What are the best drill bits for metal? (The 2026 Industrial Guide)

In the unforgiving world of industrial machining, the true cost of a drill bit is defined not by its retail price, but by the catastrophic expenses of tool failure—ranging from work-hardened surfaces and snapped bits to the irreversible scrapping of high-value workpieces. Answering the pivotal question, “what are the best drill bits for metal?”, demands a professional engineering approach that prioritizes a core philosophy: the perfect hole is a result of precisely matching tool metallurgy with the specific chemistry and hardness of your workpiece. To help you navigate the vast array of options, the following executive summary identifies the best type of drill bit for metal based on your operational level, ensuring you select the best bit for drilling metal to maximize both precision and tool longevity.

Executive Summary: The Best Drill Bit for Metal by User Category

| User Level | Recommended Substrate | Best For… | Key Advantage |

| DIY / Hobbyist | TiN-Coated HSS | Aluminum, Plastics, Mild Steel | Cost-effective versatility and surface lubricity. |

| Professional / MRO | M35 Cobalt (5%) | Stainless Steel, High-Tensile Alloys | High “Red Hardness” and superior ROI per hole. |

| Industrial / CNC | Solid Carbide | Hardened Steel, High-Volume Production | Maximum RPM capacity and extreme wear resistance. |

2. Metallurgy: The Science of Substrates

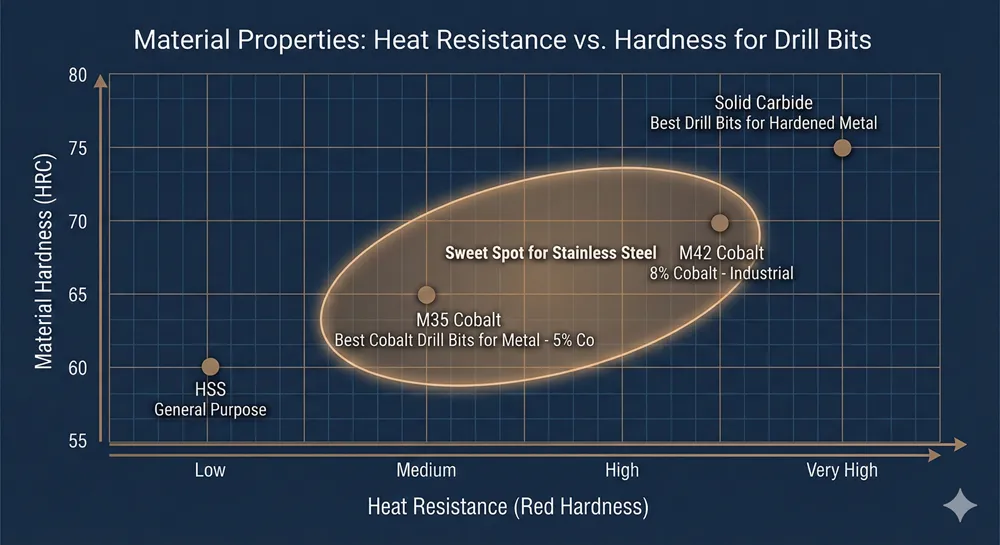

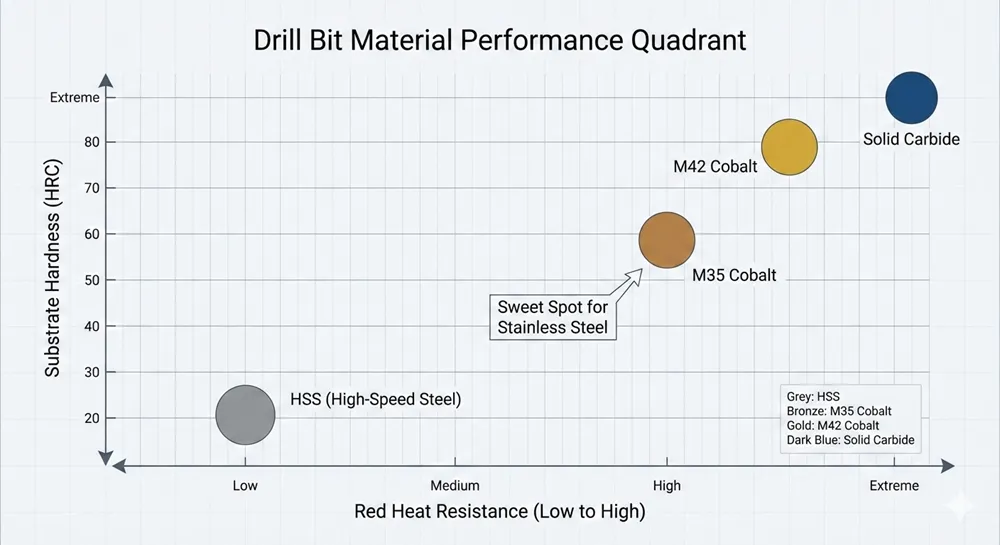

The performance of any cutting tool is fundamentally dictated by its ability to maintain “Red Hardness”—the metallurgical property that allows a material to retain its hardness even when friction generates temperatures that would cause standard steel to soften. When evaluating the best type of drill bit for metal, the choice of substrate represents the most significant investment in tool longevity.

2.1 High-Speed Steel (HSS): The Industry Baseline

High-Speed Steel (HSS) has been the standard for over a century, offering excellent toughness and resistance to breakage. While it remains a reliable choice for soft materials like aluminum, plastics, and low-carbon mild steel, it is frequently not the best bit for drilling metal when dealing with modern, high-strength alloys. The primary limitation of HSS is its thermal threshold; once the cutting edge exceeds approximately 500°C, the material undergoes a tempering effect, leading to rapid edge dulling and “burnishing” of the workpiece.

2.2 The Cobalt Evolution: M35 vs. M42

To overcome the thermal limitations of standard HSS, cobalt is added to the alloy matrix. Cobalt does not significantly increase the hardness of the bit at room temperature; rather, it acts as a binder that prevents the steel from softening under extreme heat.

- M35 Cobalt (5% Cobalt): Known as the “Workhorse of the Machine Shop,” M35 is widely regarded as the best cobalt drill bits for metal in general maintenance and repair operations (MRO). It offers a perfect equilibrium between hardness and toughness, making it the best drill bits for steel and 300-series stainless steel (like 304 and 316), where constant feed pressure generates significant heat.

- M42 Cobalt (8% Cobalt): Engineered for high-stress environments, M42 provides a higher red-hardness threshold than M35. It is the preferred choice for aerospace-grade alloys, titanium, and high-nickel superalloys. However, the increased cobalt content makes the bit slightly more brittle, requiring a stable setup to prevent snapping.

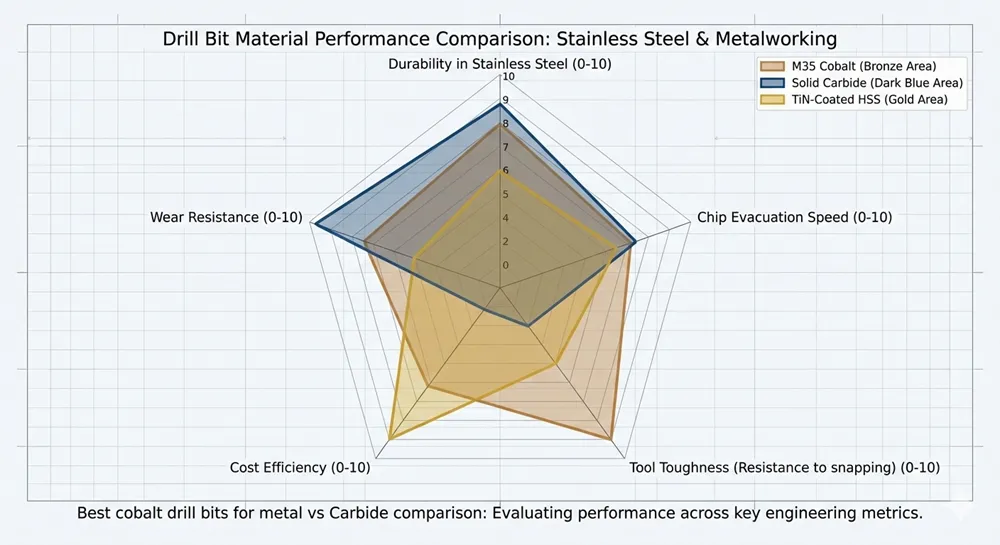

2.3 Solid Carbide: The Pinnacle of Hardness

When productivity is measured by cycle time and tool life in high-volume production, Solid Carbide stands alone. Composed of tungsten carbide particles bonded with cobalt, it is the best drill bits for hardened metal exceeding 45 HRC. Unlike steel-based bits, carbide is extremely rigid and can operate at cutting speeds three to five times higher than HSS. However, because carbide has low impact resistance (toughness), it must be used in rigid machine spindles; using it in a handheld drill will almost certainly result in catastrophic tool fracture.

Table 1: Substrate Performance Comparison

| Substrate Material | Hardness (HRC) | Red Hardness (Thermal Limit) | Toughness (Impact Resistance) | Relative Cost | Best Application |

| Standard HSS | 62 – 64 | Low (~500°C) | Highest | $ | Aluminum, Mild Steel, Wood |

| M35 Cobalt (5%) | 65 – 67 | High (~620°C) | High | $$ | Best for Stainless Steel |

| M42 Cobalt (8%) | 67 – 69 | Very High (~680°C) | Moderate | $$$ | Titanium, Aerospace Alloys |

| Solid Carbide | 75+ | Superior (>1000°C) | Low (Brittle) | $$$$ | Best for Hardened Steel |

Cutting Geometry: Point Angles and Flute Dynamics

While the substrate determines the material’s survival, the geometry of the tool determines the efficiency of the cut. In industrial machining, geometry is the “interface” between the machine’s power and the workpiece’s resistance. Selecting the best type of drill bit for metal requires a nuanced understanding of how point angles and flute designs manage thrust force and chip evacuation.

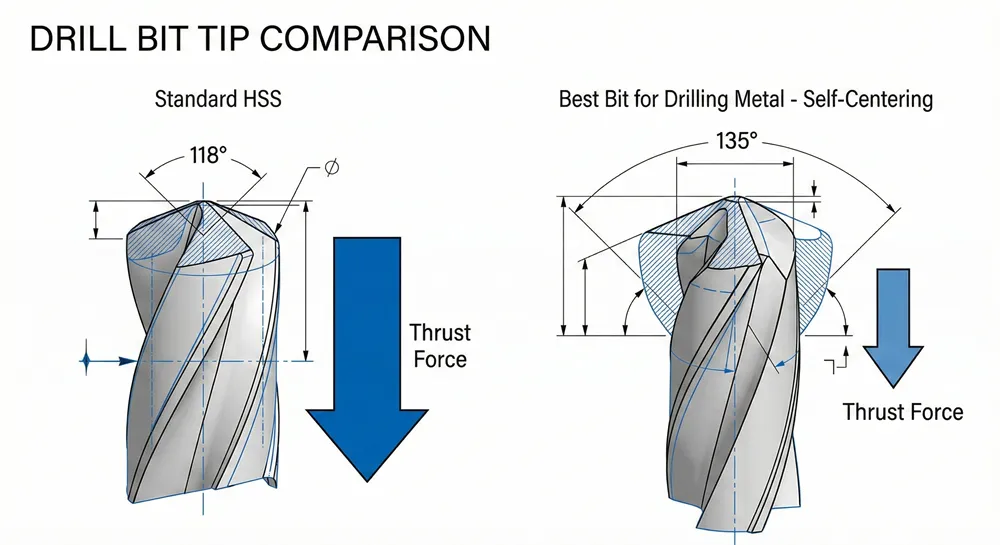

3.1 118° vs. 135° Point Angles

The point angle is the angle formed at the tip of the drill bit. Historically, 118° has been the standard for general-purpose drilling. However, for serious metalwork, the distinction is critical:

- 118° Point Angle: Best suited for soft metals like aluminum and mild steel. The sharper point is easier to sharpen manually but lacks the strength required for high-tensile alloys.

- 135° Point Angle: This is the professional choice for the best drill bits for steel and stainless steel. The flatter point puts more of the cutting edge in contact with the material sooner and allows for a shorter “chisel edge,” which significantly reduces the pressure required to begin the cut.

3.2 The Split Point Advantage: Eliminating “Walking”

Perhaps the most important geometric feature of the best bit for drilling metal is the Split Point (often called a self-centering point).

Traditional bits have a flat chisel edge at the very tip that doesn’t actually cut—it smears the metal until the cutting lips can engage. This causes the bit to “walk” or skid across the surface. A 135-degree split point is ground with two additional cutting edges on the chisel, allowing it to “bite” the metal instantly. This eliminates the absolute necessity of a center punch and ensures higher positional accuracy.

3.3 Web Design and Web Thinning

The “Web” is the solid metal core that runs up the center of the drill bit between the flutes. It provides the structural rigidity that prevents the bit from snapping under torque.

- The Paradox: A thick web makes the bit stronger, but it also increases the “chisel edge” size, making it harder to penetrate the metal.

- The Solution: Industrial-grade bits often feature “Web Thinning” at the point. This maintains a thick, strong core for the body of the bit while reducing the resistance at the tip, making it the best type of drill bit for metal for high-feed applications.

3.4 Flute Geometry: Standard vs. Parabolic

Flutes are the spiral grooves responsible for pulling chips out of the hole and allowing coolant to reach the cutting edge.

- Standard Flutes: Ideal for shallow holes (less than 3x the drill diameter).

- Parabolic Flutes: These feature a wider, more open spiral. For deep-hole drilling (4xD or greater), parabolic geometry is essential. It prevents “chip packing”—where hot metal curls get stuck in the flutes—which is the primary cause of bit breakage in deep-hole metalworking.

Table 2: Geometry Selection for Metalworking Success

| Feature | 118° Standard Point | 135° Split Point | Parabolic Flute Design |

| Material Hardness | Soft to Medium | High-Tensile / Hard | All (Deep Hole Focus) |

| Thrust Force | High (Requires Pressure) | Low (Easier Penetration) | Moderate |

| Self-Centering | No (Tends to “Walk”) | Yes (Self-Centering) | Varies by Point Design |

| Chip Evacuation | Standard | High Efficiency | Superior (Prevents Clogging) |

| Recommended Use | General DIY / Aluminum | Professional Machining | Deep Holes / Production |

4. The Stainless Steel Challenge: Overcoming Work Hardening

Stainless steel—specifically the austenitic 300-series (304 and 316)—is widely regarded as the “nemesis” of the amateur machinist. Unlike carbon steel, stainless steel possesses a unique set of metallurgical characteristics that can destroy a drill bit in seconds if the operator is unprepared. Understanding these challenges is the first step in identifying the best drill bits for stainless steel.

4.1 The Mechanism of Work Hardening

The primary difficulty with stainless steel is its high rate of work hardening. When the material is subjected to mechanical stress (like the friction of a drill bit), its molecular structure rearranges, becoming significantly harder than its original state.

If a drill bit “dwells” or rubs against the surface without actively cutting, it creates a localized zone of extreme hardness. This zone often becomes harder than the drill bit itself, leading to a “glazed” surface that is virtually impenetrable. To prevent this, the best drill bits for stainless steel must be sharp enough to bite into the metal immediately and maintain a constant, aggressive feed.

4.2 Why Cobalt is the Best Drill Bit Material for Stainless Steel

While Titanium Nitride (TiN) coated HSS bits are often marketed for metal, they are frequently insufficient for stainless applications. Cobalt (M35 or M42) is the definitive best drill bit material for stainless steel for two reasons:

- Thermal Conductivity: Stainless steel has poor thermal conductivity. Instead of the heat being carried away by the chips, it stays concentrated at the cutting edge. Cobalt bits can withstand this concentrated heat without losing their edge.

- Edge Strength: The 5% to 8% cobalt content provides the necessary rigidity to maintain a sharp 135° split point under high feed pressures, which is essential to keep the bit cutting through the work-hardened layer.

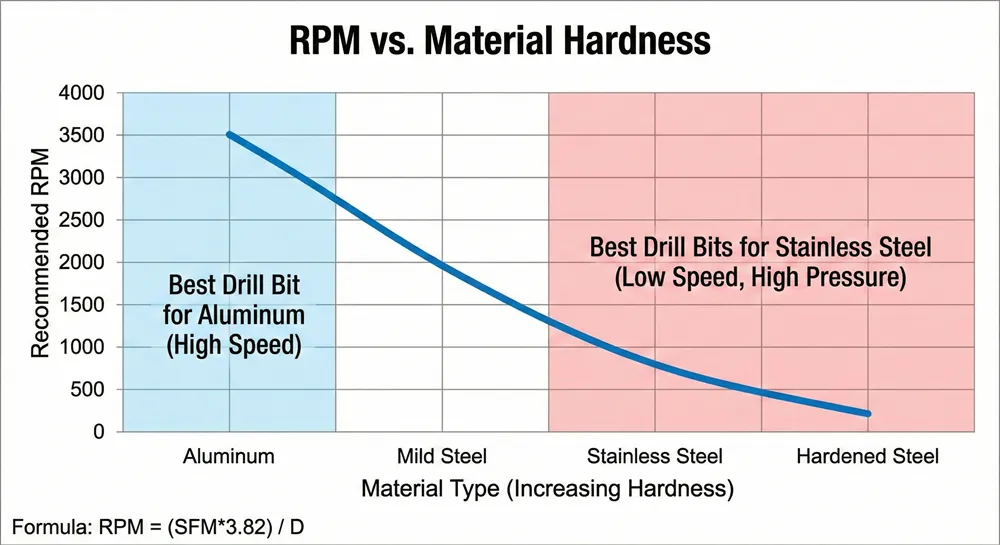

4.3 Machinist Protocol: Managing the “Feed and Speed”

Selecting the best drill bits for stainless steel is only half the battle; the other half is operational discipline. Professional machinists follow the “Slow and Heavy” rule:

- Slow RPM: High speeds generate friction, which triggers work hardening. You must reduce your RPM by 50-60% compared to drilling mild steel.

- Heavy Feed Pressure: You must apply enough pressure to ensure the bit is constantly “peeling” a chip. If the bit starts to “spin” without removing metal, you are destroying both the bit and the workpiece.

Table 3: Stainless Steel Drilling Technical Specifications

| Parameter | Recommended Value for 304/316 Stainless | Why It Matters |

| Bit Material | M35 or M42 Cobalt | Necessary for high red-hardness. |

| Point Geometry | 135° Split Point | Ensures immediate penetration to avoid glazing. |

| Cutting Speed | 30 – 50 Surface Feet per Minute (SFM) | Prevents excessive friction-based heat. |

| Lubrication | High-Pressure Cutting Oil (Sulfurized) | Essential for cooling and reducing friction. |

| Chip Style | Consistent, thick ribbons | Indicates the bit is cutting through the hardened layer. |

Tips: When drilling stainless steel, never use a “peck drilling” cycle that allows the bit to pull entirely out of the cut and rub. Keep constant pressure until the hole is complete. If you must stop, ensure the bit is not spinning against the bottom of the hole when you resume.

5. Specialized Metalworking Scenarios: Hardened Steel and Non-Ferrous Alloys

Beyond standard carbon steel and problematic stainless alloys, professional machinists frequently encounter materials at the opposite ends of the hardness spectrum: hardened tool steels and highly ductile non-ferrous metals like aluminum. Each requires a fundamentally different approach to tool selection and thermal management.

5.1 Best Drill Bits for Hardened Metal (35+ HRC)

Drilling into “hardened” materials—such as AR500 armor plate, automotive leaf springs, or heat-treated D2 tool steel—is a test of both the tool’s substrate and the machine’s rigidity. For these applications, standard HSS will fail instantly.

- M42 Cobalt (8% Cobalt): This is the most resilient HSS-based option. The 8% cobalt content makes it the best cobalt drill bits for metal when you need a balance of heat resistance and enough toughness to survive handheld drilling or less-than-perfect setups.

- Solid Carbide: When the material hardness exceeds 45-50 HRC, carbide is the only viable choice. As the best drill bits for hardened metal, carbide bits can “plow” through hardened layers that would simply melt the tip of a steel bit. However, they require high RPM and zero vibration to prevent chipping.

- TiAlN Coating: For hardened steel, look for Titanium Aluminum Nitride (purple/black) coatings. This coating is unique because it uses the heat of the cut to form a sacrificial layer of aluminum oxide, which acts as a thermal barrier for the bit.

5.2 Best Drill Bit for Aluminum: Managing “The Gummy Effect”

Aluminum is often underestimated. While it is soft, its high ductility makes it “gummy.” In drilling, this leads to Built-Up Edge (BUE), where the aluminum literally welds itself to the cutting edge and fills the flutes, causing the bit to seize and snap.

- Geometry Matters: The best drill bit for aluminum features a high helix angle (faster twist) and polished flutes. This design “flings” the sticky chips out before they can weld to the tool.

- Avoid TiN Coatings: One common mistake is using gold-colored Titanium Nitride (TiN) bits. Aluminum has a chemical affinity for Titanium, which actually increases the likelihood of chip welding.

- The Pro Choice: Use a “Bright Finish” (uncoated and polished) HSS bit or a Zirconium Nitride (ZrN) coated bit. ZrN provides the lubricity needed to keep aluminum moving through the flutes without sticking.

Table 4: Specialized Material Solution Matrix

| Workpiece Material | Challenge | Primary Recommendation | Best Coating |

| Hardened Steel (AR500/Spring) | Abrasive wear/Heat | Best drill bits for hardened metal (Carbide or M42) | TiAlN (AlTiN) |

| Aluminum (6061/7075) | Chip welding/Stickiness | Best drill bit for aluminum (HSS High-Helix) | Uncoated or ZrN |

| Cast Iron | Abrasivity/Dust | Solid Carbide or M35 Cobalt | Black Oxide |

| Titanium Alloys | Low thermal conductivity | Best cobalt drill bits for metal (M42) | TiCN or TiAlN |

5.3 Technical Insight: The “Peck Drilling” Protocol

For both hardened steel and aluminum, Peck Drilling (incrementally drilling and retracting) is a critical technique.

- In hardened steel, it allows the cutting fluid to reach the tip and cool the workpiece.

- In aluminum, it breaks the long, stringy chips that would otherwise clog the flutes.

As a rule of thumb, for holes deeper than three times the bit’s diameter, a peck cycle is mandatory to maintain the integrity of the best bit for drilling metal.

6. Versatility and Boundary Cases: When Metal Bits Meet Other Materials

A professional’s toolkit often demands versatility, and many users wonder if the best drill bit for metal can serve as a “jack-of-all-trades” for the entire workshop. While high-quality HSS and Cobalt bits are incredibly durable, their aggressive cutting geometry—designed to shear through tough alloys—can be a significant liability when applied to softer or more brittle non-metallic substrates.

6.1 Woodworking: Accuracy vs. Blowout

Standard twist bits are frequently included in general-purpose kits labeled as the best drill bits for wood. While a sharp HSS metal bit will certainly create a hole in timber, it lacks the “spur” and “lip” design found in dedicated woodworking tools.

The best drill bits for wood (specifically Brad Point bits) feature a sharp center point that prevents the bit from wandering and peripheral spurs that slice the wood fibers before the main cutters engage. Using a metal bit often results in “blowout” or splintering at the exit point because the 135° metal point “punches” through the wood rather than slicing it cleanly.

6.2 Synthetics: The “Grabbing” Risk in Plastic and Plexiglass

Drilling into polymers requires a delicate touch. The primary failure mode when using metal bits on synthetics is “self-feeding.” Because metal bits are designed to pull themselves into the material, they often “grab” the plastic, leading to catastrophic cracking.

- Plexiglass: This material is notoriously brittle. The best drill bit for plexiglass features a much shallower point angle (often 60° to 90°) and a “dubbed off” cutting edge. This modification changes the action from a “cut” to a “scrape,” which prevents the material from fracturing.

- General Plastics (PVC, HDPE): The best drill bit for plastic should be used at high speeds but with very low feed pressure to avoid melting. If you must use a metal bit, professionals recommend “breaking” the sharp edge of the bit with a whetstone to reduce its aggressiveness.

6.3 Brittle Substrates: Why You Need the Best Drill Bit for Glass

One of the most dangerous mistakes is attempting to use a metal bit on glass or ceramic tile. Metal bits rely on a shearing action that creates high-frequency vibrations—a recipe for immediate shattering.

The best drill bit for glass is either a spear-point carbide bit or a diamond-bonded hole saw. These tools use an abrasive grinding action rather than a cutting action. They require a constant supply of water or coolant to dissipate heat and prevent the glass from undergoing thermal shock.

Table 5: Cross-Material Compatibility & Risk Matrix

| Material | Can I Use a Metal Bit? | Recommended Tool | Primary Risk |

| Hardwood/Softwood | Yes (with caution) | Best drill bits for wood (Brad Point) | Splintering and exit “blowout.” |

| Acrylic / Plexiglass | No (High Risk) | Best drill bit for plexiglass (Slow Helix) | Grabbing and shattering. |

| PVC / Polyethylene | Yes | Best drill bit for plastic | Melting and “self-feeding.” |

| Glass / Ceramic | NEVER | Best drill bit for glass (Diamond/Spear) | Immediate fracture. |

| Masonry / Concrete | NEVER | Masonry Bit (Hammer Drill) | Destroys the metal bit’s edge in seconds. |

6.4 Boundary Case: The “Multi-Material” Hybrid

In recent years, several best drill bit brands have released “Multi-Material” bits. These typically feature a specialized carbide tip ground at an angle that can handle both masonry and metal. While convenient for light construction, they are rarely the best type of drill bit for metal in a dedicated machine shop, as they lack the precision and chip evacuation speed of a true cobalt twist bit.

7. Technical Protocol: Speeds, Feeds, and Coolants

The best bit for drilling metal will still fail if the Surface Feet per Minute (SFM) is ignored.

Table 4: Machinist’s Technical Reference (for 1/4″ Bit)

| Material | SFM (Surface Feet/Min) | Recommended RPM | Feed (IPR) | Lubricant |

| Aluminum | 250 – 300 | 4,500 | 0.008″ | WD-40 / Kerosene |

| Mild Steel | 100 – 110 | 1,600 | 0.005″ | Cutting Oil |

| Stainless 304 | 30 – 50 | 600 | 0.004″ | Moly-Dee / High Pressure |

| Hardened Steel | 15 – 20 | 250 | 0.002″ | Constant Flood Coolant |

8. Brand Analysis: Identifying the Best Drill Bit Brand for 2026

In 2026, the marketplace for cutting tools is more fragmented than ever. With the influx of budget-friendly imports and the rebranding of legacy labels, selecting the best drill bit brand requires looking past the packaging and into the manufacturer’s consistency in heat treatment and metallurgical purity. Based on industrial performance data, tool-life testing, and professional machinist feedback, we have categorized the top brands into three distinct tiers.

8.1 Tier 1: Industrial & Elite Precision (Guhring, OSG, Dormer)

For high-volume CNC production or mission-critical engineering, these brands are the undisputed leaders. They don’t just sell “metal bits”; they sell precision-engineered solutions with micron-level tolerances.

- Guhring: Widely considered the manufacturer of the world’s best cobalt drill bits for metal. Their specialized coatings (like Signum or Fire) and parabolic flute geometries set the benchmark for deep-hole drilling.

- OSG: A Japanese powerhouse famous for their best drill bits for hardened metal. Their carbide tech is the industry standard for drilling high-HRC tool steels.

- Dormer: The European authority on HSS and Cobalt. If you need a bit that maintains its geometry through hundreds of resharpenings, Dormer is the best drill bit brand for longevity.

8.2 Tier 2: Professional Jobsite & MRO (Viking, Cleveland, Milwaukee)

These brands cater to mechanics, maintenance professionals, and contractors who need the best type of drill bit for metal in portable or less-than-ideal conditions.

- Viking (USA Made): Renowned for their “Triple-Flatted” shanks which prevent the bit from slipping in the chuck—a major advantage for high-torque drilling in thick plate. Their “Super Premium” line is frequently cited as the best cobalt drill bits for metal for hand-held use.

- Cleveland: A staple in American machine shops. They provide exceptional consistency for best drill bits for steel at a more accessible price point than the elite industrial brands.

- Milwaukee (Red Helix): A standout in the power tool category. Their variable helix design makes them the best bit for drilling metal when using cordless drills, as they clear chips faster to preserve battery life.

8.3 Tier 3: High-Value DIY & General Trade (Bosch, Irwin)

For general repairs, household projects, or light-gauge metalwork, these brands offer the best balance of cost and performance.

- Bosch: Their multi-material bits are innovative, but their Cobalt M35 sets remain the best drill bit for plastic, aluminum, and light steel repairs for the average homeowner.

- Irwin: Consistent and widely available. While not intended for 24/7 production, they are a reliable best drill bit brand for occasional metal fabrication.

Table 8: Brand Ranking Matrix for 2026

| Tier | Brand | Specialization | Best For… | Precision Rating |

| Elite | Guhring | Industrial M42 & Carbide | Aerospace, CNC, High-Volume | 10/10 |

| Professional | Viking / PTD | M35 Cobalt (Premium) | Mechanics, Thick Plate, MRO | 9/10 |

| Pro-Contractor | Milwaukee | Variable Helix HSS/Co | Cordless Drills, Speed | 8/10 |

| General Use | Bosch | M35 Sets & Multi-Mat | Best drill bit for plastic/DIY | 7/10 |

8.4 The “Counterfeit” Warning

In the current market, “Cobalt” is often used as a marketing buzzword rather than a metallurgical fact. Many low-end sets are merely Cobalt-Coated rather than true Cobalt-Alloy. A coating will wear off after the first sharpening, whereas a true M35 or M42 bit from a reputable best drill bit brand will maintain its properties through its entire lifespan.

9. Troubleshooting: Failure Mode Analysis

Even when using the best drill bit for metal, failure is inevitable if operational parameters shift. However, a professional machinist doesn’t just replace a broken tool; they perform a “post-mortem” on the failed bit to diagnose the root cause. By analyzing the wear patterns on your best cobalt drill bits for metal, you can adjust your process to prevent future downtime.

9.1 Outer Corner Wear (The “Burned” Tip)

This is the most common failure in metalworking. The outer corners of the cutting lips are the fastest-moving parts of the drill bit and generate the most heat.

- The Symptom: The sharp corners of the bit are rounded off, discolored (blue or black), or completely melted.

- The Cause: Excessive RPM. You have exceeded the Surface Feet per Minute (SFM) limit for that specific metal.

- The Solution: Reduce your speed. If you are using the best drill bits for steel, ensure you are using a sulfur-based cutting oil to carry heat away from those critical corners.

9.2 Chipped Cutting Edges

Unlike melting, chipping is a mechanical failure rather than a thermal one.

- The Symptom: Small “nicks” or chunks of metal missing from the cutting lips.

- The Cause: Vibration (Chatter) or Excessive Feed. This is common with Solid Carbide or M42 cobalt bits due to their high hardness and lower toughness. It often happens when the workpiece is not clamped securely or the drill press spindle has too much “slop” (runout).

- The Solution: Increase the rigidity of your setup. Check that the workpiece is rock-solid and reduce the feed rate slightly.

9.3 Snapped Bits (Catastrophic Fracture)

A snapped bit is usually the result of excessive torque or chip congestion.

- The Symptom: The bit breaks cleanly across the flutes or near the shank.

- The Cause: Chip Packing. In deep holes, if the chips cannot escape the flutes, they compress into a solid mass, causing the bit to seize. This is why a parabolic flute is often the best type of drill bit for metal for deep-hole applications.

- The Solution: Use a “Peck Drilling” cycle to clear chips. Increase lubrication to help the chips slide up the flutes.

9.4 Web Failure and “Walking”

- The Symptom: The bit splits down the center (the web) or fails to start a hole accurately.

- The Cause: Excessive Thrust Force without a pilot hole or a dull split point. If the web is too thick and the point is not “thinned,” the pressure required to move the bit forward will eventually split the core.

- The Solution: Ensure you are using a 135° split point, which is the best bit for drilling metal for self-centering and lower thrust requirements.

Table 9: Machinist’s Troubleshooting Guide

| Visual Symptom | Primary Cause | Immediate Correction |

| Rounded Outer Corners | Excessive RPM (Heat) | Decrease RPM / Increase Coolant |

| Chipped Lips | Chatter / Vibration | Improve Clamping / Reduce Feed |

| Snapped in Flutes | Chip Clogging | Use Peck Cycle / Parabolic Flute |

| Glazed Workpiece | Insufficient Feed (Rubbing) | Increase Pressure / Sharpen Bit |

| Oversized Hole | Uneven Sharpening | Check Symmetry of Point Angles |

Summarize

Selecting the best drill bits for metal is a precise science of matching tool metallurgy—specifically M35 Cobalt for stainless steel or Solid Carbide for hardened alloys—with a 135-degree split point geometry to ensure immediate penetration and thermal stability. While choosing a reputable best drill bit brand like Guhring or Viking is essential for consistency, the ultimate success of the cut depends on adhering to professional protocols like low RPM and constant feed pressure to prevent work hardening and premature tool failure. Ultimately, the best type of drill bit for metal is one that balances “red hardness” with structural toughness, transforming a challenging task into a precise act of engineering.