Quick guide

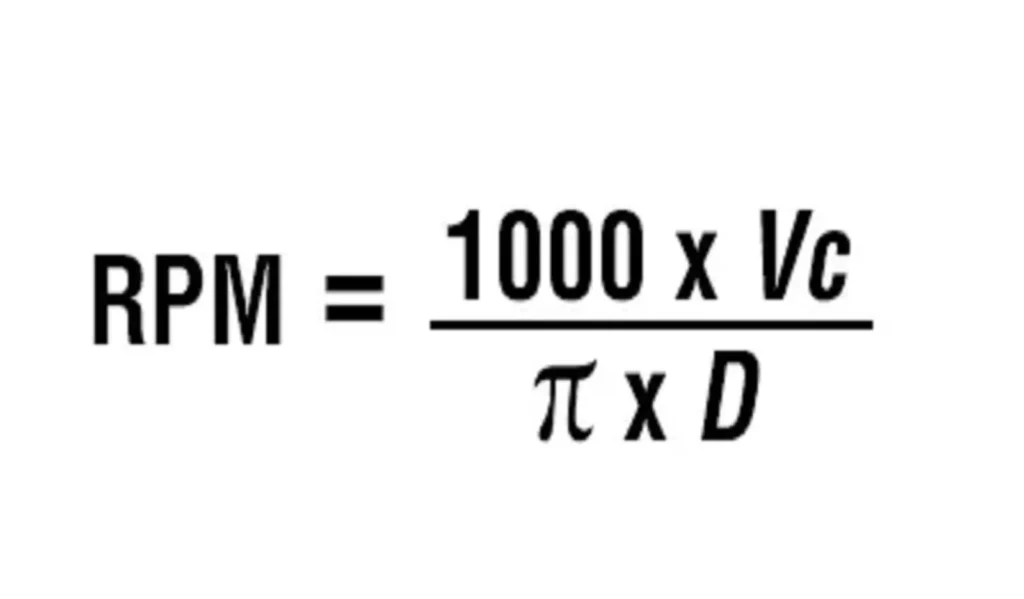

- Calculation formula:RPM = (Cutting speed x 1000) / (π x Cutter diameter)

- Cutting speed: the speed at which the milling cutter is cutting through the material, measured in m/min or ft/min.

- π: the mathematical constant pi (3.14).

- Cutter diameter: the diameter of the milling cutter, measured in millimeters (mm) or inches (in).

Want to know more about milling cutter rotation speed? Read on below!

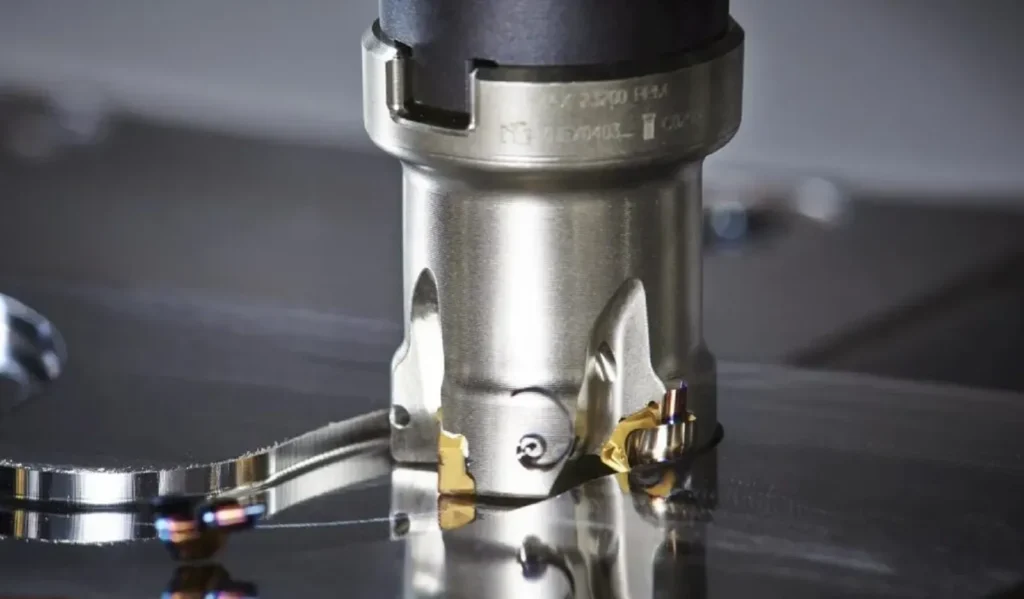

The milling cutter speed is a crucial factor in the machining process. It determines the rate at which the tool rotates and the material is cut. Accurate calculation of milling cutter speed is essential to achieve efficient and safe machining operations. In this article we will discuss the basics of milling cutter speeds, how they are calculated, and the factors that influence them.

Method for calculating the speed of a milling cutter

To calculate the milling speed, you need to know the cutting speed and the diameter of the milling cutter.

The cutting speed can be calculated using the formula:

Cutting speed = (Feed rate x Number of teeth) / (π x Cutter diameter)

- Feed rate: the distance the material moves in one revolution of the cutter, measured in millimeters per minute (mm/min) or inches per minute (in/min).

- A number of teeth: the number of cutting edges on the milling cutter.

Once you have the cutting speed and milling cutter diameter, you can use the above formula to calculate RPM.

Factors affecting the speed of the milling cutter

Hardness and toughness of the material being cut: harder and tougher materials require slower cutting speeds.

Type and nature of milling cutter material: different materials have different properties that can affect cutting speeds.

Depth of cut and feed: deeper cuts and higher feed rates require slower cutting speeds.

Methods for optimizing the speed of milling cutters

Optimizing the speed of the milling cutter can help to improve machining efficiency and reduce tool wear.

Optimization of cutting parameters: adjust cutting speed, feed rate and depth of cut for optimum results.

Selection and replacement of milling cutters: Select the right type and size of milling cutters and replace worn cutters regularly.

Optimise lubrication and cooling: providing adequate lubrication and cooling can help to reduce tool wear and improve machining efficiency.

Safety precautions for milling cutter speed

The milling cutter speed can be dangerous if not used correctly. To ensure safety, a number of precautions should be taken, including:

Knowing the maximum RPM of the milling cutter and not exceeding it.

Wearing appropriate personal protective equipment (PPE), such as safety glasses and gloves.

Follow safe operating procedures, including locking the machine before changing tools or making adjustments.

how to calculate rpm of milling cutter FAQ

Would these speeds equate to bandsaw blade speeds? How would you work that out?

Bandsaw blade speeds seem to be a bit higher, probably because each tooth is contact with the material very briefly. You can find charts all over the interwebs with blade speeds. I’d recommend using the one provided by your blade’s manufacturer.

To clarify for metric. Say I have a 1” (24.4mm) dia alloy bar. The calculation would be 45000/(3.142×25.4)=564rpm. If I was working in imperial it would be 150×4/1=600rpm?

The difference is because the 4 in the imperial formula is an approximation of 3.82. If you do the math with that it comes out to 573rpm

If you were using an end mill with multiple flutes how do you calculate?

The RPM is not affected by the number of flutes, only by the diameter and the material being cut. Flutes do have an effect on the feed rate.

How is the cutting speed determined?

The cutting speed depends on the hardness and toughness of the material to be cut, as well as the material and shape of the milling cutter. This can be calculated by referring to the cutting speed table or by using the formula.

How is the diameter of the milling cutter determined?

The diameter of the milling cutter is usually stamped on the tool or, if not available, can be measured using calipers or micrometer calipers.

How is the number of teeth of a milling cutter determined?

The number of teeth of a milling cutter is usually printed on the tool or, if not available, can be measured using a magnifying glass or by calculating the number of teeth.

How is the feed rate determined?

The feed rate depends on the depth of the cut, the width of cut and the cutting speed. This can be calculated by referring to the feed rate table or by using the formula.

How do I select the milling cutter speed?

The speed of the milling cutter should be determined according to the cutting material, the material and shape of the milling cutter, the depth of cut and the feed rate. This can be calculated by referring to the milling cutter speed table or by using the formulae.

How can I avoid excessive milling cutter speed?

Excessive milling cutter speed can lead to tool wear and danger. The appropriate milling cutter speed should be determined according to the material and tool characteristics and ensure that the maximum RPM of the milling cutter is not exceeded.

How do I maintain the life of my milling cutter?

Choose the right type and size of milling cutter and replace worn cutters regularly. At the same time, optimizing cutting parameters and providing adequate lubrication and cooling can help to reduce tool wear.