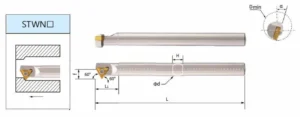

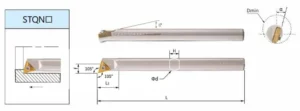

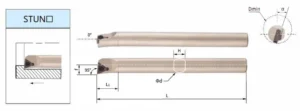

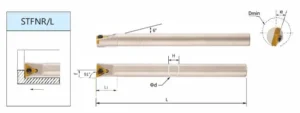

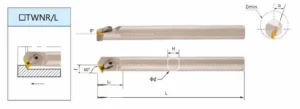

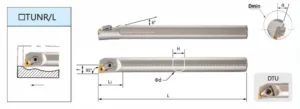

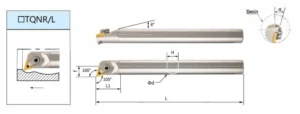

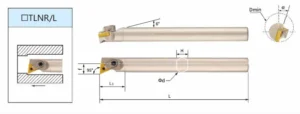

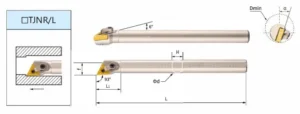

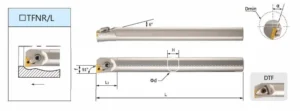

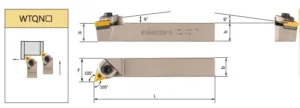

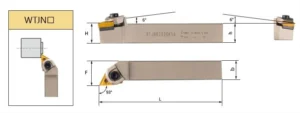

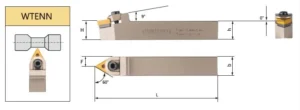

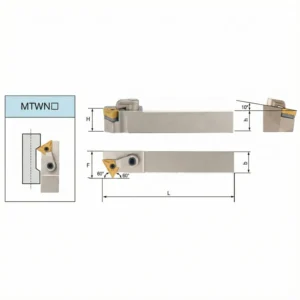

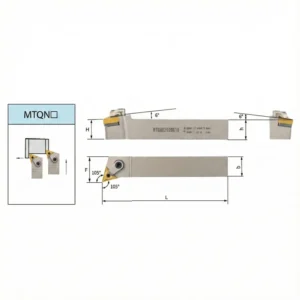

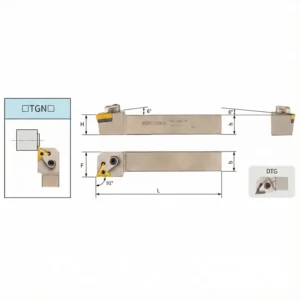

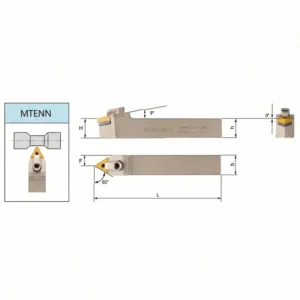

TNMG Insert Holder

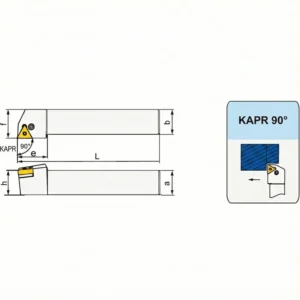

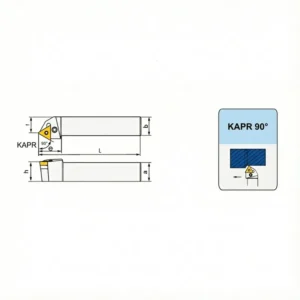

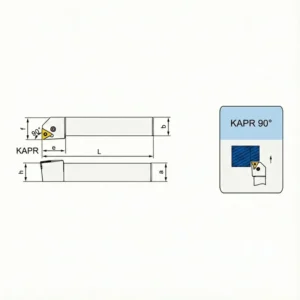

A TNMG Insert Holder is a specific type of turning tool holder designed to securely clamp TNMG style indexable cutting inserts. The “TNMG” designation refers to the ISO standard for a triangular-shaped insert with a 60-degree nose angle, neutral cutting action, and a hole for secure mounting. These inserts are commonly used for a wide range of turning operations, including roughing, semi-finishing, and finishing of various materials.

The primary function of a TNMG Insert Holder is to provide a rigid and stable platform for the TNMG insert, ensuring accurate material removal and a good surface finish. The holder is designed with a specific pocket that precisely matches the shape and dimensions of the TNMG insert, allowing for secure clamping and proper cutting geometry. The clamping mechanism, often utilizing a screw or lever, ensures the insert remains firmly in place during machining, even under significant cutting forces.

TNMG inserts are popular due to their versatility, offering three cutting edges per insert, which can be indexed as one edge wears out, providing cost-effectiveness and extended tool life. The corresponding TNMG Insert Holders are engineered for ease of use, allowing for quick and efficient insert changes, minimizing downtime in machining processes. These holders are available in various shank sizes and styles to fit different machine tool holders and are a staple in many turning applications across diverse industries.

Frequently Asked Questions

“TNMG” is an ISO designation for a triangular-shaped cutting insert with specific features.

It holds TNMG style indexable cutting inserts, which are triangular with a 60-degree nose angle.

A wide range of turning operations, including roughing, semi-finishing, and finishing on various materials.

Consider the shank size needed for your machine, the type of turning operation, and the material you are machining.

Common sizes include 1/2″, 5/8″, 3/4″, 1″, and metric equivalents, to fit various machine tool holders.

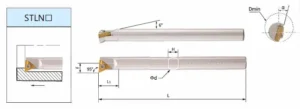

While primarily used for external turning, some specialized TNMG insert holders might be adapted for certain internal turning operations, but dedicated internal turning holders are usually preferred.

Rigidity, secure clamping mechanism, good build quality, and compatibility with your machine and inserts.

Yes, holders are available with various lead angles to optimize cutting performance for different turning applications.

Contact Us for Your Tool Holders

Please note: We are a wholesale supplier and have minimum order quantities.