OD Turning Tool Holder

An OD (Outer Diameter) Turning Tool Holder is a fundamental tool used in machining operations, specifically on lathes and turning centers, to hold cutting inserts for shaping the external surfaces of cylindrical workpieces. Its primary function is to securely clamp the cutting insert in a precise position, providing the necessary rigidity and stability for accurate material removal and achieving the desired dimensions and surface finish on the outer diameter of the part.

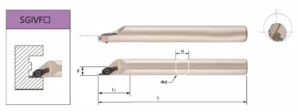

These tool holders come in a wide variety of styles and sizes to accommodate different machine tool interfaces, workpiece materials, and machining requirements. Common types include straight shank holders, angled shank holders, and holders designed for specific insert shapes such as triangular, square, rhombic, or round. The clamping mechanisms can vary, often involving screws, levers, or wedges to firmly secure the insert.

A well-chosen OD Turning Tool Holder is crucial for efficient and effective turning operations. It ensures that the cutting insert is held at the correct cutting angle and with sufficient support to withstand the forces generated during machining. This helps to minimize vibration, reduce tool deflection, and improve the overall accuracy and quality of the turned part. Some advanced OD turning tool holders may also incorporate features like internal coolant delivery to enhance chip evacuation and extend tool life. Selecting the appropriate OD turning tool holder depends on factors such as the type of turning operation (roughing, finishing), the material being machined, and the specific geometry of the cutting insert being used.

Frequently Asked Questions

Specifically for holding cutting inserts to machine the outer diameter of a cylindrical workpiece.

“OD” stands for Outer Diameter.

Triangular, square, rhombic, round, diamond, and others, depending on the holder design.

Consider the type of turning (roughing, finishing), workpiece material, machine tool interface, and the desired insert shape and size

The shank size must match the tool holding capacity of your lathe’s tool post for secure mounting.

Vibration, tool deflection; a rigid and well-designed holder minimizes these issues.

While the basic function is the same, CNC lathes often use tool holders with specific interfaces for automatic tool changing.

Improved chip evacuation, reduced cutting temperature, and extended tool life.

The direction in which the cutting edge is oriented, determining the direction of feed along the workpiece.

Contact Us for Your Tool Holders

Please note: We are a wholesale supplier and have minimum order quantities.