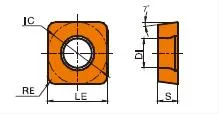

SCGX insert

SCGX insert angle: 90° Square ,7° Positive Rake Insert with single-sided Chipbreaker;

Screw-On Inserts;

High Polish Square Turning Insert for Aluminum Applications;

Square carbide insert;

Breaker Application: Semi-finishing & Finishing machining;

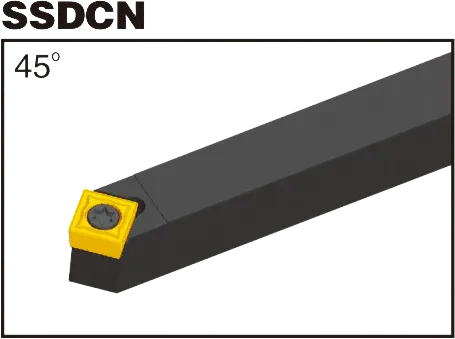

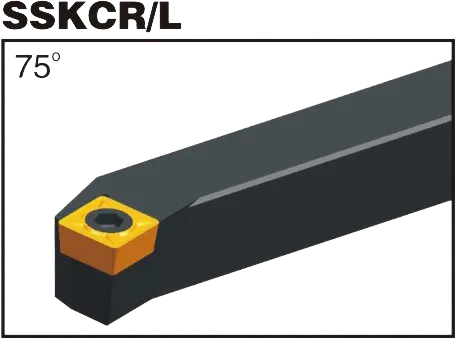

Matching TurningTool Holder: SSDCN,SSKCR/L;

SCGX Insert can deal with multiple operations by combining different chip breakers and grades;

Material : Tungsten Carbide;

SCGX insert specification

SCGX insert is the specialist in external turning. The function of a chip breaker is to improve chip control and to reduce cutting resistance.

A better balance between the two will increase the machining performance.

If chips can be broken into suitable lengths by the chip breaker, they will not wrap around the workpiece, vibration will decrease and tools will not be so easily damaged.

Chip breakers also affect cutting resistance.

Reduced cutting resistance can avoid chipping and fracturing of the cutting edge caused by vibration.

Additionally, lower cutting resistance can decrease the load and heat, and can delay the development of tool wear.

SCGX insert Meaning

Understanding the SCGX Insert Code

- S: Shape: Square

- C: Clearance Angle: 7 degrees (positive)

- G: Tolerance: Medium tolerance is standard, though other precision tolerances might be available.

- X: Chipbreaker style & Hole Configuration. This letter designates the specific chipbreaker geometry and whether the insert has a hole or not.

- Numerical Digits:

- First Two Digits: Inscribed circle (IC) diameter in millimeters. To obtain the approximate inch equivalent, divide this number by 25.4.

- Next Two Digits: Thickness in millimeters. Divide by 25.4 to convert to inches.

- Last Two Digits: Corner radius in millimeters. To convert to inches, divide by 25.4.

SCGX insert holder

SCGX Insert Dimensions (ISO)

| ISO Designation | Inscribed Circle (IC) | Thickness | Corner Radius |

|---|---|---|---|

| SCGX 09T302 | 9.52mm (0.375") | 3.18mm (0.125") | 0.2mm (0.008") |

| SCGX 09T304 | 9.52mm (0.375") | 3.18mm (0.125") | 0.4mm (0.016") |

| SCGX 09T308 | 9.52mm (0.375") | 3.18mm (0.125") | 0.8mm (0.031") |

| SCGX 120404 | 12.7mm (0.5") | 4.76mm (0.187") | 0.4mm (0.016") |

| SCGX 120408 | 12.7mm (0.5") | 4.76mm (0.187") | 0.8mm (0.031") |

Example: SCGX 09T308

- Square shape

- 7-degree positive clearance angle

- Medium tolerance

- Manufacturer-specific chipbreaker and hole configuration

- 9.52mm inscribed circle diameter (approx. 0.375″ in inches)

- 3.18mm thick (approx. 0.125″ in inches)

- 0.8mm corner radius (approx. 0.031″ in inches).

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

Carbide inserts are some of the most versatile and durable cutting tools available. But how are they made? And what makes them so strong? In this video, we’ll explore the science behind carbide inserts, from the properties of tungsten carbide to the manufacturing process.

Our Production Capability