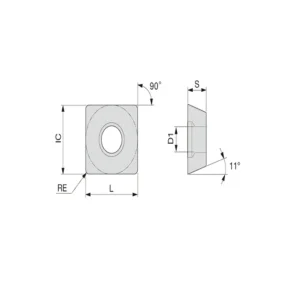

SPMT insert

SPMT insert is another type of cutting insert used in machining operations, particularly in milling.

SPMT Insert Specification Guide

- S: This usually refers to the shape of the insert. In this case, ‘S’ typically stands for “Square” shape.

- P: Often indicates a positive rake angle, which helps in reducing cutting forces.

- M: Commonly stands for “Medium,” which could refer to the feed rate, chip breaker design, or other cutting characteristics.

- T: Often denotes the thickness or a particular feature of the insert.

SPMT Insert introduce

SPMT inserts are generally known for their versatility in milling operations. The square shape provides four cutting edges, allowing for extended use before replacement is necessary. These inserts are often favored for their ability to handle a variety of cutting conditions and materials, particularly in face milling and shoulder milling operations.

These inserts are typically used in operations requiring good surface finish and are often suitable for machining steel, stainless steel, and cast iron, among other materials. The positive rake angle helps in reducing cutting forces, making them suitable for less rigid setups or when working with more challenging materials.

SPMT Insert Specification

- Square design providing four cutting edges for extended tool life and cost-effectiveness

- Positive rake angle for reduced cutting forces and improved chip evacuation

- Medium chip breaker geometry for efficient chip control across various materials

- Precision-ground edges for superior surface finish and dimensional accuracy

Ideal for machining a wide range of materials including steel, stainless steel, and cast iron, the SPMT insert delivers consistent performance in both roughing and finishing operations. Its positive geometry promotes lower cutting forces, making it suitable for less rigid setups and more challenging materials.

The SPMT insert excels in applications requiring a balance between high productivity and superior surface quality. Its design ensures stability during cuts, reducing vibration and extending tool life even under demanding conditions.

Easy to index and replace, the SPMT insert minimizes downtime and maximizes efficiency in milling operations. With four cutting edges per insert, it offers excellent value and reduces tooling costs over time.

Experience the perfect combination of versatility, precision, and cost-effectiveness with the SPMT square milling insert for your face and shoulder milling needs.

Why Choose Our Inserts?

Versatile Performance

Our SPMT inserts excel in both face milling and shoulder milling operations, offering flexibility for various machining tasks with a single insert type.

Cost-Effective Solution

With four cutting edges per insert, our SPMT design provides excellent value, significantly reducing your overall tooling costs.

Extended Tool Life

Manufactured from premium-grade carbide materials, our SPMT inserts offer superior wear resistance, ensuring longer tool life even under demanding conditions.

Reduced Cutting Forces

The positive rake angle design decreases cutting forces, making these inserts ideal for machining less rigid workpieces or when using less powerful machines.

Our Production Capability