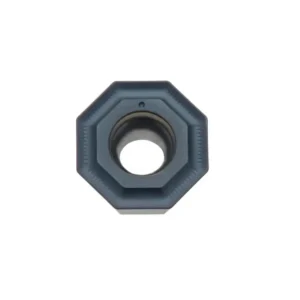

ODMT insert

Are you struggling with inconsistent machining results or high tooling costs? ODMT are the game-changing solution that industry leaders trust. These versatile, high-performance cutting tools are designed to tackle your toughest machining challenges.

Why ODMT Inserts Are Transforming the Machining Industry

- Unmatched versatility for various materials and operations

- Superior edge strength for extended tool life

- Precision-engineered for optimal chip control

- Cost-effective solution for high-volume production

The Insert Advantage: Boosting Your Bottom Line

- Reduce machining time by up to 30%

- Decrease tooling costs with longer-lasting inserts

- Achieve superior surface finishes consistently

- Minimize downtime with quick and easy indexing

Choosing the Right Insert for Your Application

- Overview of ODMT insert grades and coatings

- Matching inserts to specific materials and operations

- Tips for optimizing cutting parameters

Implementation and Support: Your Path to Success

- Free consultation with our machining experts

- Customized solution packages for your specific needs

- Comprehensive training and ongoing technical support

- 30-day satisfaction guarantee

Frequently Asked Questions

What does ODMT stand for in machining inserts?

ODMT stands for Octagonal Double-sided Milling Tool. This designation refers to the insert's octagonal shape and its ability to be used on both sides, effectively doubling its usable cutting edges.

What materials can be machined with ODMT inserts?

Steel and stainless steel Cast iron Aluminum and other non-ferrous metals Certain high-temperature alloys

Can ODMT inserts be used for high-speed machining?

Yes, many ODMT inserts are designed for high-speed machining applications. However, it's crucial to choose the right grade and coating for your specific high-speed requirements and ensure your machine tool is capable of the necessary speeds and feeds.

What types of milling operations are ODMT inserts best suited for?

Face milling Shoulder milling Profiling Slotting High-feed milling (depending on the specific insert design)

How do ODMT inserts compare to other insert shapes?

ODMT inserts offer a balance between the stability of square inserts and the versatility of round inserts. Their octagonal shape provides multiple cutting edges while maintaining good stability, making them suitable for various milling operations.

Are ODMT inserts more expensive than other insert types?

While the initial cost of ODMT inserts may be slightly higher than some simpler insert shapes, their multiple cutting edges and double-sided design often result in lower cost per edge, making them cost-effective in the long run, especially for high-volume production.

Our Production Capability