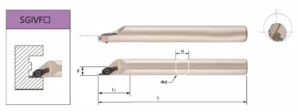

Grooving Tool Holder

A Grooving Tool Holder is a specialized tool holder designed to securely grip and position a grooving tool during machining operations, primarily on a lathe. Its main purpose is to create grooves of specific widths and depths on a workpiece. The holder ensures the grooving tool remains stable and rigid, which is crucial for achieving accurate groove dimensions and a good surface finish.

These tool holders come in various designs to accommodate different types of grooving inserts and machining requirements. Some common variations include holders for external grooving, internal grooving (for creating grooves inside a bore), and face grooving (for grooves on the face of a workpiece). The clamping mechanism within the holder is critical for preventing the thin grooving insert from vibrating or breaking under cutting forces.

A high-quality grooving tool holder is essential for efficient and precise grooving operations. It contributes to increased productivity by allowing for higher cutting speeds and feed rates. Furthermore, it enhances tool life by providing proper support and reducing stress on the cutting insert. Choosing the right grooving tool holder depends on factors like the type of grooving operation, the material of the workpiece, and the machine tool being used. Ultimately, it plays a vital role in producing accurate and consistent grooves in a wide range of manufacturing applications.

Frequently Asked Questions

Creating grooves of specific widths and depths on a workpiece, typically on a lathe.

External for outside surfaces, internal for inside bores, face for the end face of a part.

Grooving inserts are the actual cutting edges that are held and supported by the tool holder.

Yes, specialized grooving tool holders and inserts are often used for parting off operations.

Consider the type of groove, workpiece material, machine setup, and required precision.

Workpiece material, desired groove width and depth, cutting speed, and feed rate.

Metals like steel, aluminum, stainless steel, as well as plastics and other materials.

Typically, you need different inserts for different groove widths, but the same holder might accommodate various widths within a certain range.

Screw clamp, lever clamp, wedge clamp are common types.

Yes, many grooving tool holders are designed with features suitable for automated tool changing and high-precision CNC operations.

Contact Us for Your Tool Holders

Please note: We are a wholesale supplier and have minimum order quantities.