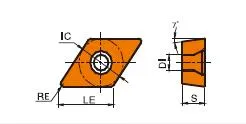

DCGT insert

DCGT insert angle:7° Positive rake insert with a single-sided Chipbreaker;

55° Rhombic turning insert;

Primary workpiece material: Aluminium;

Breaker application: Semi-finshing and finishing machining;

Matching turning tool holder: SDQCR/L, SDUCR/L;

DCGT insert dimensions:DCGT0702/DCGT11T3;

Material : Tungsten carbide;

DCGT insert specification

Finishing geometry with high positive rake face for chip control in long chipping materials.

DCGT insert tool holder

DCGT insert Introduction

- D: Shape. Rhombic (diamond) with a 55-degree included angle.

- C: Clearance Angle. 7 degrees (positive).

- G: Tolerance. Medium (‘G’) is standard, though other precision tolerances exist.

- T: Chipbreaker style & Hole Configuration. This letter designates the specific chipbreaker geometry and whether the insert has a hole or not. Chipbreaker variations are numerous and manufacturer-specific.

- Numerical Digits:

- First Two Digits: Inscribed circle (IC) diameter in millimeters. To obtain the approximate inch equivalent, divide this number by 25.4.

- Next Two Digits: Thickness in millimeters. Divide by 25.4 to convert to inches.

- Last Two Digits: Nose radius in millimeters. To convert to inches, divide by 25.4.

DCGT Insert Dimensions (ISO)

| ISO Designation | Inscribed Circle (IC) | Thickness | Corner Radius |

|---|---|---|---|

| DCGT 070202 | 7.94mm (0.313") | 2.38mm (0.094") | 0.2mm (0.008") |

| DCGT 070204 | 7.94mm (0.313") | 2.38mm (0.094") | 0.4mm (0.016") |

| DCGT 11T302 | 11mm (0.433") | 3.18mm (0.125") | 0.2mm (0.008") |

| DCGT 11T304 | 11mm (0.433") | 3.18mm (0.125") | 0.4mm (0.016") |

| DCGT 11T308 | 11mm (0.433") | 3.18mm (0.125") | 0.8mm (0.031") |

Example: DCGT 11T308

- Rhombic (diamond) shape with a 55-degree included angle

- 7-degree positive clearance angle

- Medium tolerance

- Manufacturer-specific chipbreaker and hole configuration

- 11mm inscribed circle diameter (approx. 0.43″ in inches)

- 3.18mm thick (approx. 0.125″ in inches)

- 0.8mm nose radius (approx. 0.031″ in inches)

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

Carbide inserts are some of the most versatile and durable cutting tools available. But how are they made? And what makes them so strong? In this video, we’ll explore the science behind carbide inserts, from the properties of tungsten carbide to the manufacturing process.

Our Production Capability