Your Trusted China Carbide Inserts Producer

Premium China Carbide Inserts for Optimal Performance

Welcome to ONMY Tools, your go-to source for high-quality carbide inserts. As a leading carbide insert supplier, we specialize in providing premium China carbide inserts that meet the most demanding machining requirements. Our extensive range of products, including top-notch turning inserts, ensures that you’ll find the perfect solution for your manufacturing needs.

Welcome To ONMY Tools

In today’s competitive manufacturing landscape, precision is key to success. Carbide inserts play a crucial role in achieving the highest levels of accuracy and efficiency in machining operations. As an experienced China carbide inserts supplier, we understand the critical impact these small but mighty components have on your production processes.

Our China carbide inserts are engineered to deliver exceptional performance, durability, and cost-effectiveness. Whether you’re looking for turning inserts, milling inserts, or specialized solutions, we have the expertise and product range to meet your exact specifications.

Why Choose China ONMY Carbide Inserts ?

Unparalleled Quality and Precision

At ONMY Tools, we take pride in offering carbide inserts that meet the highest standards of quality and precision. Our inserts are manufactured using advanced techniques and premium materials, ensuring consistent performance and longer tool life. Each insert undergoes rigorous quality control checks to guarantee that it meets our exacting standards before reaching your hands.

Comprehensive Range of Products

As a leading carbide insert supplier, we offer an extensive selection of inserts to cater to various machining applications. From general-purpose turning inserts to specialized milling and drilling inserts, our catalog covers a wide spectrum of shapes, sizes, and grades. This diversity allows you to find the perfect insert for your specific needs, optimizing your machining processes and improving overall productivity.

Cost-Effective Solutions

Our position as a trusted China carbide inserts provider allows us to offer highly competitive pricing without compromising on quality. By choosing us as your turning inserts supplier, you benefit from the cost advantages of Chinese manufacturing combined with stringent quality control measures. This enables you to reduce your tooling costs while maintaining the high standards your production demands.

Industries We Serve

As a trusted China carbide inserts supplier, we cater to a wide range of industries, including:

Automotive

Providing inserts for engine components, transmission parts, and more

Aerospace

Supplying high-precision inserts for critical aircraft and spacecraft components

Oil and Gas

Offering durable inserts for drilling equipment and pipeline components

General Manufacturing

Supporting diverse machining needs across various sectors

Medical

Delivering precision inserts for the production of medical devices and implants

Die and Mold

Supplying specialized inserts for intricate mold making

The Advantages of Partnering with Us

- Expert Technical Support

Our team of experienced engineers is always ready to assist you in selecting the right carbide inserts for your specific applications. We provide comprehensive technical support, helping you optimize your machining processes and troubleshoot any issues you may encounter.

- Fast and Reliable Delivery

We understand the importance of timely delivery in maintaining your production schedules. As a responsive carbide insert supplier, we maintain a large inventory of standard inserts and offer quick turnaround times for custom orders. Our efficient logistics network ensures that your orders reach you promptly, minimizing downtime and keeping your operations running smoothly.

- Customization Capabilities

Every manufacturing process is unique, and sometimes off-the-shelf solutions aren’t enough. Our in-house research and development team can work with you to design and produce custom carbide inserts that perfectly match your specific requirements. This flexibility allows you to tackle even the most challenging machining tasks with confidence.

- Competitive Pricing

As a China carbide inserts supplier, we leverage the cost advantages of Chinese manufacturing while maintaining strict quality standards. This allows us to offer you highly competitive prices without compromising on the performance and reliability of our products. By choosing us as your turning inserts supplier, you can significantly reduce your tooling costs and improve your bottom line.

Our Commitment to Quality

Quality is at the heart of everything we do at ONMY TOOLINGS. As a reputable carbide insert supplier, we have implemented rigorous quality control measures throughout our production process. Our manufacturing facilities are equipped with state-of-the-art testing equipment, ensuring that each insert meets our exacting standards before it leaves our premises.

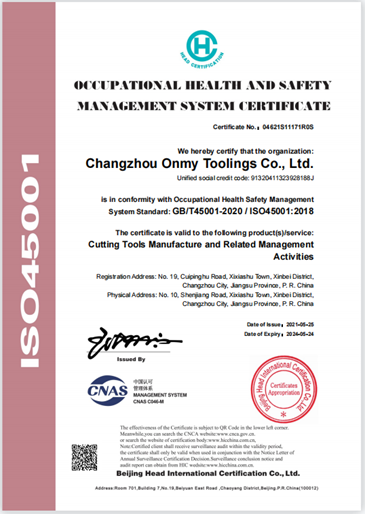

We are proud to hold ISO 9001:2015 and ISO45001 certification, demonstrating our commitment to maintaining a robust quality management system. Additionally, our products comply with international standards such as ANSI and DIN, guaranteeing compatibility and performance across various machining systems.

Our Happy Clients From 30+ Countries

James King

Joanna Foxx

Felicity Trump

Our Ordering Process

Ordering from ONMY Tools is simple and straightforward:

- Browse our online catalog or contact our sales team for product information.

- Select the desired carbide inserts or request a custom quote.

- Provide your specific requirements and quantity needed.

- Review and confirm your order details.

- Choose your preferred payment method and complete the transaction.

- Receive order confirmation and estimated delivery date.

- Track your shipment and prepare for arrival.

For large or recurring orders, we offer streamlined processes and potential volume discounts. Contact our sales team to discuss your specific needs.

Your Reliable China carbide Inserts Producer

Ready to experience the difference of working with a top-tier carbide insert supplier? We’re here to assist you