CCMT Insert Holder

A CCMT Insert Holder is a widely used turning tool holder specifically designed to securely clamp CCMT style indexable cutting inserts. The ISO designation “CCMT” indicates a rhombic-shaped insert with an 80-degree nose angle, a positive rake angle, a clearance angle, and a central mounting hole. The positive rake angle is a key feature, making these inserts ideal for light to medium machining operations, including finishing and semi-finishing of various materials, particularly softer or more ductile ones like aluminum, stainless steel, and low-carbon steel. The positive rake reduces cutting forces and heat generation, leading to improved surface finishes and reduced power consumption.

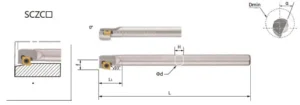

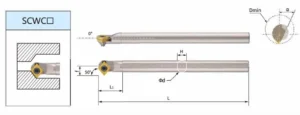

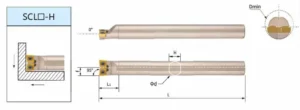

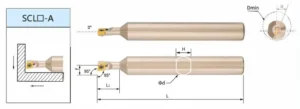

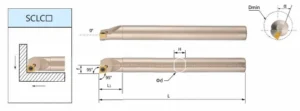

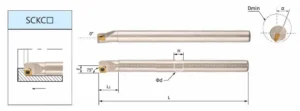

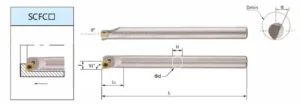

The primary function of a CCMT Insert Holder is to provide a stable and accurately positioned platform for the CCMT insert. This ensures precise material removal and excellent surface finishes. The holder features a precision-machined pocket that matches the specific shape and dimensions of the CCMT insert, allowing for secure and repeatable clamping, typically achieved with a screw or lever mechanism. This robust clamping prevents insert movement and vibration during machining, which is crucial for achieving high-quality results, especially in finishing passes.

CCMT inserts are favored for their ability to produce good surface finishes with relatively low cutting forces. They offer two cutting edges per side, totaling four usable edges per insert, providing good tool life and cost-effectiveness. The corresponding CCMT Insert Holders are designed for ease of use, enabling quick and straightforward insert changes, minimizing machine downtime. Available in various shank sizes and configurations to suit different machine tool types and application needs, CCMT Insert Tool Holders are a valuable asset in precision machining environments where good surface finish and lower cutting forces are desired.

Frequently Asked Questions

“CCMT” is an ISO designation for a rhombic-shaped cutting insert with an 80-degree nose angle and a positive rake angle.

It holds CCMT inserts, which are rhombic with an 80-degree nose angle and a positive rake.

Light to medium machining operations, including finishing and semi-finishing of softer or more ductile materials.

Positive rake angle reduces cutting forces and heat, leading to better surface finishes and lower power consumption.

Consider the shank size needed for your machine, the type of turning operation, the material you are machining, and the required lead angle.

Common sizes include 1/2″, 5/8″, 3/4″, 1″, and metric equivalents, to fit various machine tool holders.

Generally not recommended for heavy roughing due to the positive rake angle which might make the cutting edge less robust compared to negative rake inserts.

Aluminum, stainless steel, low-carbon steel, and other softer or more ductile materials where a good surface finish is desired.

High precision in the insert pocket, secure and reliable clamping, good build quality for stability, and compatibility with your machine and CCMT inserts.

Contact Us for Your Tool Holders

Please note: We are a wholesale supplier and have minimum order quantities.