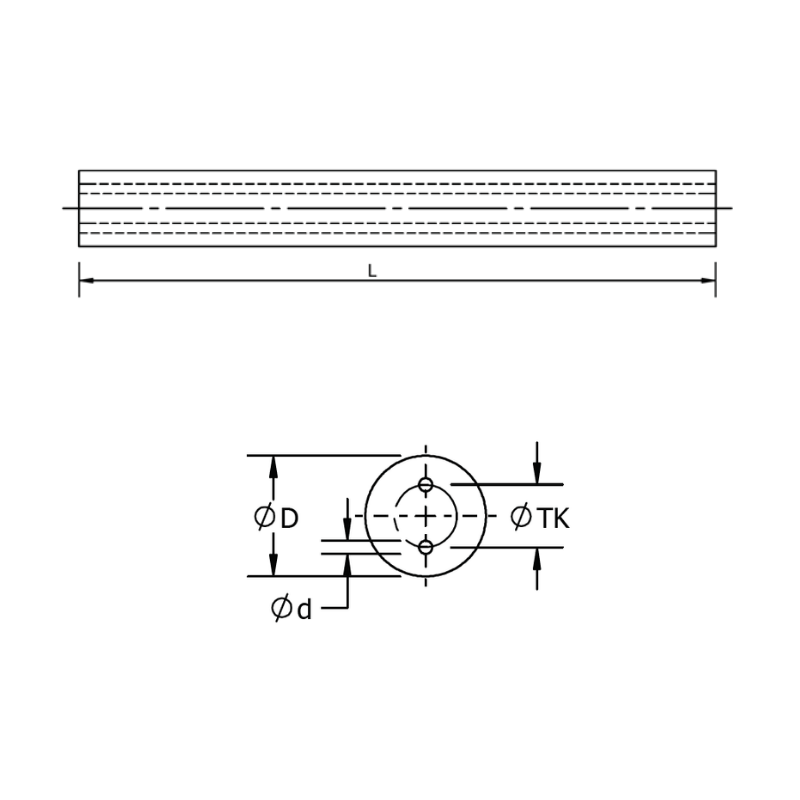

Double Holes Tungsten Carbide Rod

Product Features:

-

Made of high-quality tungsten carbide with cobalt binder for excellent hardness and toughness.

-

Designed with double straight coolant holes for efficient cooling and chip evacuation.

-

High wear resistance ensures longer tool life and stable cutting performance.

-

Suitable for manufacturing high-performance drills, reamers, and end mills.

-

Available in both ground and unground versions with precise dimensional tolerances.

Contact our sales team to discover all of your pricing options.

Double straight holes tungsten carbide rods are premium tool blanks designed with two parallel coolant channels that pass through the rod body. Compared to solid carbide rods, the double straight hole structure allows for direct and efficient coolant delivery to the cutting edge, ensuring superior heat dissipation and smooth chip evacuation. This reduces tool wear, minimizes cutting edge damage, and significantly improves machining efficiency.

Manufactured using advanced powder metallurgy technology, these rods combine tungsten carbide and cobalt to achieve exceptional hardness (HRA 89–93), excellent wear resistance, and reliable fracture toughness. The uniform grain structure and strict dimensional control provide consistent performance in demanding cutting operations.

Double straight holes tungsten carbide rods are widely used in the production of precision cutting tools, including drills, reamers, and end mills, especially for machining stainless steel, hardened steel, cast iron, and other challenging materials. They are available in ground and unground finishes, with standard diameters from 3 mm to 20 mm and lengths up to 330 mm. Customized specifications are also available to meet special toolmaking requirements.

By choosing double straight holes tungsten carbide rods, manufacturers benefit from improved tool durability, enhanced cooling efficiency, and stable cutting performance, making them a preferred solution in aerospace, automotive, and mold-making industries.

| Blank-D | TK-Double Hole Spacing | Internal Diameter-d | Grinding-D | Length-L | |||

|---|---|---|---|---|---|---|---|

| External Diameter(mm) | Tolerance(mm)(+1.5mm) | Double Hole Spacing-TK(mm) | Tolerance(mm)(+1.5mm) | Internal Diameter-d(mm) | Tolerance(mm)(+1.5mm) | H6(mm) | Tolerance(mm)(+1.5mm) |

| 3.2 | +0.3 | 1.5 | ±0.15 | 0.5 | ±0.1 | 3.0 | 330 |

| 4.2 | +0.3 | 2.0 | ±0.2 | 0.6 | ±0.1 | 4.0 | 330 |

| 5.2 | +0.3 | 2.6 | ±0.2 | 0.8 | ±0.1 | 5.0 | 330 |

| 6.2 | +0.4 | 3.0 | ±0.2 | 0.9 | ±0.1 | 6.0 | 330 |

| 7.2 | +0.4 | 3.2 | ±0.2 | 1.0 | ±0.15 | 7.0 | 330 |

| 8.2 | +0.4 | 3.5 | ±0.2 | 1.2 | ±0.15 | 8.0 | 330 |

| 9.2 | +0.4 | 3.7 | ±0.3 | 1.4 | ±0.15 | 9.0 | 330 |

| 10.2 | +0.4 | 4.3 | ±0.3 | 1.6 | ±0.15 | 10.0 | 330 |

| 11.2 | +0.4 | 4.8 | ±0.4 | 1.5 | ±0.15 | 11.0 | 330 |

| 12.2 | +0.4 | 5.0 | ±0.4 | 1.8 | ±0.15 | 12.0 | 330 |

| 13.2 | +0.4 | 5.5 | ±0.5 | 1.8 | ±0.25 | 13.0 | 330 |

| 14.2 | +0.5 | 5.5 | ±0.5 | 1.8 | ±0.25 | 14.0 | 330 |

| 15.2 | +0.5 | 5.5 | ±0.5 | 1.8 | ±0.25 | 15.0 | 330 |

| 16.2 | +0.5 | 5.5 | ±0.5 | 1.8 | ±0.25 | 16.0 | 330 |

| 17.2 | +0.5 | 6.0 | ±0.5 | 2.0 | ±0.25 | 17.0 | 330 |

| 18.2 | +0.5 | 6.0 | ±0.5 | 2.0 | ±0.3 | 18.0 | 330 |

| 19.2 | +0.5 | 6.0 | ±0.5 | 2.0 | ±0.3 | 19.0 | 330 |

| 20.2 | +0.5 | 6.0 | ±0.5 | 2.0 | ±0.3 | 20.0 | 330 |

| 21.2 | +0.6 | – | ±0.6 | – | ±0.3 | 21.0 | 330 |

| 22.2 | +0.6 | – | ±0.6 | – | ±0.3 | 22.0 | 330 |

| 23.2 | +0.6 | – | ±0.6 | – | ±0.3 | 23.0 | 330 |

| 24.2 | +0.6 | – | ±0.6 | – | ±0.3 | 24.0 | 330 |

| 25.2 | +0.6 | – | ±0.6 | – | ±0.3 | 25.0 | 330 |

| 26.2 | +0.7 | – | ±0.7 | – | ±0.4 | 26.0 | 330 |

| 27.2 | +0.7 | – | ±0.7 | – | ±0.4 | 27.0 | 330 |

| 28.2 | +0.7 | – | ±0.7 | – | ±0.4 | 28.0 | 330 |

| 29.2 | +0.7 | – | ±0.7 | – | ±0.4 | 29.0 | 330 |

| 30.2 | +0.7 | – | ±0.7 | – | ±0.4 | 30.0 | 330 |

| 31.2 | +0.7 | – | ±0.7 | – | ±0.4 | 31.0 | 330 |

| 32.2 | +0.7 | – | ±0.7 | – | ±0.4 | 32.0 | 330 |

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options