SNMX insert

Are you looking for a reliable and efficient solution for your heavy-duty milling needs? Introducing SNMX inserts, the cutting-edge tool designed to handle the toughest machining tasks with ease. Whether you’re working with hardened steel or high-strength alloys, our SNMX inserts offer unparalleled performance and durability.

Specification Guide

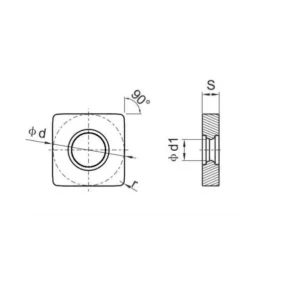

Shape and Geometry:

- Inserts typically have a square shape with negative rake angles, providing robust cutting edges.

- The design often includes multiple cutting edges, allowing for extended tool life by rotating the insert to use different edges.

Thickness:

- These inserts are generally thicker, providing enhanced strength and durability, which is crucial for handling heavy cutting forces.

Coating and Material:

- Inserts are available in various grades and coatings, such as PVD and CVD, to enhance wear resistance and cutting performance in different materials.

Applications

Heavy-Duty Milling:

- SNMX inserts are ideal for heavy-duty milling operations where high material removal rates are required. Their robust design allows them to withstand high cutting forces and temperatures.

Roughing Operations:

- These inserts are commonly used in roughing operations to remove large amounts of material quickly and efficiently.

Hard Materials:

- SNMX inserts are suitable for machining hard and tough materials, such as hardened steel and high-strength alloys, due to their strength and durability.

Interrupted Cuts:

- Their robust design makes SNMX inserts well-suited for operations involving interrupted cuts, where the cutting tool repeatedly enters and exits the material.

Why Choose SNMX Inserts?

Superior Durability and Strength

Our SNMX inserts are engineered with a thicker and stronger design, providing exceptional durability. This ensures that they can withstand high cutting forces and temperatures, making them ideal for demanding milling operations.

Multiple Cutting Edges

Maximize your tool life with SNMX inserts that feature multiple cutting edges. By rotating the insert, you can utilize each edge, significantly reducing the cost per cutting edge and increasing overall efficiency.

Versatile Applications

SNMX inserts are perfect for a variety of milling tasks:

- Heavy-Duty Milling: Achieve high material removal rates with ease.

- Roughing Operations: Quickly remove large amounts of material.

- Machining Hard Materials: Ideal for hardened steel and high-strength alloys.

- Interrupted Cuts: Reliable performance in challenging conditions.

Advanced Coatings and Materials

Choose from a range of grades and coatings, such as PVD and CVD, to enhance wear resistance and cutting performance. Our SNMX inserts are tailored to meet the specific needs of your applications, ensuring optimal results every time.

Benifit of Your Milling Inserts

Elevate Your Milling Performance

Imagine the increased productivity and cost savings you'll achieve with SNMX inserts. Our high-performance inserts not only improve your milling operations but also extend tool life, reducing downtime and increasing profitability.

Proven Performance

Join the numerous satisfied customers who have transformed their milling operations with SNMX inserts. Our inserts are trusted by industry leaders for their reliability and superior cutting performance.

Custom Solutions

We understand that every business has unique needs. That’s why we offer custom solutions tailored to your specific milling requirements. Our team of experts is here to help you choose the right inserts and provide ongoing support to ensure your success.

Frequently Asked Questions

What are SNMX inserts?

Inserts are a type of indexable cutting tool insert designed for heavy-duty milling operations. They feature a square shape, negative rake angles, and multiple cutting edges, providing robust performance and extended tool life.

How many cutting edges do inserts have?

Inserts typically have four cutting edges. This design allows for the rotation of the insert to use each edge, maximizing tool life and reducing overall costs.

What types of coatings are available for inserts?

SNMX inserts are available with various coatings to enhance performance and durability, including: PVD (Physical Vapor Deposition) coatings for improved wear resistance and reduced friction CVD (Chemical Vapor Deposition) coatings for enhanced toughness and longer tool life

What applications are inserts best suited for?

SNMX inserts are ideal for: Heavy-duty milling operations Roughing operations Machining hard materials, such as hardened steel and high-strength alloys Operations involving interrupted cuts

What materials can inserts machine effectively?

Inserts can machine a variety of materials, including: Hardened steel High-strength alloys Cast iron Stainless steel Non-ferrous metals (e.g., aluminum and copper)

How do I choose the right insert for my application?

Choosing the right SNMX insert involves considering: The material to be machined The specific milling operation (roughing or finishing) Desired surface finish Cutting conditions (speed, feed, depth of cut) The type of machine and holder being used Consulting with a tooling expert from [Your Company Name] can help ensure the best selection for your needs.

Our Production Capability