4 ağızlı parmak freze

4 kanallı parmak freze; metal, plastik ve ahşap gibi malzemelerin işlenmesi için frezeleme işlemlerinde yaygın olarak kullanılan döner bir kesici takımdır. Silindirik gövdesi boyunca uzanan dört helisel kesme kenarına (oluk) sahiptir ve bu sayede verimli malzeme kaldırma ve pürüzsüz yüzey finisajları sağlar. Dört kanallı tasarım, talaş tahliyesi ve kesme stabilitesi arasında bir denge sağlayarak çok çeşitli uygulamalar için uygun hale getirir. Bu parmak frezeler hem yandan kesme hem de dalma işlemlerini gerçekleştirebilir ve genellikle imalat, havacılık ve otomotiv gibi çeşitli sektörlerde kanal açma, profil oluşturma ve konturlama gibi görevler için kullanılır.

4 ağızlı parmak freze Uygulama

4 ağızlı parmak frezeler, talaşlı imalatta geniş bir uygulama alanına sahiptir. İşte ana kullanım alanlarına kısa bir genel bakış:

- Genel frezeleme işlemleri

- Kanal açma ve kanal frezeleme

- Profil oluşturma ve konturlama

- Yan frezeleme

- Daldırmalı kesim

- Bitirme pasları

- Daha sert malzemelerin işlenmesi

- Yüksek hızlı işleme

- Havacılık ve otomotiv endüstrilerinde hassas çalışma

- Kalıp ve kalıp yapımı

Bu parmak frezeler özellikle çelik, paslanmaz çelik ve alüminyum gibi metallerle çalışırken etkilidir. Genellikle pürüzsüz yüzeyler üretme ve boyutsal doğruluğu koruma yetenekleri nedeniyle tercih edilirler.

4 ağızlı parmak freze Özellikleri

4 ağızlı parmak frezeler, çeşitli işleme uygulamalarında yaygın olarak kullanılan çok yönlü bir kesme takımıdır. İşte temel özelliklerinden dördü:

1. Artan Çekirdek Kalınlığı ve Gücü

- Daha az kanallı parmak frezelerle karşılaştırıldığında, 4 kanallı parmak frezeler daha kalın bir çekirdeğe sahiptir.

- Bu daha kalın çekirdek, kesme sırasında takım sapmasını azaltarak gelişmiş sertlik sağlar.

- Bu da daha iyi hassasiyet ve gelişmiş yüzey kalitesi anlamına gelir.

2. Azaltılmış Çip Yükü

- Dört oluk, kesme yükünü daha eşit bir şekilde dağıtır.

- Kanal başına düşen talaş yükünün azalması daha düzgün kesme işlemi sağlar.

- Talaş birikimini önlemeye yardımcı olur ve genel kesme verimliliğini artırır.

3. Çok Yönlü Uygulama

- 4 kanallı parmak frezeler, dökme demir, takım çeliği, paslanmaz çelik ve ısıl işlem görmüş çelikler dahil olmak üzere çok çeşitli malzemeler için uygundur.

- Kanal açma, profil oluşturma ve cep açma gibi çeşitli işleme operasyonları için kullanılabilirler.

4. Geliştirilmiş Yüzey İşlemi

- Azalan talaş yükü ve artan rijitlik sayesinde 4 ağızlı parmak frezeler, daha az ağızlı parmak frezelere kıyasla daha iyi yüzey finisajları üretir.

- Bu, özellikle pürüzsüz bir yüzeyin gerekli olduğu uygulamalar için faydalıdır.

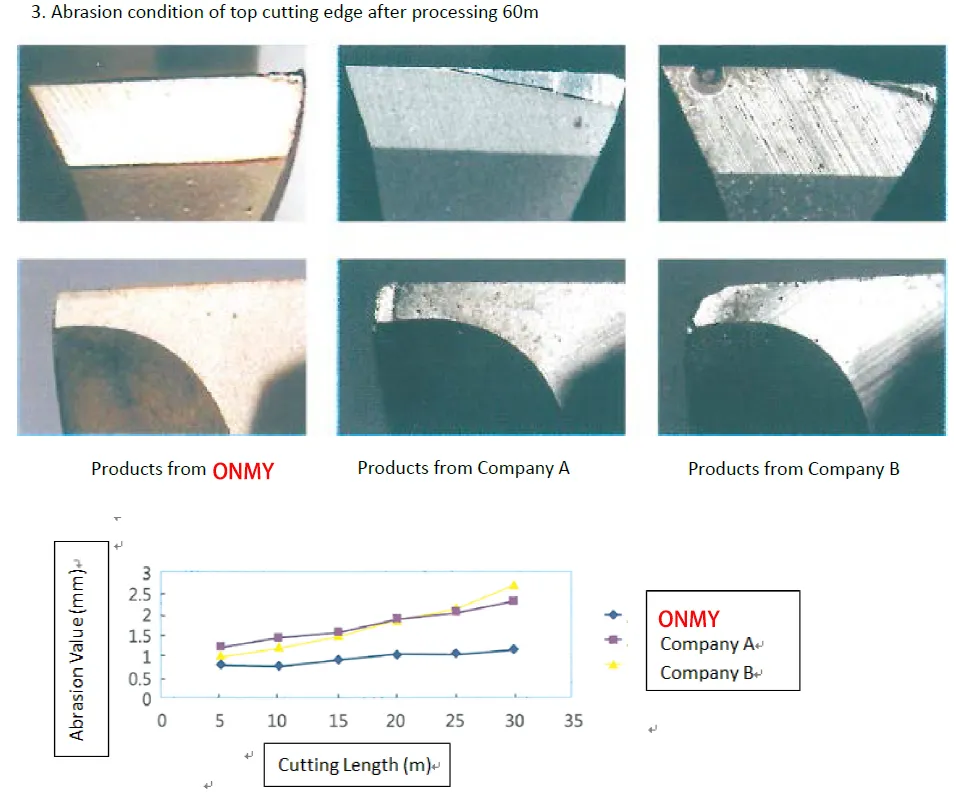

Çinli tedarikçilerin çoğu aynı kaliteye sahip, ama biz aynı değiliz, neden?

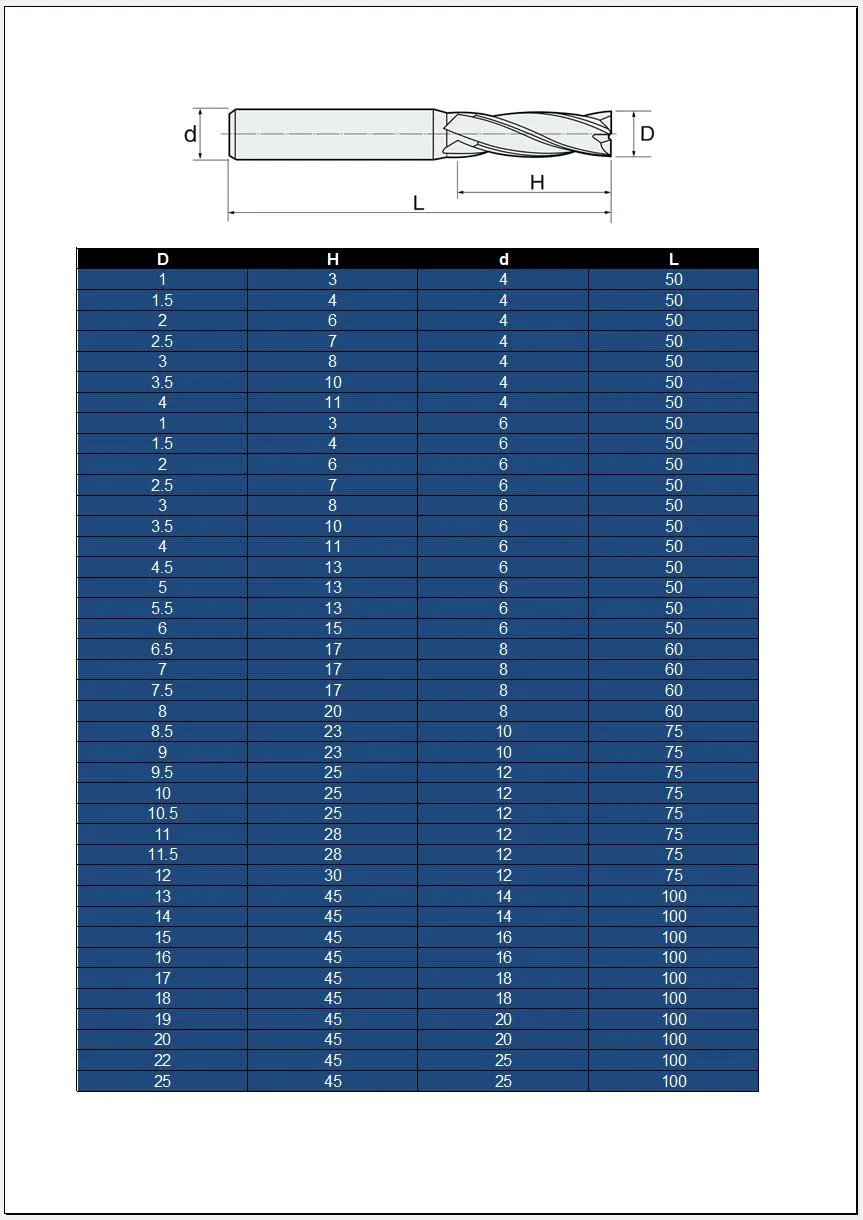

3 ağızlı parmak freze kataloğu

3 Flüt Frezeler Kataloğu, geniş bir kullanıcı yelpazesi için 3 Flüt Frezeler ürün bilgisi sağlayan profesyonel bir araçtır.

ONMY TOOLINGS Farkı

Bizi ayıran şey tek ağızlı parmak freze ayrı mı? Bu, bizim benzersiz kombinasyonumuzdur:

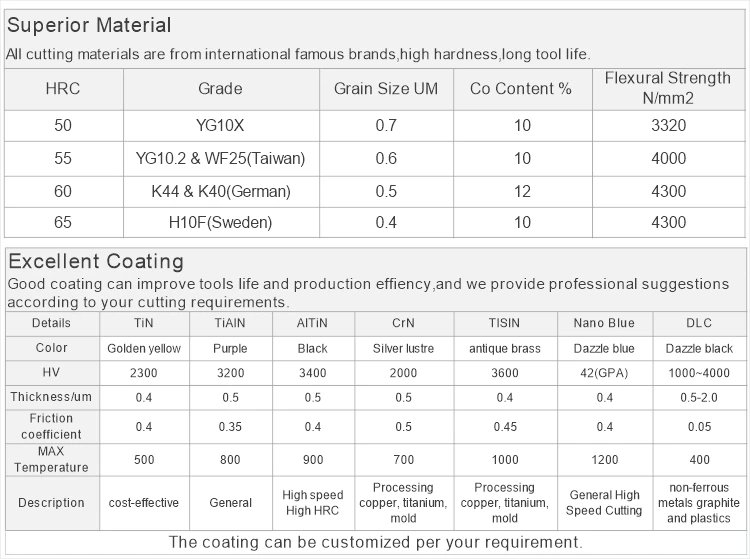

Gelişmiş Karbür Formülasyonları

Güç ve aşınma direnci için optimize edilmiş tescilli mikro taneli karbür karışımları kullanıyoruz.

Yenilikçi Geometriler

Patentli oluk tasarımlarımız talaş tahliyesini en üst düzeye çıkarır ve kesme kuvvetlerini en aza indirir.

Son Teknoloji Kaplamalar

Isı direncini artıran ve sürtünmeyi azaltan nano katmanlı PVD kaplamalar uyguluyoruz.

Hassas Taşlama

Çok eksenli CNC taşlama makinelerimiz ±0,0005 inç kadar sıkı toleranslara ulaşır.

Fabrika Sertifikasyonu

Bu sertifikalar sadece süslü rozetler değildir - ürettiğimiz her alette tutarlı, en üst düzey kalitenin garantisidir. Kalite kontrol sürecimiz, her aletin titiz standartlarımızı karşıladığından emin olmak için kritik boyutların 100% incelemesini ve gelişmiş aşınma direnci testini içerir.

Mükemmellik Yolculuğumuz

Hikayemiz küçük bir atölyede büyük bir hayalle başladı: dünyanın en iyi bull nose parmak frezelerini yaratmak. Bugün, en son CNC taşlama teknolojisi ve gelişmiş kaplama sistemleriyle donatılmış son teknoloji ürünü 50.000 metrekarelik bir tesis işletiyoruz. Ancak gerçek gücümüz, ürettiğimiz her alete uzmanlıklarını katan tutkulu mühendisler ve yetenekli ustalardan oluşan ekibimizde yatıyor.

Özel ihtiyaçlarınıza göre uyarlanmış özel parmak frezelere sahip olmak varken neden hazır çözümlerle yetinesiniz ki? Şirket içi araştırma ve geliştirme ekibimiz sürekli olarak işleme teknolojisinde mümkün olanın sınırlarını zorluyor. Malzeme bilimi ve kesici takım tasarımının ön saflarında yer almak için önde gelen üniversiteler ve endüstri ortaklarıyla işbirliği yapıyoruz.

Sadece bizim sözümüze güvenmeyin. İşte memnun müşterilerimizin söyledikleri:

Mutlu Müşterim!

Özel Teklifinizi Şimdi Alın!

Not: Toplu indirimler sunduğumuzu söylemiş miydik? Ne kadar çok sipariş verirseniz, o kadar çok tasarruf edersiniz!

- Rakipsiz Fabrika Doğrudan Fiyatlandırması: Aracıyı devre dışı bırakın ve perakende fiyatlarına kıyasla 40%'ye kadar tasarruf edin. Verimli üretim sürecimiz, üstün kaliteyi rekabetçi fiyatlarla sunmamızı sağlar.

- Yıldırım Hızında Teslimat: Kolaylaştırılmış üretim sürecimizle, sektör lideri geri dönüş süreleri sunuyoruz. Özel parmak frezelerinizi 7 gün gibi kısa bir sürede teslim alın! Anında sevkiyat için geniş bir standart boyut envanterine sahibiz.

- Kişiselleştirilmiş Hizmet: Uzman mühendislerden oluşan ekibimiz, benzersiz işleme zorluklarınız için mükemmel çözümü bulmanıza yardımcı olmaya hazırdır. Özel ihtiyaçlarınızı analiz etmek ve ideal takım özelliklerini önermek için ücretsiz danışmanlık hizmeti sunuyoruz.

Sıkça Sorulan Sorular

- Daha yumuşak malzemelerde kaba işleme operasyonları için: 3 kanallı bir parmak freze iyi bir seçim olabilir.

- Finisaj işlemleri veya daha sert malzemeler için: Genellikle 4 ağızlı parmak freze tercih edilir

4 ağızlı parmak frezeler öncelikle şunlar için kullanılır:

- Metal ve plastiklerde genel frezeleme işlemleri

- Kanal açma ve oluk açma

- Karmaşık şekillerde profil oluşturma ve konturlama

- Düz kenarlar oluşturmak için yan frezeleme

- Pürüzsüz yüzeyler elde etmek için son işlem pasoları

- Delik veya cep oluşturmak için daldırmalı kesim

- Yüksek hızlı işleme operasyonları

- Havacılık ve otomotiv parçalarında hassas çalışma

- Kalıp ve kalıp yapımı

- Paslanmaz çelik gibi daha sert malzemelerin işlenmesi

Özellikle çelik ve alüminyum gibi malzemelerde kesme verimliliği ve yüzey kalitesi dengesi nedeniyle tercih edilirler. Dört ağızlı tasarım, iki ağızlı frezelere kıyasla daha hızlı ilerleme hızlarına olanak sağlarken, iyi talaş tahliyesini de korur.

2 Flüt Frezeler:

- Daha iyi talaş tahliyesi

- Daha yumuşak malzemeler için idealdir (örn. alüminyum, pirinç, plastik)

- Derin cepler ve yuvalar için tercih edilir

- Daha yüksek ilerleme hızları mümkün

- Daldırmalı kesim için daha iyi

- Kaba işleme operasyonları için daha uygun

4 Flüt Frezeler:

- Daha pürüzsüz yüzeyler için daha fazla kesme kenarı

- Daha sert malzemeler için daha iyidir (örn. çelik, paslanmaz çelik)

- Artırılmış stabilite ve azaltılmış titreşim

- Yan frezeleme işlemleri için üstün

- Sıkı toleransları korumak için daha iyi

- Son işlem operasyonları için daha uygun

Temel farklılıklar:

- Talaş boşluğu: 2 flüt daha iyi

- Yüzey kalitesi: 4 oluk genellikle üstün

- Malzeme uygunluğu: daha yumuşak için 2 oluk, daha sert için 4 oluk

- Kesme hızı: 4 oluk tipik olarak daha hızlı

- Uygulama: kaba işleme için 2 oluk, ince işleme için 4 oluk

Evet, alüminyum için 4 ağızlı parmak frezeler kullanılabilir, ancak bunlar her zaman en uygun seçim değildir. İşte kısa bir açıklama:

- Mümkün, ancak ideal değil: 4 ağızlı parmak frezeler, özellikle finisaj işlemlerinde alüminyum işleyebilir.

- Talaş tahliyesi: Ana endişe, alüminyumun uzun, telli talaşlar üretme eğiliminde olmasıdır. 4 oluklu frezelerde talaş tahliyesi için oluklar arasında daha az boşluk vardır.

- Isı birikimi: Daha fazla yiv daha fazla ısı üretimine yol açabilir, bu da malzemenin sakızlaşmasına neden olabileceğinden alüminyum için sorunludur.

- Daha iyi alternatifler: Alüminyum için genellikle 2 veya 3 ağızlı parmak frezeler tercih edilir. Daha iyi talaş boşluğu ve ısı dağılımı sunarlar.

- Özel durumlar: Alüminyumun yüksek hızda işlenmesi veya yüzey finişinin kritik olduğu finiş pasoları için 4 ağızlı bir takımdan yararlanılabilir.

- Kaplamalar: Alüminyum üzerinde 4 ağızlı freze kullanıyorsanız, sürtünmeyi ve ısıyı azaltmak için uygun kaplamalara sahip olanları arayın.

Özetle, alüminyum üzerinde 4 ağızlı parmak freze kullanmak mümkün olsa da talaş boşaltma endişeleri nedeniyle genellikle ilk tercih değildir. En iyi takım, özel işleme ve gereksinimlere bağlıdır.

- Yığın malzeme kaldırma: İş parçalarından büyük miktarlarda malzemenin hızlı bir şekilde çıkarılması.

- Hogging: Kaba şekiller veya boşluklar oluşturmak için agresif kesim.

- Kaba işleme pasoları: Bir iş parçasını sonraki finisaj işlemleri için hazırlama.

- Yüksek talaş kaldırma oranları (MRR): Birim zamanda kaldırılan malzeme hacminin maksimize edilmesi.

- Daha sert malzemelerin işlenmesi: Çelik ve paslanmaz çelik gibi sert malzemelerde etkilidir.

- Cep oluşturma: Bir iş parçasındaki alanları hızlıca oymak.

- Stok çıkarma: Ham stoğun boyutunu hızla küçültme.

- Uyarlanabilir frezeleme: Verimli malzeme kaldırma için modern CNC stratejilerinde kullanılır.

- Yiv açma: Kaba yarıklar veya oluklar oluşturma.

- Finisaj için hazırlık: İş parçasının son boyutlandırma ve yüzey finisajı için ayarlanması.

Alüminyumun işlenmesi için genellikle 2 ağızlı parmak frezeler tercih edilir.

- Çip tahliyesi: Alüminyum uzun, lifli talaşlar üretir. Bir flütteki daha geniş boşluklar 2 ağızlı parmak freze daha iyi talaş temizliği sağlayarak talaş birikmesini ve tıkanmayı önler.

- Malzeme kaldırma oranı (MRR): 4 kanallı parmak frezeler teorik olarak daha yüksek MRR elde edebilirken, talaş boşaltma sorunu alüminyum işlemede genellikle bu avantajı dengeler.

- Alet ömrü: Çoğu durumda 2 ağızlı parmak frezeler, kesme kenarlarındaki gerilimin azalması nedeniyle alüminyumda daha uzun takım ömrü sağlayabilir.

İstisnalar

Bununla birlikte, alüminyum için 4 ağızlı bir parmak frezenin düşünülebileceği durumlar vardır:

- Bitirme işlemleri: Çok ince finisajlar için, daha yumuşak kesme hareketi nedeniyle 4 ağızlı bir parmak freze tercih edilebilir.

- Küçük çaplı parmak frezeler: Bazı durumlarda, küçük çaplı parmak frezelerde 4 kanal daha iyi sağlamlık sunabilir.

- Yüksek hızlı işleme (HSM): Belirli HSM koşulları altında, 4 ağızlı bir parmak freze etkili olabilir.

Nihayetinde, en iyi seçim aşağıdaki gibi belirli faktörlere bağlıdır:

- Alüminyum alaşım

- Kesme koşulları (hız, ilerleme, kesme derinliği)

- İstenen yüzey kalitesi

- Alet kullanılabilirliği