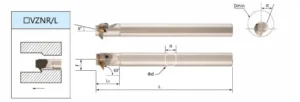

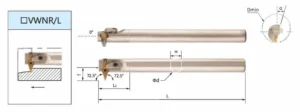

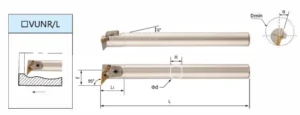

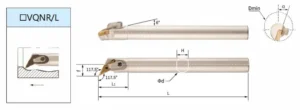

VNMG Insert Holder

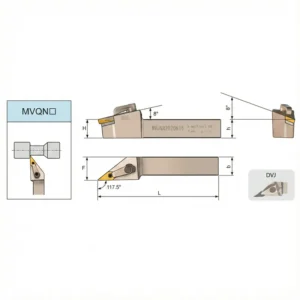

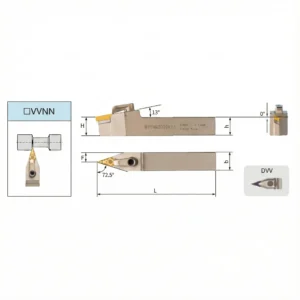

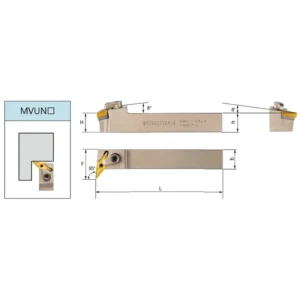

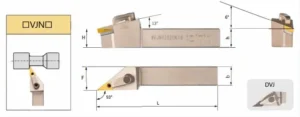

A VNMG Insert Holder is a specialized turning tool holder designed to securely clamp VNMG style indexable cutting inserts. The ISO designation “VNMG” signifies a V-shaped insert with a 35-degree nose angle, a clearance angle, neutral cutting action, and a central mounting hole. These inserts are particularly well-suited for finishing and semi-finishing operations, as well as profiling and applications requiring good access due to their acute angle. They are commonly used on a variety of materials, including steel, stainless steel, aluminum, and non-ferrous metals.

The primary function of a VNMG Insert Holder is to provide a stable and precisely oriented platform for the VNMG insert. This ensures accurate material removal, excellent surface finishes, and the ability to create intricate part geometries. The holder features a precision-machined pocket that conforms to the specific shape and dimensions of the VNMG insert, allowing for secure and repeatable clamping, typically achieved with a screw or lever mechanism. This robust clamping prevents insert movement and vibration during machining, which is crucial for achieving high-quality results, especially in finishing passes.

VNMG inserts are favored for their ability to produce fine finishes and their suitability for creating complex contours. They offer two cutting edges per side, totaling four usable edges per insert, providing good tool life and cost-effectiveness. The corresponding VNMG Insert Holders are designed for ease of use, enabling quick and efficient insert changes, thus minimizing machine downtime. Available in various shank sizes and configurations to fit different machine tool types and application needs, VNMG Insert Tool Holders are a valuable asset in precision machining environments.

Frequently Asked Questions

“VNMG” is an ISO designation for a V-shaped cutting insert with a 35-degree nose angle and specific features.

It holds VNMG style indexable cutting inserts, which are V-shaped with a 35-degree nose angle.

Finishing and semi-finishing operations, profiling, and applications requiring good access and reduced cutting forces.

Excellent for achieving fine surface finishes, good for profiling intricate shapes, reduced cutting forces due to the 35-degree angle.

Consider the shank size needed for your machine, the type of operation (finishing, profiling), the workpiece material, and the required lead angle.

Common sizes include 1/2″, 5/8″, 3/4″, 1″, and metric equivalents, to fit various machine tool holders.

While possible for light roughing, their geometry is generally better suited for finishing and semi-finishing due to the sharper included angle.

High precision in the insert pocket, secure and reliable clamping, good build quality for stability, and compatibility with your machine and VNMG inserts.

Yes, holders are available with various lead angles to optimize cutting performance for different profiling and finishing tasks.

Contact Us for Your Tool Holders

Please note: We are a wholesale supplier and have minimum order quantities.