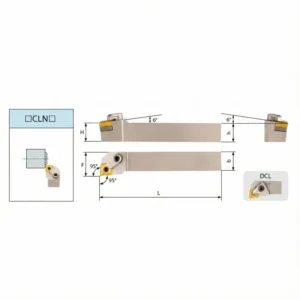

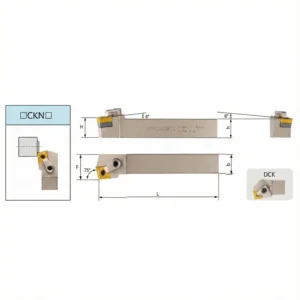

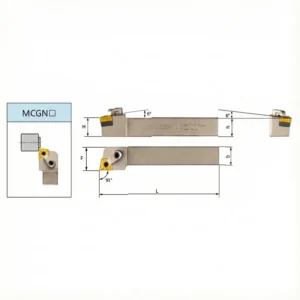

CNMG Insert Tool Holder

A CNMG Insert Tool Holder is a widely used type of turning tool holder specifically designed to securely clamp CNMG style indexable cutting inserts. The “CNMG” designation, according to ISO standards, refers to a rhombic-shaped insert with an 80-degree nose angle, a clearance angle, neutral cutting action, and a central mounting hole. These inserts are highly versatile and are commonly employed for medium to heavy-duty roughing and semi-finishing operations on a broad range of materials, including steel, stainless steel, and cast iron.

The primary function of a CNMG Insert Tool Holder is to provide a robust and stable platform for the CNMG insert. This ensures accurate material removal rates, good chip control, and optimal surface finishes. The holder features a precision-machined pocket that matches the exact shape and dimensions of the CNMG insert, allowing for secure and repeatable clamping. Typically, a screw or lever mechanism is used to firmly hold the insert in place, preventing any unwanted movement or vibration during machining, even under substantial cutting forces.

CNMG inserts are popular due to their strong cutting edges and the availability of four cutting edges per insert (two on each side), offering excellent tool life and cost-effectiveness. The corresponding CNMG Insert Tool Holders are designed for ease of use, facilitating quick and efficient insert indexing or replacement, thereby minimizing machine downtime. These holders are available in various shank sizes and configurations to suit different machine tool types and machining applications. When selecting a CNMG Insert Tool Holder, considering the required cnmg insert tool holder specification such as shank size and lead angle is crucial for optimal performance.

Frequently Asked Questions

“CNMG” is an ISO designation indicating a specific rhombic (80-degree) shaped cutting insert with a clearance angle and neutral cutting action.

It holds CNMG style indexable cutting inserts, which are rhombic with an 80-degree nose angle.

Medium to heavy-duty roughing and semi-finishing operations on a wide range of materials.

Strong cutting edges, four cutting edges per insert, good chip control, versatile for various materials.

Consider the shank size needed for your machine, the type of turning operation, the material you are machining, and the required lead angle. Checking the cnmg insert tool holder specification is important here.

Common sizes include 1/2″, 5/8″, 3/4″, 1″, and metric equivalents, to fit various machine tool holders.

Yes, with the appropriate CNMG insert grade and geometry, it can be used for semi-finishing and even some finishing applications.

Rigidity, secure clamping, precise insert pocket, and compatibility with your machine and inserts. Reviewing the cnmg insert tool holder specification will help.

Yes, holders are available with various lead angles to optimize performance for different turning tasks.

cnmg insert tool holder specification

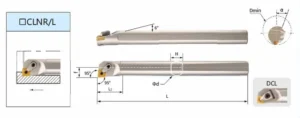

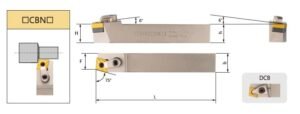

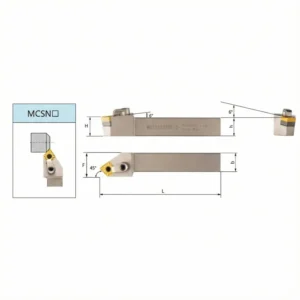

- Shank Size (System Designation): This refers to the dimensions of the tool holder’s shank that fits into the machine tool’s turret or tool post. Common shank sizes are given in inches (e.g., 1/2″, 5/8″, 3/4″, 1″) or millimeters (e.g., 12mm, 16mm, 20mm, 25mm). This is crucial for compatibility with your machine.

- Overall Length: The total length of the tool holder, which can be important for clearance and reach in certain machining setups.

- Insert Size Designation: Specifies the exact size and geometry of the CNMG insert that the holder is designed to accommodate. For example, you might see specifications like “for CNMG120404”, where “12” refers to the cutting edge length, “04” to the thickness, and “04” to the nose radius (in this example, following a common interpretation). Different CNMG insert sizes will require different tool holders.

- Lead Angle (Cutting Edge Angle): This is the angle between the cutting edge of the insert and the direction of feed. Different lead angles are suitable for various turning operations, such as facing, shouldering, or general turning. Common lead angles for CNMG holders might be 0 degrees, 5 degrees, or others.

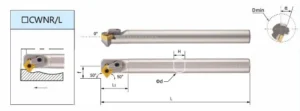

- Cutting Direction (Hand): Indicates whether the tool holder is designed for right-hand or left-hand cutting. This determines the direction in which the tool can be fed along the workpiece.

- Coolant Supply: Specifies whether the tool holder has internal coolant channels that direct coolant to the cutting zone. This is beneficial for chip evacuation, reducing cutting temperatures, and improving tool life. You might see designations like “with internal coolant” or “without internal coolant.”

- Clamping System: Describes the method used to secure the CNMG insert in the holder. Common clamping systems include screw-on, lever lock, or wedge clamp.

- Tool Style/Designation: Manufacturers often have their own specific coding systems or model numbers that further define the tool holder’s characteristics and intended use.

- Material: The material from which the tool holder is made, typically a high-strength alloy steel for durability and rigidity.

- Coating: Some tool holders may have surface coatings to enhance wear resistance, reduce friction, or improve performance in specific materials.

- Manufacturer: The company that produces the tool holder.

Contact Us for Your Tool Holders

Please note: We are a wholesale supplier and have minimum order quantities.