. Understand the TNMG Code:

- TNMG: This part is standard and tells you that it’s a triangular insert with a negative rake angle and some form of hole and chipbreaker design.

- Following Digits: The numbers after “TNMG” are the key to determining size.

2. Decipher the Numeric Code:

Let’s use the common example TNMG 332:

- First Number (3): Indicates the cutting edge length in sixteenths of an inch (3/16″).

- Second Number (3): Represents the thickness of the insert in sixteenths of an inch (3/16″).

- Final Number (2): The nose radius code. A common scale is:

- 1 = 0.0312″ (1/32″)

- 2 = 0.0625″ (1/16″)

3. Know Your Units:

- ANSI: Typically uses imperial measurements (inches) for TNMG sizing.

- ISO: May use metric measurements (millimeters). Example: TNMG 160408 indicates a 12.7mm inscribed circle and 4.76mm thickness.

4. Consult Manufacturer Resources:

For the most accurate and complete information, refer to the documentation for your specific TNMG insert. Manufacturers and suppliers provide detailed size charts and specifications. Here’s how:

- Get the Full Code: Find the complete code on the insert or its packaging.

- Search Online: Use the full code to search the manufacturer’s or supplier’s website/catalog.

Additional Notes:

- Nose radius: This affects surface finish – smaller radii are better for finishing.

- Chipbreaker Design: The ‘G’ in the TNMG code indicates the chipbreaker style and is a crucial factor in chip formation and control. It’s best to consult manufacturer documentation to understand the chipbreaker’s ideal applications.

Let me know the specific code of your TNMG insert, and I can provide its exact dimensions!

Here’s how to identify the inscribed circle (IC) of a TNMG insert:

1. Understand the TNMG Code:

The inscribed circle of a TNMG insert is the diameter of the largest circle that can be drawn inside the triangle of the insert. This core dimension dictates how big of a cut it can take.

2. Decipher the Numeric Code:

There are two main ways the IC is indicated in the TNMG code:

ANSI (Imperial Units):

Take the first number of the size code and divide it by 8.

Example: TNMG 332 – 3/8 = 0.375″ This is the inscribed circle.

ISO (Metric Units):

The IC is often given directly in the code.

Example: TNMG 160408 – 16 represents the inscribed circle of 16mm.

3. Manufacturer Variations:

- Some manufacturers may slightly modify the coding for metric-sized TNMG inserts.

- Always refer to the manufacturer’s or supplier’s documentation for your specific insert to confirm the exact IC.

How to Find Inscribed Circle Information

- Full Designation: Locate the complete TNMG code, including the size, on the insert or its packaging.

- Manufacturer/Supplier Resources: Search the manufacturer’s or supplier’s website for their TNMG catalog or size charts.

Important Note: Remember, the inscribed circle is just one part of the size. The other numbers in the TNMG code define thickness and nose radius, which also need to be understood for proper insert selection.

Let me know the specific TNMG code of your insert, and I’ll tell you its exact inscribed circle!

TNMG inserts are a common type of cutting tool insert used in turning operations on lathes for machining various materials. Here’s what you need to know about them:

Key Features

- Shape: Triangular with three usable cutting edges.

- Negative Rake Angle: The cutting face is angled backward from the cutting edge. This provides a strong, durable edge well-suited for tougher materials and interrupted cuts.

- 60° Included Angle: This standard angle on triangular inserts makes TNMG versatile for various turning applications.

- Chipbreakers: TNMG inserts often have intricate chipbreaker geometries on one or both sides. These chipbreakers greatly influence chip formation, chip flow, and cutting performance.

- Coatings: Inserts are frequently coated with materials such as TiN, AlTiN, and others to improve wear resistance and tool life.

Applications

TNMG inserts excel in these areas:

- Materials: They are widely applicable, particularly for steels, cast iron, and some harder materials due to their negative rake angle.

- Operations: TNMGs handle roughing, semi-finishing, and general-purpose turning tasks depending on the insert’s specific nose radius and chipbreaker design.

Understanding the TNMG Code

The letters and numbers in the TNMG designation provide crucial details:

- T: Triangular shape

- N: Negative rake angle

- M: Tolerance class (refers to manufacturing precision)

- G: Indicates the specific hole and chipbreaker design (varies by manufacturer)

- Numbers:

- Usually, the first number represents cutting edge length in sixteenths of an inch (or directly the inscribed circle in millimeters for ISO codes).

- The second number represents thickness in sixteenths of an inch.

- The last number often indicates the nose radius (smaller means sharper).

Example: TNMG 160408 (ISO)

- Triangular negative rake insert.

- Inscribed circle of 12.7mm.

- Thickness of 4.76mm

- Specific chipbreaker/hole design.

Selecting the Right Insert

Choose a TNMG insert based on:

- Workpiece material

- Type of turning operation (roughing vs. finishing)

- Desired surface finish

- Need for specific chip control

Let me know if you want help interpreting a specific TNMG code or have a particular machining task in mind, and I can suggest suitable insert options!

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

Carbide inserts are some of the most versatile and durable cutting tools available. But how are they made? And what makes them so strong? In this video, we’ll explore the science behind carbide inserts, from the properties of tungsten carbide to the manufacturing process.

Our Production Capability