Square End Mill

Are you tired of subpar square end mill that compromise your machining precision and productivity? Imagine a tool that cuts through the toughest materials like butter, leaving flawless finishes and saving you valuable time and resources.

| Custom size: 4mm,6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm,customized size | |||

| Advantages: High Precision,Good Surface & Performace | |||

| Material: | YG10X /MH10FS&UH8(China)/K44 & K40 (German)/K44UF&K88UF(Cobalt collar) | ||

| Material: | Tungsten Carbide | ||

| HRC: | 45/55/58/60/65 | ||

| Product Type: | Customized solid carbide cutting tools according to customer requirements | ||

| Coating: | Altin, Tialn, Tisin, Tin, DLC,Nano, Diamond | ||

| Helix Angle: | 10degree,15degree,25degree,35degree,45degree,55degree | ||

| Machining machine: | Imported Australian Anka machines and German Walther precision manufacturing | ||

| Suitable For: | Steel, Stainless Steel, Die Steel, Mould Steel, Carbon Steel, Cast Iron, Copper, etc. | ||

Square end mills gallery

Step into the world of unparalleled cutting precision with ONMY TOOLINGS’s extraordinary lineup of square end mills. From micro-machining marvels to heavy-duty workhorses, our diverse range is designed to conquer every milling challenge you face.

Why our square end mill?

Unparalleled Precision: Our square end mills maintain dimensional accuracy within microns, ensuring perfect 90-degree corners and flat surfaces.

Extended Tool Life: Advanced coating technologies and optimized geometries significantly increase tool longevity, reducing downtime and replacement costs.

Superior Surface Finish: Achieve mirror-like surfaces right off the machine, minimizing post-processing requirements.

Increased Material Removal Rates: Our innovative cutting edge designs allow for higher feed rates and depths of cut, boosting your productivity.

What can we do?

Imagine the competitive edge you’ll gain with tools that consistently deliver superior results, reduce costs, and increase your machining capabilities. With ONMY TOOLINGS’s square end mills, you’re not just buying a tool – you’re investing in a partnership dedicated to your success.

What sets our square end mills apart is our unwavering commitment to innovation and quality:

Cutting-Edge R&D: Our team of expert engineers constantly pushes the boundaries of tool design, incorporating the latest advancements in material science and manufacturing techniques.

Custom Solutions: We don't believe in one-size-fits-all. Our in-house design team works closely with you to develop tailored tooling solutions for your unique challenges.

Rigorous Quality Control: Every square end mill undergoes extensive testing and inspection, ensuring consistent performance and reliability.

Comprehensive Support: Our technical experts are always ready to assist you in optimizing your machining processes for maximum efficiency.

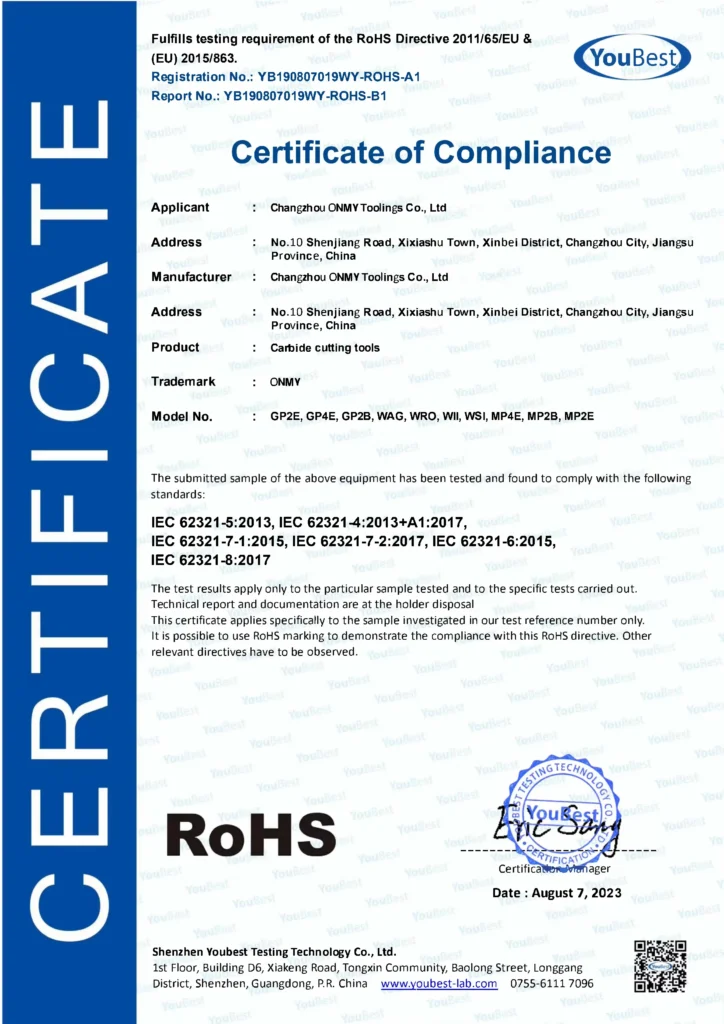

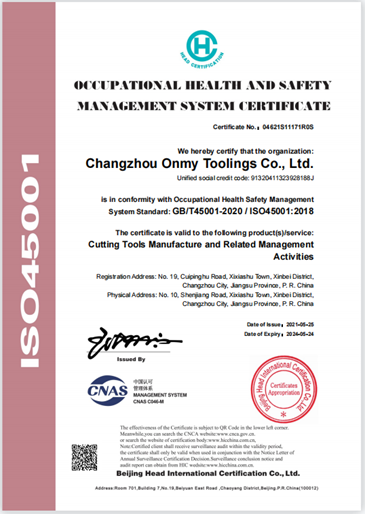

Factory Certification

As a responsible factory, you want the product to do well, in addition to the necessary talent, but also need a series of quality certification, because you believe more in the system certification:

Request A Quote Today

Don’t let inferior tools hold you back any longer. Experience the ONMY TOOLINGS difference today:

- Request a free consultation with our tooling experts.

- Order a sample square end mill and put it to the test in your own facility.

- Contact us for a customized quote tailored to your specific needs.