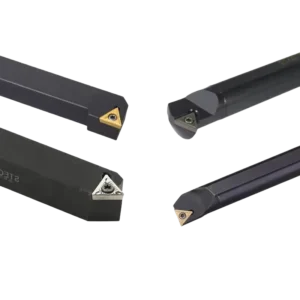

Turning Tool Holder

A Turning Tool Holder is a critical component in machining operations, serving as the interface between the cutting insert and the machine tool. Its primary function is to securely clamp and precisely position the cutting insert, providing the necessary rigidity and stability for accurate material removal during turning processes. Whether used on conventional lathes or advanced CNC machines, the turning tool holder plays a vital role in achieving the desired part dimensions and surface finish.

In the realm of automated manufacturing, the cnc turning tool holder is indispensable. These holders are designed for rapid and accurate tool changes, essential for efficient CNC machining cycles. There are various cnc turning tool holder types, including external turning holders, internal boring bar holders, face grooving holders, threading holders, and cut-off tool holders, each tailored for specific operations. The selection of the appropriate holder depends on the machining task, workpiece material, and the type of CNC machine being used.

For traditional machining on lathes, the lathe turning tool holder performs a similar function, providing a stable platform for the cutting insert. These holders also come in different styles, such as straight, angled, and indexable types, to accommodate various turning requirements. Understanding the iso turning tool holder nomenclature is crucial for selecting the correct holder. This standardized system uses a series of letters and numbers to define the holder’s style, shank size, insert shape, cutting direction, and other key features, ensuring compatibility and proper application.

Beyond standard holders, specialized types like the polygon turning tool holder offer unique advantages. These holders feature a polygon-shaped interface with the machine spindle, providing enhanced rigidity and improved power transmission, particularly beneficial for heavy-duty turning operations. In essence, the Turning Tool Holder is a fundamental element that directly impacts the efficiency, accuracy, and quality of turning operations across a wide spectrum of machining applications.

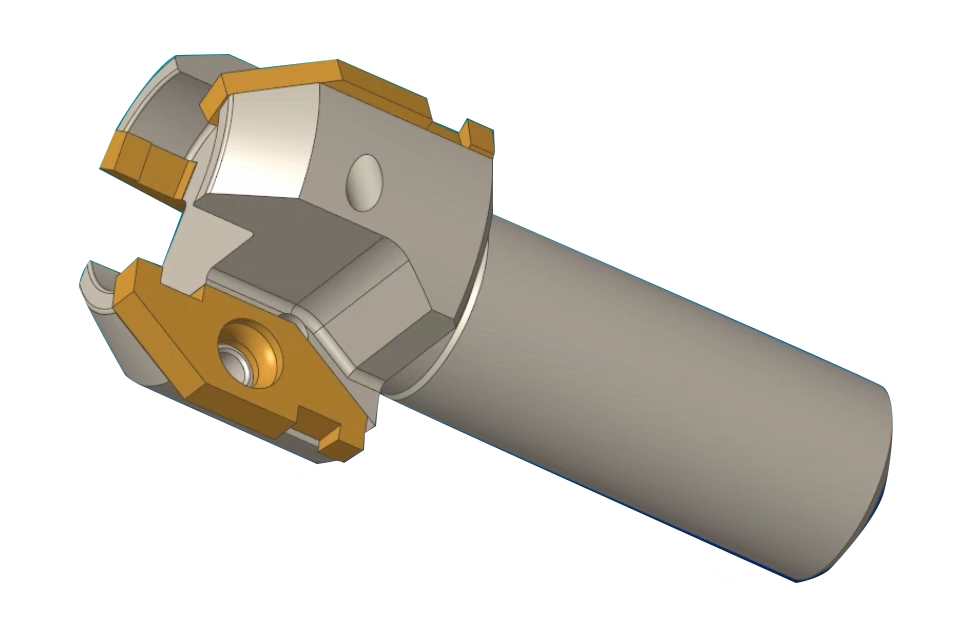

Boring Bars

Boring bars are rigid cutting tools used to enlarge or finish existing holes to precise internal diameters.

CCMT Insert Holder

CCMT insert holders securely clamp CCMT rhombic inserts with a positive rake for smooth, light-to-medium turning operations.

CNMG Insert Tool Holder

CNMG insert tool holders securely hold CNMG rhombic inserts, typically used for medium to heavy-duty turning operations.

Cut-Off Tool Holder

Cut-off tool holders rigidly support thin blades to precisely part off or cut through rotating workpieces on a lathe.

DCMT Insert Holder

DCMT insert holders securely clamp 55-degree rhombic DCMT inserts with a positive rake for finishing and profiling.

DNMG Insert Holder

DNMG insert holders securely hold 55-degree rhombic DNMG inserts, often used for versatile turning and light roughing.

External Threading Tool Holder

External threading tool holders securely hold threading inserts to create screw threads on the outer surface of a workpiece.

Face Grooving Tool Holder

Face grooving tool holders are designed to hold inserts for creating grooves on the face or end of a cylindrical workpiece.

Grooving Tool Holder

Grooving tool holders securely hold inserts for creating grooves of specific widths and depths on a workpiece's surface.

Internal Grooving Tool Holder

Internal grooving tool holders are designed to hold inserts for creating grooves within the internal diameter of a workpiece.

Internal Threading Tool Holder

Internal threading tool holders securely hold inserts to create screw threads on the inside surface of a bore or hole.

Left Hand Threading Tool Holder

Left hand threading tool holders securely hold inserts for cutting screw threads that tighten by turning counter-clockwise.

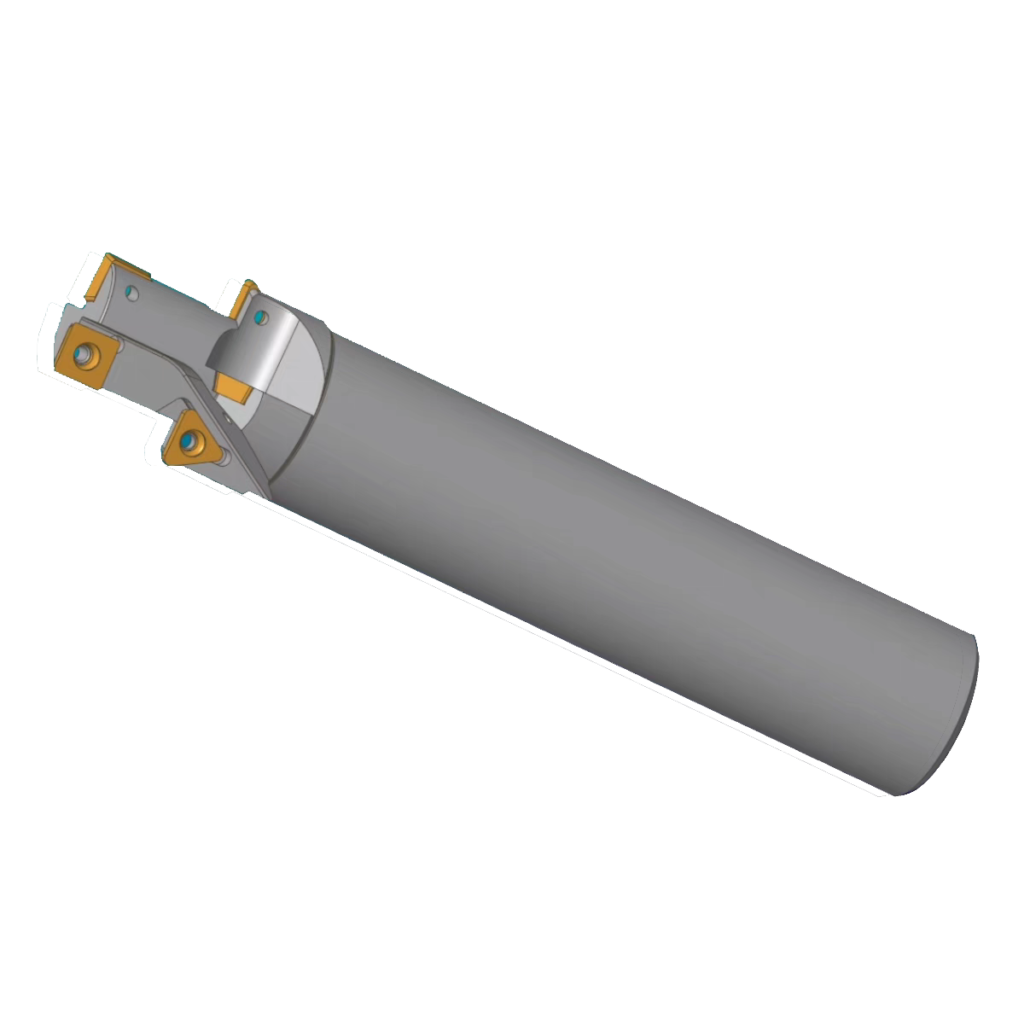

OD Turning Tool Holder

OD turning tool holders securely hold cutting inserts for machining the outer cylindrical surface of a workpiece.

Parting Tool Holder

Parting tool holders rigidly support thin blades to precisely cut off or separate a workpiece on a lathe.

SNMG Insert Tool Holder

SNMG insert tool holders securely hold SNMG square inserts, commonly used for medium to heavy-duty turning operations.

TCMT Insert Holder

TCMT insert holders securely clamp TCMT triangular inserts with a positive rake for smooth, light-to-medium turning and profiling.

Threading Tool Holder

Threading tool holders are designed to securely hold threading inserts for creating screw threads on either the internal or external surfaces of a workpiece.

TNMG Insert Holder

TNMG insert holders securely hold TNMG triangular inserts, commonly used for versatile turning operations.

VBMT Insert Holder

VBMT insert holders securely clamp VBMT V-shaped inserts with a positive rake, offering multiple cutting edges for economical turning.

VNMG Insert Holder

VNMG insert holders securely hold VNMG V-shaped inserts, often used for finishing and profiling operations with good accessibility.

WNMG Insert Holder

WNMG insert holders securely hold WNMG hexagonal inserts, offering multiple cutting edges for versatile and economical turning.

Custom Tool Holder Solutions

At our company, we understand that standard tooling doesn’t always meet the unique demands of every machining operation. That’s why we offer comprehensive custom tool holder design and manufacturing services. Our experienced engineering team and advanced manufacturing capabilities allow us to create tool holders precisely tailored to your specific requirements, ensuring optimal performance, efficiency, and precision.

Why Choose Custom Tool Holders?

- Optimized Performance: Design tool holders for specific applications and materials, maximizing cutting efficiency and tool life.

- Unique Geometries: Create tool holders with specialized shapes, angles, or features that are not available in standard options.

- Material Selection: Choose the ideal material for your application, considering factors like wear resistance, rigidity, and thermal stability.

- Specific Dimensions: Obtain tool holders with precise lengths, diameters, and other critical dimensions to fit your machinery and workpieces perfectly.

- Integration with Existing Systems: Design tool holders that seamlessly integrate with your current machine tools and setups.

- Problem Solving: Address challenging machining tasks with custom-designed solutions that overcome limitations of standard tooling.

Our Customization Capabilities

- Turning Tool Holders: Modifications to shank size, head angle, insert clamping mechanisms, and internal coolant delivery.

- Threading Tool Holders: Custom thread profiles, shank designs for specific machines, and coolant configurations.

- Cut-Off Tool Holders: Tailored blade heights, lengths, and clamping systems for specific cut-off operations.

- Grooving Tool Holders: Custom groove widths, depths, and shank designs for unique grooving applications.

- Boring Bars: Modifications to length, diameter, material, and internal coolant channels for specific bore sizes and depths.

- Specialty Tool Holders: Design and manufacture entirely new tool holder concepts based on your unique requirements.

The Customization Process

- Consultation & Inquiry: Contact our experienced sales or engineering team to discuss your specific needs and application requirements. You can use the contact form below.

- Technical Specification & Design: Provide us with detailed technical drawings, specifications, or even sketches of your desired tool holder. Our engineers can also assist with the design process if needed.

- Quotation & Lead Time: Based on your specifications, we will provide you with a detailed quotation and estimated lead time for manufacturing.

- Manufacturing & Quality Control: Once you approve the quotation, your custom tool holder will be manufactured using our state-of-the-art equipment and undergo rigorous quality control checks to ensure it meets your exact specifications.

- Delivery & Support: Your custom tool holders will be carefully packaged and shipped to your location. Our team is also available for ongoing technical support and assistance.

Frequently Asked Questions

Turning tool holders are primarily used on lathes, which are machine tools that rotate a workpiece while a cutting tool is fed against it to remove material. This process is used to create cylindrical or conical shapes, threads, grooves, and other features on a workpiece.

Key Features of a Turning Tool Holder:

- Clamping Mechanism: It features a mechanism (such as screws, wedges, or levers) to firmly grip and hold the cutting tool.

- Shank or Mounting Interface: It has a shank or a specific interface that allows it to be mounted and secured onto the lathe’s tool post or turret.

- Material: They are typically made from hardened steel or other durable materials to withstand the forces involved in machining.

- Indexable Tool Holders: These holders are designed to hold indexable cutting inserts, which can be rotated or replaced when the cutting edge becomes worn. They are widely used for their versatility and ease of use.

- Boring Bar Holders: Specifically designed to hold boring bars used for enlarging or finishing internal diameters in a workpiece.

- Cut-off Tool Holders: Used to hold thin, blade-like tools for parting off or grooving operations.

- Threading Tool Holders: Designed to securely hold threading inserts for cutting external or internal threads.

- Quick Change Tool Holders: These systems allow for very rapid tool changes, significantly reducing setup times in production environments.

Contact Us for Your Tool Holders

Please note: We are a wholesale supplier and have minimum order quantities.