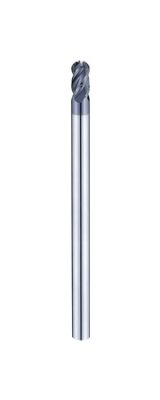

ball nose end mill

Are you tired of subpar ball nose end mills that compromise your machining precision? Do you struggle with inconsistent quality, long lead times, and budget-busting prices? It’s time to revolutionize your approach to precision cutting tools.

Imagine a world where your CNC machines hum with efficiency, producing flawlessly contoured surfaces and intricate 3D shapes. Picture your production line running smoothly, free from the headaches of tool breakage and premature wear. Envision your bottom line soaring as you reduce tooling costs and boost productivity.

This isn’t a pipe dream. It’s the reality our customers experience every day with our premium ball nose end mills.

At ONMY TOOLINGS, we’re not just another tooling supplier. We’re a cutting-edge manufacturing powerhouse with over a decade of experience in crafting the finest carbide ball nose end mills on the market. Our state-of-the-art factory isn’t just a production facility – it’s an innovation hub where precision meets passion.

| Custom size: 4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm,customized size | |||

| Advantages: High Precision,Good Surface & Performace | |||

| Material: | YG10X /MH10FS&UH8(China)/K44 & K40 (German)/K44UF&K88UF(Cobalt collar) | ||

| Material: | Tungsten Carbide | ||

| HRC: | 45/55/58/60/65 | ||

| Product Type: | Customized solid carbide endmills according to customer requirements | ||

| Coating: | Altin, Tialn, Tisin, Tin, DLC,Nano, Diamond | ||

| Helix Angle: | 10degree,15degree,25degree,35degree,45degree,55degree | ||

| Machining machine: | Imported Australian Anka machines and German Walther precision manufacturing | ||

| Suitable For: | Steel, Stainless Steel, Die Steel, Mould Steel, Carbon Steel, Cast Iron, Copper, etc. | ||

Ball Nose End Mills gallery

Step into the world of unparalleled cutting precision with ONMY TOOLINGS’s extraordinary lineup of bull nose end mills. From micro-machining marvels to heavy-duty workhorses, our diverse range is designed to conquer every milling challenge you face.

What sets us apart?

1. Unrivaled Research & Development

Our team of brilliant engineers and metallurgists are constantly pushing the boundaries of ball nose end mill technology. From our extra long ball nose end mills that reach deep into complex cavities to our game-changing indexable ball nose end mill designs, we’re always one step ahead of the competition.

2. Comprehensive Range

Whether you need a delicate single flute ball end mill for intricate detail work or a robust 4 flute ball nose end mill for high-speed roughing, we’ve got you covered. Our product line includes:

3. Factory-Direct Advantage

By cutting out the middlemen, we deliver factory-fresh tools directly to your shop floor. This means unbeatable prices without sacrificing an ounce of quality.

4. Lightning-Fast Delivery

In the fast-paced world of manufacturing, time is money. Our streamlined production and logistics ensure your tools arrive when you need them, not weeks later.

5. Rigorous Quality Control

Every carbide ball nose end mill that leaves our factory undergoes meticulous inspection. We’re proud to be ISO 9001:2015 certified, ensuring consistent world-class quality in every tool we produce.

Imagine the impact on your operations

- Slashing cycle times with tools that cut faster and last longer

- Achieving mirror-like surface finishes that your customers rave about

- Reducing scrap rates and rework, saving valuable materials and man-hours

- Tackling complex 3D contours with ease, opening up new business opportunities

- Boosting your bottom line with tools that maximize productivity and minimize downtime

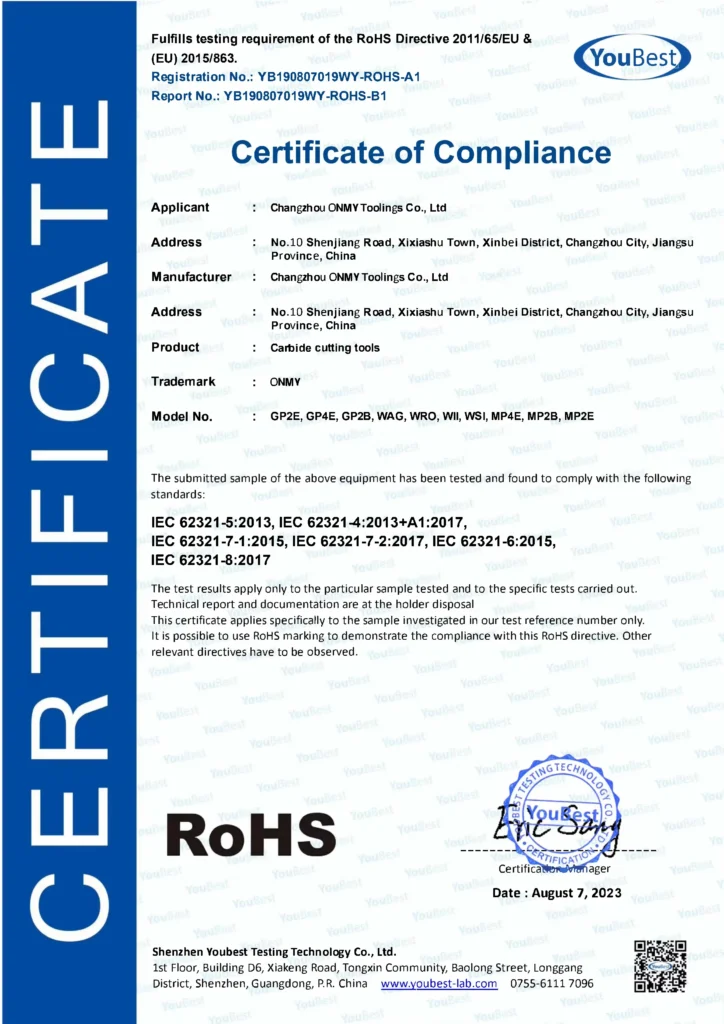

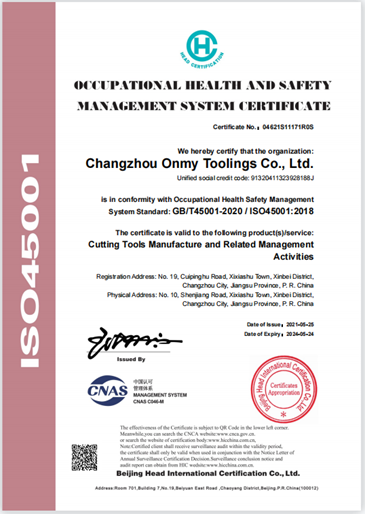

Factory Certification

These certifications aren’t just fancy badges – they’re your guarantee of consistent, top-tier quality in every tool we produce. Our quality control process includes 100% inspection of critical dimensions and advanced wear resistance testing to ensure each tool meets our exacting standards.

Our Journey to Excellence

Our story began in a small workshop with a big dream: to create the world’s finest bull nose end mills. Today, we operate a state-of-the-art 50,000 sq ft facility equipped with the latest in CNC grinding technology and advanced coating systems. But our true strength lies in our team of passionate engineers and skilled craftsmen who pour their expertise into every tool we produce.

Why settle for off-the-shelf solutions when you can have custom end mills tailored to your specific needs? Our in-house research and development team is constantly pushing the boundaries of what’s possible in machining technology. We collaborate with leading universities and industry partners to stay at the forefront of material science and cutting tool design.

Don't just take our word for it. Here's what our satisfied customers have to say:

My Happy Client!

Get Your Custom Quote Now!

P.S. Did we mention we offer bulk discounts? The more you order, the more you save!

- Explore our range: Browse our comprehensive catalog of ball nose end mills, featuring detailed specifications and application recommendations.

- Request a custom quote: Our experts will analyze your specific needs and provide a tailored solution that maximizes performance and value.

- Try risk-free: Take advantage of our 30-day satisfaction guarantee. Put our tools to the test in your own operations and see the difference for yourself.

- oin the innovation: Become a part of our collaborative R&D process. Your feedback shapes the future of our tools, ensuring they evolve with your needs.