The End mill is a tool for side milling and contouring with a thin insert for small and complex workpiece contours. The Face mill, on the other hand, is a tool for flat milling and smooth surface machining with a wider insert for machining larger workpiece surfaces in a single pass.

end mill introduce:

The End mill is a tool for milling operations. The End mill is available in a variety of head shapes, including ball, flat, tapered and rounded, and can be used for machining different shapes, such as flat surfaces, contours and grooving. An end mill is widely used in metal processing, mould-making, aerospace and automotive manufacturing.

Different shapes of cutter heads for different machining requirements:

- Ball head for curved and round surfaces

2. flat head for flat surfaces and contouring

3. tapered head for beveling and chamfering etc

Effect of a number of edges on machining:

The number of edges refers to the number of inserts in the End mill, which are usually available with different numbers of edges such as single, double, triple, quadruple and six edges. Generally speaking, the higher the number of edges, the more efficient the machining process, as the load on each insert is less and the cutting forces are more stable. In addition, an End mill with a higher number of edges reduces vibration and noise during machining and improves machining accuracy. However, the higher the number of edges, the thinner the inserts of the End mill and the less strong they are, making them prone to breakage or wear.

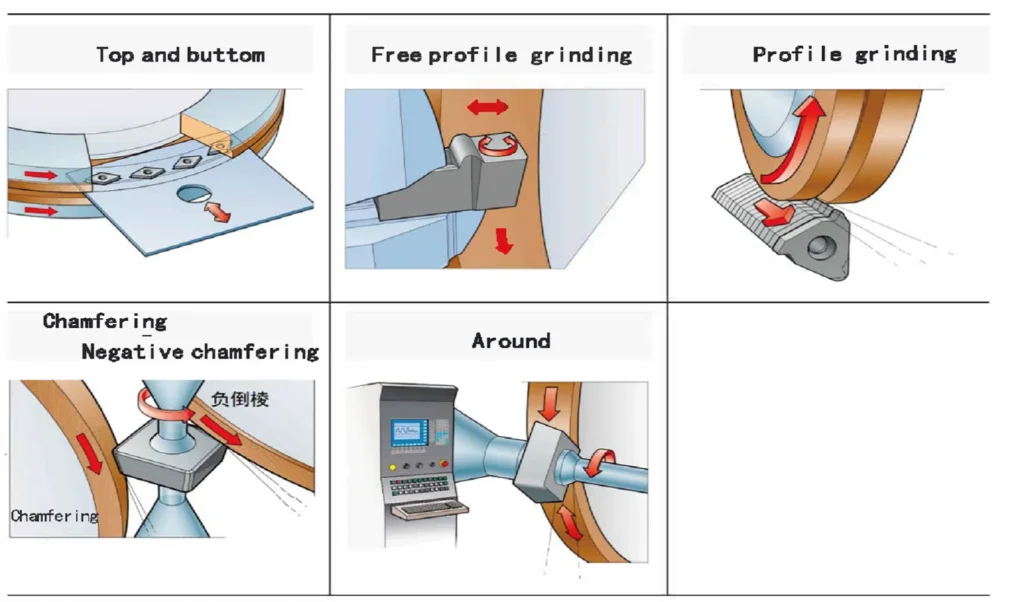

Effect of edge shape on machining:

The common blade shapes are straight, spiral, comb and blade pattern. Different blade shapes are suitable for different machining situations and have different machining effects. For example, spiral tooth inserts reduce vibration and impact during machining and are suitable for machining hard materials; patterned inserts are suitable for machining complex contours and curves; straight tooth inserts are suitable for machining hard materials and flat surfaces, etc.

Effect of edge angle on machining:

The angle of the cutting-edge shape affects the machining results. For example, the higher the cutting angle, the faster the machining speed but also the faster the insert wear. The greater the angle behind the cutting edge, the greater the machining accuracy, but the corresponding reduction in machining speed.

Face mill introduce:

The face mill is a metal cutting tool used for flat milling and bright surface machining. It usually consists of a tool holder, a tool head and an insert. The tool holder is the main part of the Face mill and is connected to the machine spindle to transmit rotational power. The head is a rotatable part mounted on the shank which, together with the insert, forms the cutting part of the tool. The inserts are usually of interchangeable type, allowing for easy replacement and maintenance.

The Face mill has a wider blade, which allows a larger surface area to be machined in one pass, increasing machining efficiency. The number of inserts is generally high and can be adjusted to suit your needs. There are many different blade shapes, including flat blades, spiral blades and toothed blades. Each insert shape has its own applicable machining range and machining results. For example, flat surface machining is suitable for flat surfaces and contouring, while smooth surface machining requires a smoother insert surface and a smaller depth of cut.

Different between end mill and face mill:

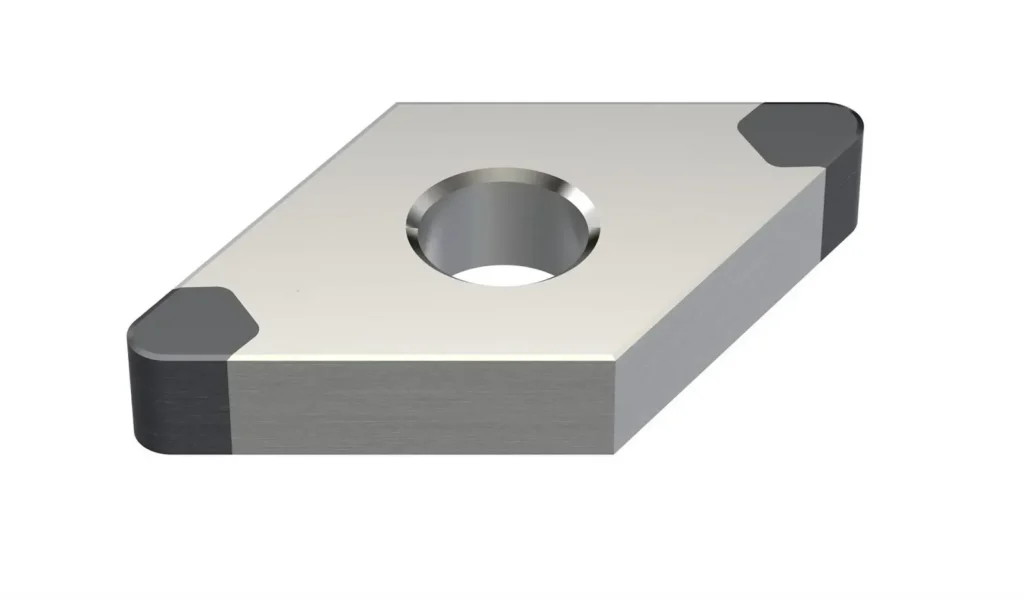

The End mill is a tool for side milling and contouring, which usually consists of a shank, a head and an insert. the inserts of the End mill are thin and have a relatively small cutting area, making them suitable for small and complex workpiece contours. there are many different insert shapes, such as flat, ball, angular and chamfered, each of which has its own range of applications and results. Each shape has its own range of applications and results.

Face mill is a tool used for flat milling and smooth surface machining, it usually consists of a shank, a head and an insert. face mill inserts are wider, allowing a larger surface area to be machined in one pass, increasing machining efficiency. face mill inserts are generally larger in number and can be adjusted as required. There are many different blade shapes, including flat blades, spiral blades and toothed blades, each of which has its own range of applications and machining results.