End Mill vs Drill Bit: Mastering Machining Tool Selection

In the world of machining and woodworking, two tools stand out as essential workhorses: end mill VS drill bit. While they may seem similar at first glance, these cutting tools have distinct differences in design, function, and application. Understanding these differences is crucial for anyone involved in metalworking, woodworking, or CNC machining. This comprehensive guide will delve into the intricacies of end mills and drill bits, helping you make informed decisions for your projects.

1. Introduction

End mill vs drill bit are both rotary cutting tools used in various manufacturing processes. However, their designs and primary functions set them apart. Drill bits are specialized for creating holes, while end mills are versatile cutters capable of a wide range of operations, including side cutting, slotting, and profiling.

As we explore these tools, we’ll uncover their unique characteristics, applications, and the critical factors that determine when to use one over the other. Whether you’re a seasoned machinist or a DIY enthusiast, this knowledge will empower you to achieve better results and extend the life of your tools.

2. Drill Bits: An In-Depth Look

Definition and Primary Function

A drill bit is a cutting tool designed specifically for creating cylindrical holes. Its primary function is to remove material from the workpiece by rotating and applying pressure along its axis. The key feature of a drill bit is its ability to create accurate, concentric holes efficiently.

Drill Bit Anatomy

To understand how drill bits work, it’s essential to familiarize yourself with their anatomy:

- Point: The sharp tip that initiates the cut

- Lips: The cutting edges that remove material

- Flutes: Spiral grooves that channel chips away from the cutting area

- Margin: The narrow strip behind the cutting edge that stabilizes the bit

- Shank: The part of the bit that is held in the drill chuck

Types of Drill Bits

Drill bits come in various types, each designed for specific materials and applications. Let’s explore some common categories:

Metal Working Drill Bits:

- Indexable Bit: Features replaceable carbide inserts for extended life and versatility.

- Ejector Bit: Designed for deep-hole drilling, using high-pressure coolant to remove chips.

- Spade Drill Bit: Flat-bottomed bit for large diameter holes, often used in CNC machines.

- U-Drill: A specialized drill with internal coolant channels for efficient chip evacuation.

- Top Replacement Drill: Features a replaceable cutting tip, combining economy with performance.

Woodworking Drill Bits:

- Flat Bit: Also known as spade bits, these create rough holes quickly in wood.

- Auger Bit: Long bits with a screw tip for deep, clean holes in wood.

- Dowel Bit: Designed for creating precise holes for wooden dowels.

Drill Bit Materials

The material of a drill bit significantly affects its performance and lifespan. Common materials include:

- High-Speed Steel (HSS): Versatile and economical, suitable for general-purpose drilling. HSS drill bits are commonly used for drilling holes in wood, plastic, and soft metals like aluminum and copper, making them a great choice for home repairs and carpentry projects. For example, they easily create precise holes when building furniture or installing wall hangings. Power Tool Integration: HSS drill bits are a perfect match for various power tools, such as cordless drills and benchtop drill presses, allowing users to drill efficiently with low-powered equipment without worrying about overheating.

- Cobalt Steel: More heat-resistant than HSS, ideal for harder materials.

- Carbide: Extremely hard and durable, used for drilling abrasive materials or high-production environments.

- Diamond-tipped: For drilling extremely hard materials like ceramics or glass.

- End Mills: Understanding the Versatile Cutter

Definition and Primary Function

An end mill is a type of milling cutter, a tool used in industrial milling applications. Unlike drill bits, end mills are designed to cut in multiple directions – axially, radially, and in some cases, both simultaneously. This versatility allows end mills to perform various operations such as side cutting, slotting, profiling, and even drilling in some cases.

3. End Mill Anatomy

Understanding the anatomy of an end mill is crucial for proper selection and use:

- Shank: The part of the tool held by the machine

- Flutes: Grooves that run along the cutting edge, facilitating chip removal

- Cutting Edge: The sharp edge that performs the actual cutting

- End Cutting Edge: Allows the tool to plunge into the material

- Helix Angle: The angle of the flutes, affecting chip evacuation and cutting performance

Types of End Mills

End mills come in various types, each designed for specific applications:

- Square End Mills: Versatile tools for general-purpose milling

- Ball Nose End Mills: Ideal for 3D contouring and finishing

- Corner Radius End Mills: Combine features of square and ball nose mills

- Tapered End Mills: Used for creating angled surfaces or drafts

- Roughing End Mills: Designed for rapid material removal

End Mill Materials

Like drill bits, end mills are made from various materials to suit different applications:

- High-Speed Steel (HSS): Economical choice for softer materials

- Cobalt HSS: Improved heat resistance for tougher materials

- Carbide: Superior hardness and wear resistance for high-speed machining

- Ceramic: For high-temperature applications and hard materials

4. Key Differences: End Mill vs Drill Bit

Design and Cutting Edge Differences

The fundamental difference between drill bits and end mills lies in their design and cutting edges:

Drill Bits:

- Designed primarily for axial cutting (along their length)

- Cutting edges are located at the tip

- Flutes are optimized for chip evacuation during drilling

End Mills:

- Designed for both axial and radial cutting

- Cutting edges along the sides and often at the end

- Flutes balanced for chip evacuation and cutting performance

Functionality and Application Differences

The design differences lead to distinct functionalities:

Drill Bits:

- Specialized for creating holes quickly and efficiently

- Limited to axial movement

- Typically produce cylindrical holes

End Mills:

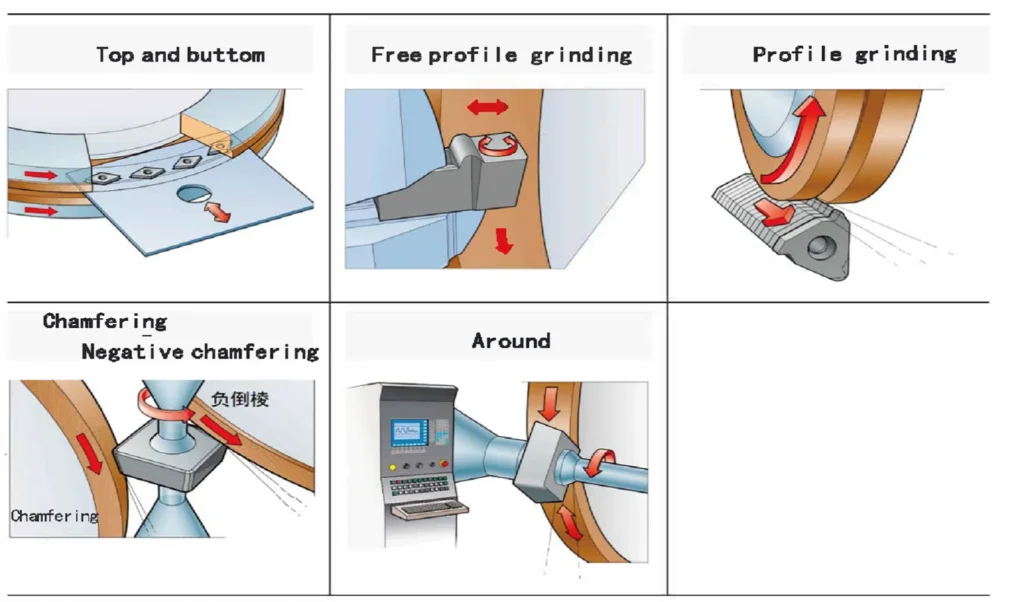

- Versatile tools capable of various cutting operations

- Can move axially, radially, or in complex paths

- Can produce a wide range of shapes and profiles

Holding Mechanisms

The way these tools are held in the machine also differs:

Drill Bits:

- Typically held in a drill chuck

- Chuck can accommodate various diameters

- Designed to handle axial forces

End Mills:

- Held in collets or specialized tool holders

- Require precise concentricity

- Must withstand both axial and radial forces

5. Applications and Best Practices

When to Use Drill Bits

Drill bits are the go-to choice when:

- Creating precise, cylindrical holes is the primary goal

- Rapid hole creation is required

- Working with a hand-held drill or drill press

- Drilling deep holes in materials like wood or metal

Best practices for drill bits:

- Use the correct bit for the material being drilled

- Maintain proper speed and feed rates

- Apply cutting fluid when appropriate

- Regularly sharpen or replace dull bits

When to Use End Mills

End mills are preferred when:

- Complex shapes or profiles are needed

- Side cutting or slotting is required

- Working with CNC machines or milling machines

- Creating non-cylindrical holes or pockets

Best practices for end mills:

- Choose the appropriate number of flutes for the material and operation

- Use climb milling when possible for better surface finish

- Maintain proper chip load to prevent tool breakage

- Employ appropriate cooling and lubrication strategies

Safety Considerations

Regardless of whether you’re using drill bits or end mills, safety should always be a top priority:

- Wear appropriate personal protective equipment (PPE)

- Secure workpieces properly

- Never exceed recommended speeds for the tool

- Keep work areas clean and free of debris

6. Conclusion

Understanding the differences between end mills and drill bits is crucial for anyone involved in machining or woodworking. While drill bits excel at creating precise, cylindrical holes quickly and efficiently, end mills offer versatility for a wide range of cutting operations.

By choosing the right tool for the job and following best practices, you can achieve better results, improve efficiency, and extend the life of your tools. Remember that the key to success in any machining operation lies not just in the quality of your tools, but in your knowledge of how to use them effectively.

Whether you’re working on a small DIY project or managing a large-scale manufacturing operation, the principles outlined in this guide will help you make informed decisions about tool selection and usage. As technology advances and new tools emerge, staying informed and adaptable will ensure your continued success in the ever-evolving world of machining and woodworking.