In the ever-evolving world of manufacturing and machining, precision and efficiency are paramount. As industries push the boundaries of what’s possible, the demand for specialized tooling has never been greater. Enter the custom end mill – a game-changing solution that’s transforming the landscape of modern machining. From aerospace to medical devices, custom end mills are enabling manufacturers to achieve unprecedented levels of accuracy and productivity.

In this comprehensive guide, we’ll explore the world of custom end mills, delving into their applications, benefits, and the various types available, including custom carbide end mills, custom profile end mills, and custom tapered end mills. Whether you’re a seasoned machinist or a manufacturing professional looking to optimize your processes, this article will provide valuable insights into how custom end mills can elevate your machining capabilities.

Understanding Custom End Mills

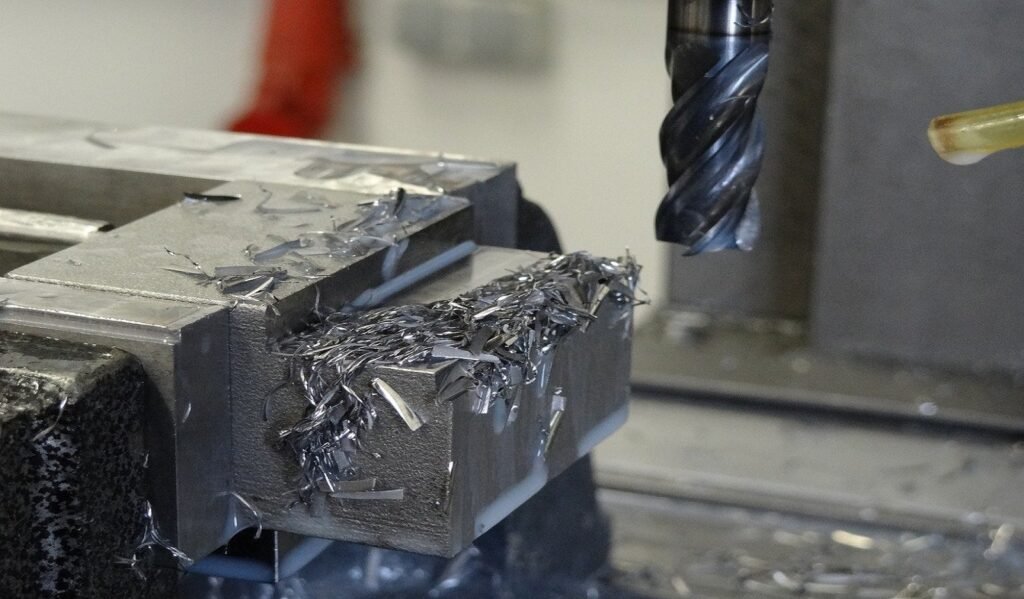

A custom end mill is a cutting tool specifically designed and manufactured to meet unique machining requirements. Unlike standard off-the-shelf end mills, custom end mills are tailored to perform specific cutting operations with maximum efficiency and precision. These specialized tools are crafted to exact specifications, taking into account factors such as material properties, cutting parameters, and desired geometries.

The Advantages of Custom End Mills

- Enhanced Precision: Custom end mills are engineered to achieve tighter tolerances and superior surface finishes, resulting in higher-quality parts.

- Improved Efficiency: By optimizing the cutting geometry for specific applications, custom end mills can significantly reduce machining time and increase productivity.

- Extended Tool Life: Custom end mills can be designed with specialized coatings and materials to withstand harsh cutting conditions, leading to longer tool life and reduced downtime.

- Cost-Effective Solution: While the initial investment may be higher, custom end mills often prove more economical in the long run by reducing cycle times, improving part quality, and minimizing tool changes.

- Unique Geometries: Custom end mills enable the creation of complex shapes and features that would be difficult or impossible to achieve with standard tooling.

Types of Custom End Mills

1. Custom Carbide End Mills

Custom carbide end mills are at the forefront of high-performance machining. Carbide, a compound of carbon and tungsten, offers exceptional hardness and wear resistance, making it ideal for demanding applications. When tailored to specific needs, custom carbide end mills can deliver outstanding results in terms of tool life, cutting speed, and surface finish.

Key benefits of custom carbide end mills

- Superior heat resistance, allowing for higher cutting speeds

- Excellent wear resistance, resulting in longer tool life

- Ability to machine hard materials with precision

- Reduced cutting forces, leading to improved part quality

Applications for custom carbide end mills span various industries, including aerospace, automotive, and die/mold manufacturing. These tools excel in machining tough materials like hardened steels, titanium alloys, and composite materials.

2. Custom Profile End Mills

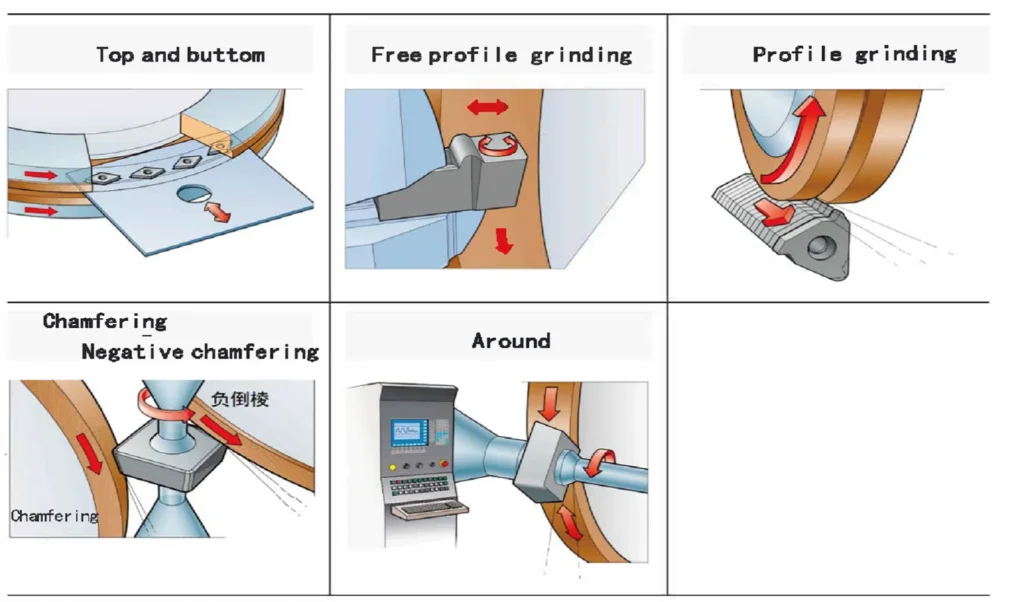

Custom profile end mills are designed to create specific contours or shapes in a single pass, eliminating the need for multiple tools or operations. These specialized end mills can significantly reduce machining time and improve part consistency, making them invaluable for high-volume production.

Advantages of custom profile end mills include:

- Reduced cycle times by combining multiple cutting operations

- Improved surface finish and dimensional accuracy

- Elimination of tool changes, leading to increased productivity

- Ability to create complex geometries efficiently

Custom profile end mills find extensive use in industries such as automotive, where they’re employed to machine engine components, transmission parts, and chassis elements. They’re also crucial in the production of medical implants, where precise, complex geometries are essential.

3. Custom Tapered End Mills

Custom tapered end mills feature a gradually decreasing diameter from the shank to the tip, allowing for the machining of angled surfaces and deep cavities. These specialized tools are particularly useful in mold making, aerospace components, and turbine blade manufacturing.

Benefits of custom tapered end mills

- Improved rigidity and reduced tool deflection in deep cavity machining

- Enhanced chip evacuation, leading to better surface finishes

- Ability to create complex 3D shapes and contours

- Reduced vibration and chatter in challenging machining operations

Custom tapered end mills are often employed in the production of turbine blades, where they excel at creating the complex, twisted geometries required for optimal aerodynamic performance. They’re also widely used in the die and mold industry for creating draft angles and tapered features.

The Custom End Mill Design Process

Creating a custom end mill involves a collaborative process between the manufacturer and the end-user. This process typically includes the following steps:

- Application Analysis: The first step involves a thorough understanding of the specific machining requirements, including material properties, desired geometries, and production volumes.

- Design Optimization: Using advanced CAD/CAM software, engineers develop an optimized tool design that meets the specified requirements while maximizing performance and tool life.

- Material Selection: Based on the application, appropriate tool materials and coatings are selected to ensure optimal performance and longevity.

- Prototyping and Testing: Before full-scale production, prototypes are manufactured and rigorously tested to validate performance and make any necessary refinements.

- Manufacturing: Once the design is finalized, the custom end mills are produced using state-of-the-art CNC grinding machines and precision measurement equipment.

- Quality Control: Each custom end mill undergoes stringent quality checks to ensure it meets the specified tolerances and performance criteria.

Maximizing the Benefits of Custom End Mills

To fully leverage the advantages of custom end mills, consider the following best practices:

- Collaborate Closely with Tool Manufacturers: Work closely with your tooling provider to ensure they fully understand your specific machining challenges and requirements.

- Optimize Cutting Parameters: Develop and fine-tune cutting parameters specifically for your custom end mills to maximize their performance and longevity.

- Implement Proper Tool Management: Establish a robust tool management system to track usage, performance, and wear patterns of your custom end mills.

- Invest in High-Quality Tool Holders: Use precision tool holders to minimize runout and ensure optimal performance of your custom end mills.

- Regular Maintenance and Reconditioning: Implement a proactive maintenance program to keep your custom end mills in peak condition and consider reconditioning services to extend their useful life.

The Future of Custom End Mills

As manufacturing technologies continue to advance, the role of custom end mills is expected to grow even further. Some emerging trends in custom end mill technology include:

- Advanced Materials: Development of new tool materials and coatings that offer even greater wear resistance and performance in extreme conditions.

- Additive Manufacturing: Integration of 3D printing technologies in the production of custom end mills, allowing for even more complex geometries and internal cooling channels.

- Smart Tools: Incorporation of sensors and IoT technologies to monitor tool wear and performance in real-time, enabling predictive maintenance and process optimization.

- Artificial Intelligence: Use of AI and machine learning algorithms to optimize tool designs based on vast amounts of performance data.

Conclusion

Custom end mills represent a significant leap forward in machining technology, offering unparalleled precision, efficiency, and versatility. From custom carbide end mills that tackle the toughest materials to custom profile end mills that streamline complex operations, these specialized tools are revolutionizing manufacturing across industries.

By embracing the power of custom end mills, manufacturers can unlock new levels of productivity, quality, and innovation. As we look to the future, the continued evolution of custom end mill technology promises to push the boundaries of what’s possible in precision machining even further.

Whether you’re looking to optimize your current processes or tackle new, challenging applications, investing in custom end mills could be the key to staying competitive in today’s fast-paced manufacturing landscape. Partner with a reputable tooling manufacturer to explore how custom end mills can transform your machining operations and drive your business forward.