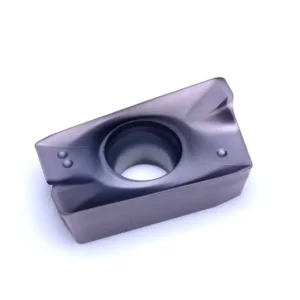

APMT insert

As a leading supplier of cutting-edge milling solutions, we offer a comprehensive range of APMT inserts designed for maximum efficiency and durability in large-scale industrial applications. Our products cater to wholesale customers seeking top-quality milling tools for their operations.

Insert Specification Guide

- A: Insert shape (rhombic 85°)

- P: Relief angle (11°)

- M: Medium tolerance class

- T: Insert features (hole and chip breaker)

Related articles on APMT vs. APKT.

Dimensions is crucial for optimal performance

- APMT1604:

- Inscribed Circle (IC): 9.525 mm

- Thickness: 4.76 mm

- APMT 1135:

- Inscribed Circle (IC): 6.35 mm

- Thickness: 3.18 mm

APMT Insert Cutter Compatibility

| ISO Code | Size | L (Length) | W (Width) | S (Thickness) | R (Radius) | Chipbreaker | Description | Recommended Grades |

|---|---|---|---|---|---|---|---|---|

| APMT1135PDER | 1135 | 11.3 mm | 6.25 mm | 3.6 mm | 0.8 | General | Through Groove Robust structure, suitable for mixed machining of various materials. | D7320, D570 |

| APMT1135PDER-ZL | 1135 | 11.3 mm | 6.25 mm | 3.6 mm | 0.8 | -ZL | Light Cutting Special geometry design to reduce cutting resistance. | D7320, D9920S |

| APMT1135PDER-M2 | 1135 | 11.3 mm | 6.25 mm | 3.6 mm | 0.8 | -M2 | Finishing / Semi-finishing Low cutting force, sharp edge, ideal for Stainless and Steel. | D530,D570,D580,D7230,D8420A |

| APMT1135PDER-H2 | 1135 | 11.3 mm | 6.25 mm | 3.6 mm | 0.8 | -H2 | Roughing Reinforced edge design, impact resistant, for harsh conditions. | D530,D570,D580,D7230,D8420A |

| APMT1604PDER | 1604 | 17.42 mm | 9.33 mm | 5.2 mm* | 0.8 | General | Through GrooveStandard geometry for general face and shoulder milling. | D7320, D570 |

| APMT1604PDER-M2 | 1604 | 17.25 mm | 9.25 mm | 4.76 mm | 0.8 | -M2 | Finishing / Semi-finishing Sharp cutting, good chip evacuation, reduces built-up edge. | D530,D570,D580,D7230,D8420A |

| APMT1604PDER-H2 | 1604 | 17.25 mm | 9.25 mm | 4.76 mm | 0.8 | -H2 | Roughing High edge strength, chipping resistant, suitable for high feed. | D530,D570,D580,D7230,D8420A |

| APMT1604PDER-ZL | 1604 | 17.42 mm | 9.33 mm | 5.2 mm | 0.8 | -ZL | Light Cutting Special geometry design to reduce cutting resistance. | D7320, D9920S |

Our inserts are designed to fit a wide range of milling cutters, ensuring versatility across various machining operations:

- Face milling cutters

- Shoulder milling cutters

- High-feed milling cutters

The right APMT insert cutter combination can significantly enhance your milling efficiency and output quality.

Applications

Inserts excel in various industrial milling operations:

- General face milling

- Shoulder milling

- Roughing and finishing operations

- Suitable for materials including steel, stainless steel, and cast iron

Optimizing Your Milling Operations

Selecting the right APMT insert can significantly impact your milling efficiency:

- Consider your material: Different grades are available for various materials.

- Evaluate your milling operation: Choose between APMT1604 and APMT 1135 based on your specific needs.

- Assess your required finish: Select the appropriate corner radius for your desired surface quality.

Why Choose Our Inserts?

Superior quality

All our inserts undergo rigorous quality control.

Competitive wholesale pricing

Bulk orders benefit from attractive discounts.

Comprehensive range

From APMT1604 to APMT 1135, we have the right insert for your needs.

Technical support

Our team of experts is available to help you choose the perfect APMT insert specification for your application.

Frequently Asked Questions

What are the key differences between APMT1604 and APMT 1135 inserts?

APMT1604 and APMT 1135 inserts differ primarily in their dimensions and applications: APMT1604: Larger size with a 9.525 mm inscribed circle 4.76 mm thickness Ideal for general-purpose milling and heavier cuts Suitable for larger milling cutters APMT 1135: Smaller size with a 6.35 mm inscribed circle 3.18 mm thickness Better for more precise milling operations Suitable for smaller milling cutters or when working with tighter tolerances The choice between these depends on your specific milling requirements, machine capabilities, and the scale of your operations.

Can you provide custom APMT insert cutters for specialized applications?

Yes, we offer customization services for APMT insert cutters to meet specific industrial requirements. This includes: Custom APMT insert dimensions for unique milling challenges Specialized coatings for extreme wear resistance or specific materials Custom edge preparations for particular applications For wholesale customers with specialized needs, we can work with you to develop APMT insert cutters tailored to your exact specifications, ensuring optimal performance in your unique milling processes.

How do APMT insert specifications affect milling performance?

Shape (A): The rhombic 85° shape provides stability and strength for various milling operations. Relief angle (P): The 11° relief angle ensures proper chip evacuation and reduces friction. Tolerance class (M): Medium tolerance ensures consistent performance across inserts. Features (T): The hole and chip breaker improve insert mounting security and chip control. These specifications affect cutting forces, tool life, surface finish quality, and overall machining efficiency. Choosing the right APMT insert specification for your specific application is crucial for optimal performance in large-scale operations.

What factors should I consider when choosing APMT insert dimensions for my operation?

When selecting APMT insert dimensions, consider the following factors: Milling cutter size: Ensure compatibility between the insert and your existing equipment. Material being machined: Different materials may require specific insert grades or coatings. Depth of cut and feed rates: Larger APMT insert dimensions like APMT1604 may be better for heavier cuts. Surface finish requirements: The corner radius of the insert affects the final surface quality. Machine power and stability: Ensure your machinery can handle the cutting forces of the chosen insert size. Production volume: Consider tool life and changeover time for your production scale. Cost-effectiveness: Evaluate the balance between insert price and performance for your wholesale needs. By carefully considering these factors, you can choose the optimal APMT insert dimensions to maximize efficiency and quality in your large-scale milling operations.

Our Production Capability