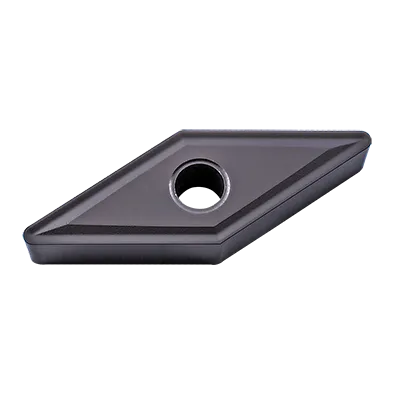

VNMG insert

VNMG insert Angle :35 Degree 0° Negative Rake Insert with double-sided Chipbreaker;

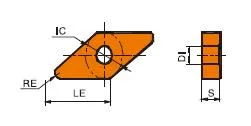

Dimensions: IC:9.525mm;LE:11mm/16.6mm;RE0.4mm/0.8mm/1.2mm;

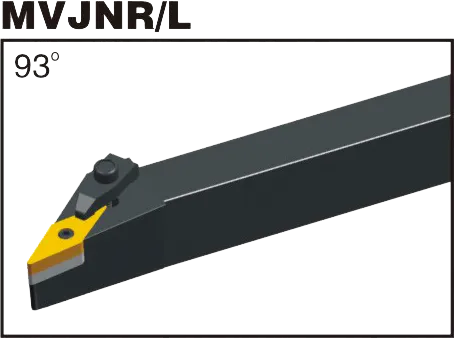

Matching VNMG Insert Holder: MVVNN, MVJNR/L;

VNMG insert sizes:(ISO) VNMG 12t304/VNMG160402/ VNMG160404/ VNMG160408;

(ANSI) VNMG330/ VNMG330.5/ VNMG331/ VNMG332/ VNMG431/ VNMG432;

It can deal with multiple operations by combining different chip breakers and grades;

Product Introduction

VNMG Insert is made of high quality alloy metal with advanced technology.

The surface is treated with special coating to extend the using life.

The unique V shape design with negative angles of the VNMG Insert guarantees efficient machining and high stability.

The combination of different chip breakers and grades will help it to deal with different working condition and multiple operations.

In addition, it has the advantages of high hardness, high efficiency, high accuracy, corrosion resistance, long service life, smooth appearance as well as high quality.

Key Features

- Shape: VNMG inserts are triangular with a 35° included angle, providing a good balance between strength and sharpness. This shape offers three usable cutting edges.

- Negative Rake Angle: The cutting face slopes backward from the cutting edge, providing a strong, durable edge well-suited for tougher materials and interrupted cuts.

- Clearance Angle: Typically 7° to help prevent rubbing against the workpiece.

- Chipbreakers: VNMG inserts often feature chipbreaker geometries to control chip formation and flow during machining, tailored to specific applications.

- Coatings: Often coated with materials like TiN, AlTiN, and others to improve wear resistance and tool life.

VNMG insert Specification

Understanding the VNMG Code

The letters and numbers in the VNMG designation signify important details:

- V: 35° rhombic (diamond) shape

- N: Negative rake angle

- M: Tolerance class (indicates precision of the size)

- G: Indicates hole type and chipbreaker design (varies by manufacturer)

- Numbers:

- Usually, the first two numbers represent the inscribed circle (size of the triangle) in sixteenths of an inch (or directly in millimeters for ISO codes).

- The third number represents thickness in sixteenths of an inch.

- The last number often indicates the nose radius (smaller means sharper).

VNMG insert holder

Carbide VNMG Insert Dimensions (ISO AND ANSI)

| vnmg insert full form | ||||

|---|---|---|---|---|

| ISO Designation | ANSI Designation | Inscribed Circle (IC) | Thickness | Corner Radius |

| VNMG 160404 | VNMG331 | 16mm (0.63") | 4.76mm (0.187") | 0.4mm (0.016") |

| VNMG 160408 | VNMG332 | 16mm (0.63") | 4.76mm (0.187") | 0.8mm (0.031") |

| VNMG 160412 | VNMG333 | 16mm (0.64") | 4.76mm (0.188") | 1.2MM(0.047'') |

Example: VNMG 160408 (ISO)

- 35° triangular shape, negative rake insert.

- Inscribed circle of 12.7mm (approx. 1/2″).

- Thickness of 4.76mm (approx. 3/16″).

- Specific chipbreaker/hole design.

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

Carbide inserts are some of the most versatile and durable cutting tools available. But how are they made? And what makes them so strong? In this video, we’ll explore the science behind carbide inserts, from the properties of tungsten carbide to the manufacturing process.

Our Production Capability

In modern manufacturing, high-performance carbide inserts are indispensable tools, laying the foundation for efficient and precise metal processing. However, these exceptional inserts do not come into existence on their own; they are supported by the unwavering support of advanced machinery.