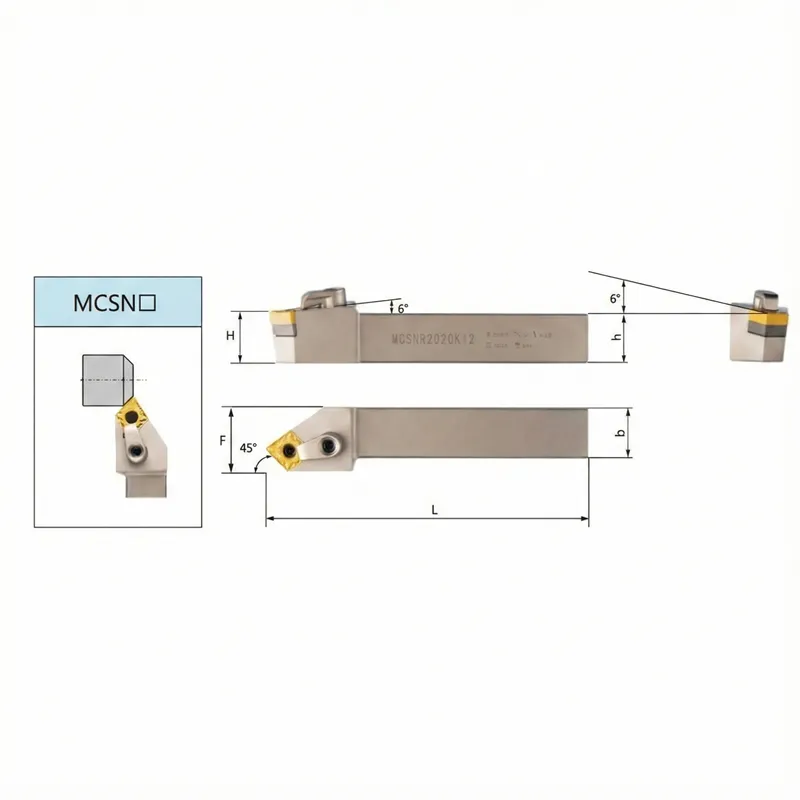

The MCSNR/L Turning Tool Holder is a robust lathe tool holder engineered for high-stability external turning and heavy-duty roughing. Featuring a 45-degree approach angle, this tool holder for turning effectively balances cutting forces to reduce tool wear and vibration. Powered by an M-type multi-lock system, it provides a secure fit for CNMG, CNMA, and CNMM inserts, making it a reliable choice for demanding CNC environments.

Contact our sales team to discover all of your pricing options.

High-Stability MCSNR/L Tool Holder with 45° Lead Angle

The MCSNR/L tool holder is a specialized high-performance option among CNC turning tool holder types. Its 45-degree approach angle is specifically designed to distribute cutting pressure more evenly across the carbide edge compared to 95-degree holders. This makes the MCSNR/L a superior lathe turning tool holder for high-removal rate operations where tool longevity and stability are paramount.

Multi-Insert Compatibility: CNMG, CNMA, and CNMM

Designed for versatility, the MCSNR/L pocket is precision-machined to accommodate various CN-series inserts, allowing you to adapt to different workpiece materials:

-

CNMG Inserts: The standard for versatile steel and stainless steel turning.

-

CNMA Inserts: Optimal for cast iron machining, offering flat-top stability.

-

CNMM Inserts: Reinforced for heavy roughing and interrupted cuts, providing extra edge strength.

Rigid M-Type Double Clamping for Heavy Cuts

To handle the intense loads of 45-degree turning, the MCSNR/L utilizes the M-type clamping mechanism. This “Multi-lock” system secures the indexable turning tool holders with both a top clamp and a center pin. This dual-locking action prevents insert rotation and lifting, outperforming standard screw-down lathe insert holders in heavy-duty and large-feed applications.

Specifications Table

| Feature | Details |

| Model Number | MCSNR (Right Hand) / MCSNL (Left Hand) |

| Primary Category | Indexable Turning Tool Holders |

| Clamping System | M-Type (Double Clamp / Multi-lock) |

| Approach Angle | 45° (Ideal for Heavy Roughing) |

| Compatible Inserts | CNMG, CNMA, CNMM (Size 1204 / 432) |

| Body Material | Hardened High-Strength Alloy Steel |

| Application | Heavy Roughing, Chamfering, High-Feed Turning |

Q: What is the main advantage of the 45-degree approach angle on the MCSNR/L?

A: The 45° angle on the MCSNR/L provides a better balance between axial and radial forces. This reduces the risk of vibration and allows for much higher feed rates compared to 95° holders. It is an excellent turning tool holder for removing large amounts of material quickly while protecting the insert’s cutting edge.

Q: Can I use the MCSNR/L for turning 90-degree shoulders?

A: No. Due to the 45-degree lead angle, this holder is not suitable for square shoulders. It is primarily used for longitudinal turning, chamfering, and roughing operations where the shoulder geometry is not a constraint.

Q: Is the M-type clamp better than the P-type for 45-degree cutting?

A: Yes. In high-feed 45-degree cutting, the insert experiences significant upward pressure. The M-type double clamp (top and center) provides more secure downward force than a P-type lever system, ensuring the CNMG holder remains stable under extreme loads.

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options