- We can offer a wide selection of holders made of S (alloy steel), H (high-speed steel), C (carbide), D (spring steel).

- Durable and Strong Construction: The turning tool holder boasts a robust design with a hardness of hrc92, ensuring long-lasting performance and reliability in heavy-duty applications.

- Customization Options: As a provider of OEM, ODM, and OBM services, we offer tailored solutions to meet the specific requirements of customers, including customized tooling and packaging.

- High-Quality Material: Crafted from high-quality spring steel, this turning tool holder features a PVD coating for enhanced durability and resistance to wear and tear.

- Versatile Application: Designed for use with CNC lathe machines, this turning tool holder is ideal for a wide range of industries, including manufacturing, engineering, and production.

- Convenient Packaging: Each tool holder is carefully packaged in a plastic box, ensuring safe and secure transportation, with a minimum order quantity of 1 piece available.

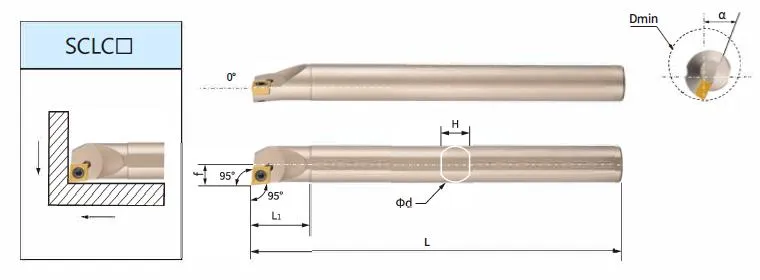

| Model | Size(mm) | Insert | Screw | Wrench | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Left | Right | Φ Dmin | Φd | L | L1 | H | f | a° | |||

| S06K-SCLCL06 | S06K-SCLCR06 | 9 | 6 | 125 | 12 | 5.2 | 4.5 | 15° | CC□□0602□□ | M2.5×6 | T8 |

| S07K-SCLCL06 | S07K-SCLCR06 | 9 | 7 | 125 | 14 | 6.2 | 4.5 | 15° | |||

| S08K-SCLCL06 | S08K-SCLCR06 | 10 | 8 | 125 | 14 | 7 | 4.6 | 12° | |||

| S10K-SCLCL06 | S10K-SCLCR06 | 12 | 10 | 125 | 14 | 9 | 5.6 | 12° | |||

| S12M-SCLCL06 | S12M-SCLCR06 | 14 | 12 | 150 | 16 | 11 | 7 | 10° | |||

| S14N-SCLCL06 | S14N-SCLCR06 | 16 | 14 | 160 | 18 | 13 | 8 | 10° | |||

| S16Q-SCLCL06 | S16Q-SCLCR06 | 18 | 16 | 180 | 32 | 14.8 | 9 | 8° | |||

| S20R-SCLCL06 | S20R-SCLCR06 | 23 | 20 | 200 | 35 | 18.6 | 11.5 | 6° | |||

| S08K-SCLCL09 | S08K-SCLCR09 | 13 | 8 | 125 | 16 | 7 | 7.5 | 15° | CC□□09T3□□ | M4x6 | T15 |

| S10K-SCLCL09 | S10K-SCLCR09 | 13 | 10 | 125 | 20 | 9 | 7 | 15° | |||

| S12M-SCLCL09 | S12M-SCLCR09 | 14 | 12 | 150 | 25 | 11 | 7 | 12° | M4x8 | ||

| S14N-SCLCL09 | S14N-SCLCR09 | 17 | 14 | 160 | 25 | 13 | 8.2 | 10° | |||

| S16Q-SCLCL09 | S16Q-SCLCR09 | 18 | 16 | 180 | 32 | 14.8 | 9 | 8° | |||

| S18Q-SCLCL09 | S18Q-SCLCR09 | 20 | 18 20 | 180 | 35 | 16.6 | 10 | 6° | |||

| S20R-SCLCL09 | S20R-SCLCR09 | 23 | 200 | 35 | 18.6 | 11.5 | 6* | M4x10 | |||

| S25S-SCLCL09 | S25S-SCLCR09 | 28 | 25 | 250 | 45 | 23 | 14.5 | 6° | |||

| S32T-SCLCL09 | S32T-SCLCR09 | 38 | 32 | 300 | 45 | 30 | 20 | 4° | |||

| S40T-SCLCL09 | S40T-SCLCR09 | 46 | 40 | 300 | 55 | 37 | 24 | 4° | |||

| S20R-SCLCL12 | S20R-SCLCR12 | 24 | 20 | 200 | 30 | 18.6 | 12 | 10° | CC□□1204□□ | M5x10 | T20 |

| S25S-SCLCL12 | S25S-SCLCR12 | 29 | 25 | 250 | 38 | 23 | 14.5 | 6° | M5x12 | ||

| S32T-SCLCL12 | S32T-SCLCR12 | 38 | 32 | 300 | 45 | 30 | 20 | 4° | |||

| S40T-SCLCL12 | S40T-SCLCR12 | 46 | 40 | 300 | 45 | 37 | 24 | 4° | |||

| S50V-SCLCL12 | S50V-SCLCR12 | 57 | 50 | 400 | 60 | 47 | 30 | 2° | |||