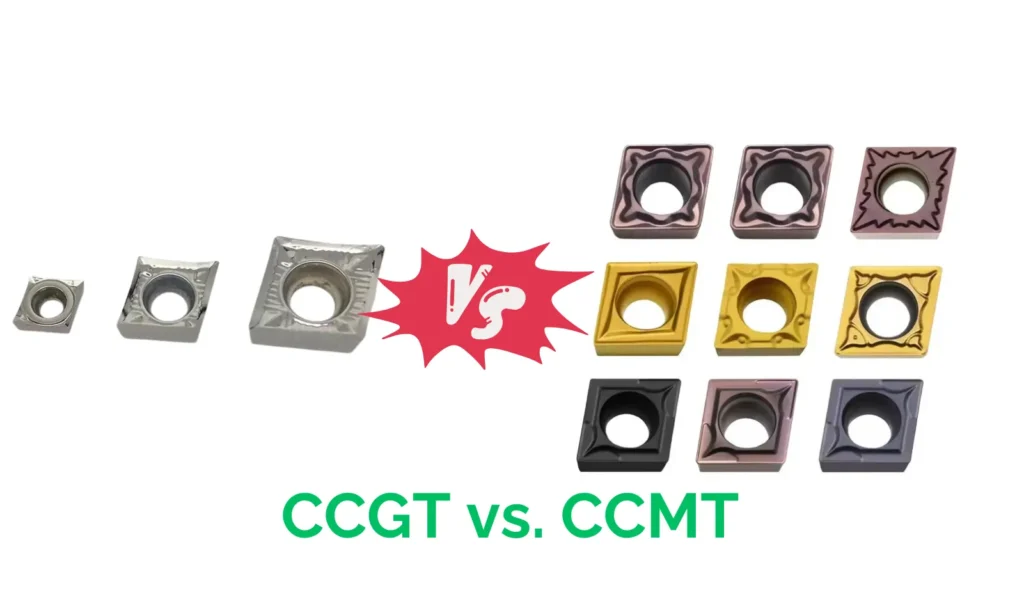

CCMT vs. CCGT Turning Inserts: Key Differences & Size Chart Guide

In CNC turning, choosing the right insert is critical for precision and tool life. A common confusion among machinists is the difference between CCMT vs. CCGT inserts. They look similar and fit the same tool holders, but they perform very different tasks. This guide explains the technical differences, answers “What is a Ccmt insert?” and “What is a CCGT insert?”, and provides a detailed Ccgt vs ccmt size chart for reference.

Quick Summary: The Core Difference

The main difference lies in manufacturing process and edge preparation:

- CCMT (Molded): Has a honed (rounded) edge for strength. Best for Steel, Cast Iron, and roughing applications.

- CCGT (Ground): Has a razor-sharp, ground edge. Best for Aluminum, Non-Ferrous Metals, and high-precision finishing.

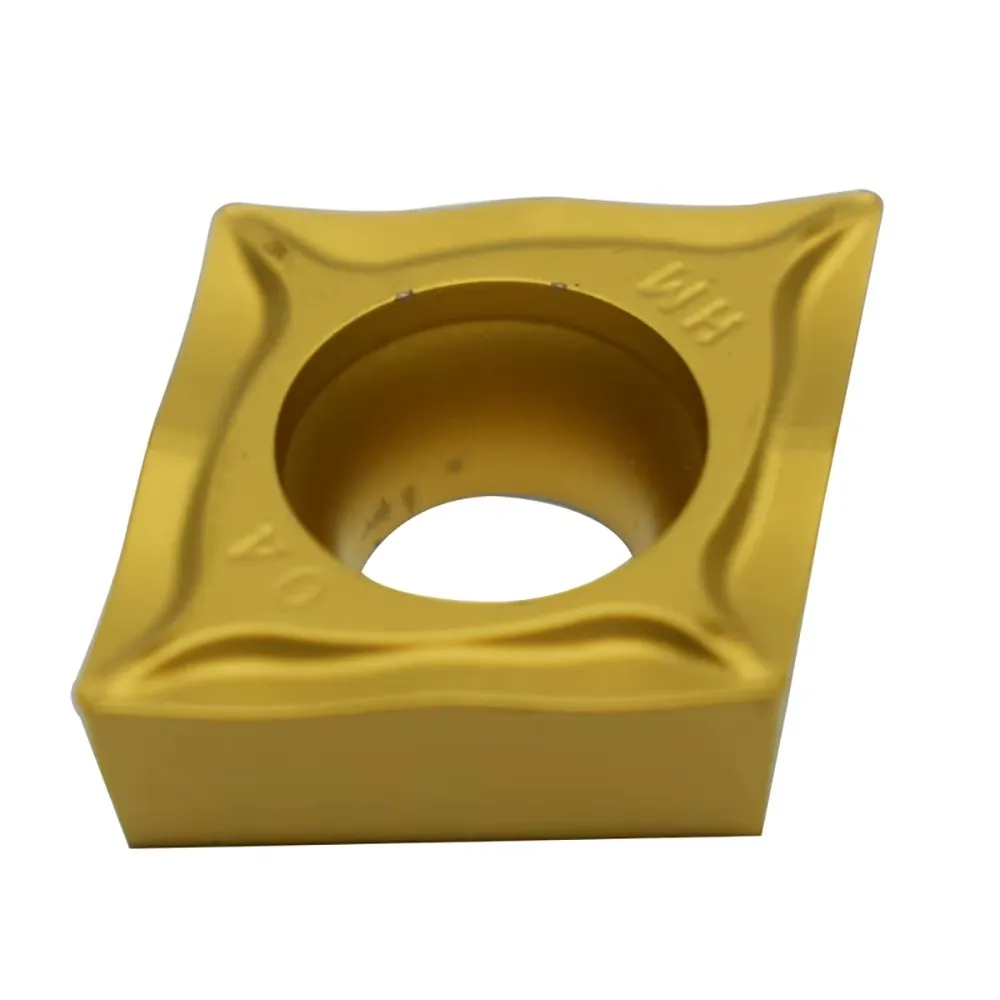

What is a CCMT Insert?

CCMT inserts are the industry standard for general-purpose turning. According to the ISO code system:

- C: 80° Diamond Shape

- C: 7° Relief Angle (Positive)

- M: M-Class Tolerance (Molded/Sintered)

- T: Chipbreaker and countersink hole

Key Characteristic:

The cutting edge of a CCMT insert undergoes “honing” (edge rounding). This microscopic radius strengthens the edge, preventing it from chipping when cutting hard materials like Carbon Steel (P) or Stainless Steel (M).

- Best For: Medium to heavy roughing, interrupted cuts, and processing steels.

What is a CCGT Insert?

CCGT inserts are designed for precision and low cutting pressure. The key identifier in the ISO code is the third letter:

- G: G-Class Tolerance (Ground)

Unlike the molded CCMT, the CCGT insert is fully ground on its periphery and faces. It features an “Up-Sharp” edge (no honing). This razor-sharp geometry shears through material cleanly rather than pushing it, generating very little heat and cutting force.

- Best For: Aluminum (N), Copper, Plastics, and super-finishing on steels where low cutting pressure is required (e.g., thin-walled parts).

Comparison Table: CCMT vs. CCGT

For a quick decision, refer to this feature comparison.

| Feature | CCMT Insert | CCGT Insert |

| Manufacturing | Molded (Sintered) | Precision Ground |

| Edge Prep | Honed / Chamfered (Strong) | Up-Sharp (Razor Edge) |

| ISO Tolerance | Class M (Standard) | Class G (High Precision) |

| Cutting Force | High | Very Low |

| Coating | Usually Thick CVD/PVD | Polished (Uncoated) or Thin DLC |

| Primary Material | Steel, Stainless, Cast Iron | Aluminum, Brass, Plastic |

| Cost | Economy | Premium |

CCGT vs. cCMT Size Chart

A frequently asked question is about the physical dimensions. Yes, CCMT and CCGT inserts are geometrically compatible. If you have an SCLCR turning holder, it can hold both insert types.

However, the tolerance (accuracy) differs significantly.

ISO Standard Dimensions (Interchangeable)

| Insert Size Code | I.C. (Inscribed Circle) | Thickness (S) | Hole Diameter (d) | Typical Holder |

| CC__ 0602__ | 6.350 mm (1/4″) | 2.38 mm (3/32″) | 2.8 mm | SCLCR 0808… |

| CC__ 09T3__ | 9.525 mm (3/8″) | 3.97 mm (5/32″) | 4.4 mm | SCLCR 1616… |

| CC__ 1204__ | 12.70 mm (1/2″) | 4.76 mm (3/16″) | 5.5 mm | SCLCR 2020… |

Tolerance Gap (Why “G” Class costs more)

The Ccgt vs ccmt size chart isn’t just about size—it’s about precision consistency.

| Dimension | CCMT (Class M Tolerance) | CCGT (Class G Tolerance) |

| Tip Height (m) | ±0.08mm | ±0.025mm |

| I.C. Diameter | ±0.05mm | ±0.025mm |

| Thickness | ±0.13mm | ±0.13mm |

Tech Note: Because of the tighter tolerance on the CCGT, when you switch from a CCMT to a CCGT insert, you may need to adjust your CNC machine’s wear offset (X-axis) to maintain part dimensions.