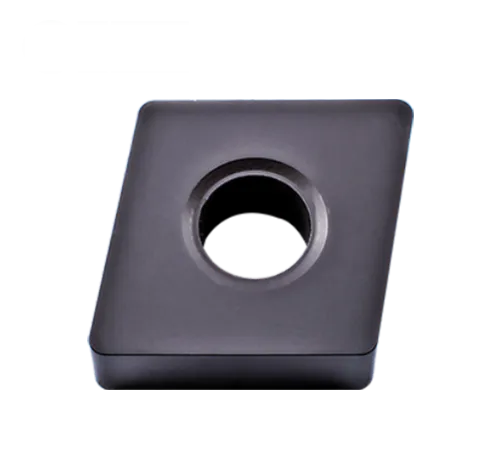

CNMA insert

CNMA insert angle:0° Negative rake insert and no chipbreaker;

80° rhombic turning insert;

Primary workpiece material: Hard material; cast Iron; steel;

Primary workpiece material code: P; H; K

Insert holding method: Pin; Clamp;

Breaker application: Roughing, semi-finishing, finishing;

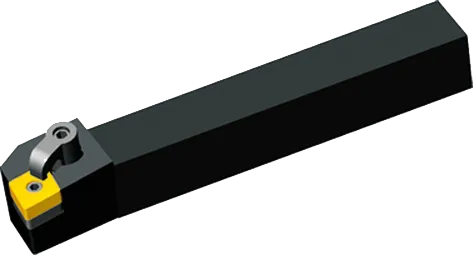

Matching cnma insert tool holder: PCBNR/L, PCLNR/L, MCLNR/L,MCBNR/L;

Grade: Both PVD and CVD;

Material : Tungsten Carbide;

CNMA insert tool holder

MCLNR/L

CNMA insert Introduction:

CNMA Carbide Inserts: The Essentials

- Shape: Rhombic (diamond) with an 80-degree included angle.

- Clearance Angle: 0 degrees

- Cutting Edges: Double-sided, offering two cutting edges per insert for cost-effectiveness.

- Chipbreaker Geometries: Diverse range of chipbreaker styles from various manufacturers are available. These are tailored to specific materials and machining operations (roughing, finishing, etc.).

- Key Uses: Primarily used for general turning operations and some facing work on a range of materials.

Common Materials CNMA Inserts are Used For

- Cast Iron: Suitable for many cast iron applications.

Advantages of CNMA Inserts

- Cost-effective: Due to their double-sided design, offering longer tool life per insert.

- Versatile: The range of grades and chipbreakers make them suitable for many machining applications.

- Strong Geometric Shape: The 80-degree diamond shape provides strength and rigidity for their size.

Important Considerations

- Match the Grade to Your Material: Choosing the right insert coating and substrate composition is crucial for optimal tool life and performance in the specific material you’re cutting.

- Select the Right Chipbreaker: The chipbreaker geometry significantly influences how chips are formed and broken. It should be chosen based on the material and type of machining operation.

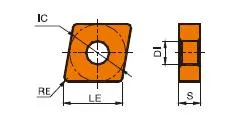

CNMA Insert Dimensions (ISO)

| TYPE | CNMA INSERT DIAMENTIONS(mm) | ||||

|---|---|---|---|---|---|

| LE | IC | S | DI | RE | |

| CNMA120404 | 12.9 | 12.7 | 4.76 | 5.16 | 0.4 |

| CNMA120408 | 12.9 | 12.7 | 4.76 | 5.16 | 0.8 |

| CNMA120412 | 12.9 | 12.7 | 4.76 | 5.16 | 1.2 |

| CNMA120416 | 12.9 | 12.7 | 4.76 | 5.16 | 1.6 |

| CNMA160608 | 16.1 | 15.875 | 6.35 | 6.35 | 0.8 |

| CNMA160612 | 16.1 | 15.875 | 6.35 | 6.35 | 1.2 |

| CNMA160616 | 16.1 | 15.875 | 6.35 | 6.35 | 1.6 |

| CNMA190612 | 19.3 | 19.05 | 6.35 | 7.94 | 1.2 |

| CNMA190616 | 19.3 | 19.05 | 6.35 | 7.94 | 1.6 |

Example: CNMA 120408

- 12: Inscribed Circle (IC) of 12.7mm (approx. 0.5 inches)

- 04: Thickness of 4.76mm (approx. 0.187 inches)

- 08: Corner radius of 0.8mm (approx. 0.031 inches)

Key Dimensions

Inscribed Circle (IC): The diameter of the largest circle that fits within the insert. Common IC sizes include:

- 12.7mm (0.5″)

- 16mm (0.63″)

- 19.05mm (0.75″)

Thickness: Impacts insert strength and the number of usable cutting edges. Common thicknesses include:

- 3.18mm (0.125″)

- 4.76mm (0.187″)

- 6.35mm (0.25″)

Corner Radius: Affects surface finish and strength at the cutting edge. Common sizes include:

- 0.4mm (0.016″)

- 0.8mm (0.031″)

- 1.2mm (0.047″)

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

Carbide inserts are some of the most versatile and durable cutting tools available. But how are they made? And what makes them so strong? In this video, we’ll explore the science behind carbide inserts, from the properties of tungsten carbide to the manufacturing process.

Our Production Capability