TIPS & TRICKS

To achieve perfect results in production, you need powerful tools. for more than 15 years, our customers have been benefiting from our products to efficiently carry out machining work, especially metal cutting with high-quality precision tools.

Please find here troubleshooting solutions or tips on how to optimize your machining processes. In this section, we provide you with tips and tricks for the safe use and therefore longer lifetime of your tools.

Have you tried everything but your machining processes are not yet as optimized as you would like? Need our expert advice?

We are happy to support you! Contact our experts:

- +86-15050255160

- bigsunjiang@gmail.com

- +86-15050255160

- Inquiry

SOLID CARBIDE DRILL

TYPES OF WEAR

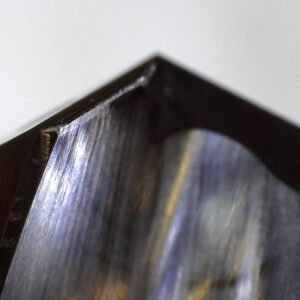

Flank wear

Action

- Reduce cutting speed

- Increase coolant pressure / quantity

- Increase the concentration of the cooling lubricant

- Increase feed rate

TYPES OF WEAR

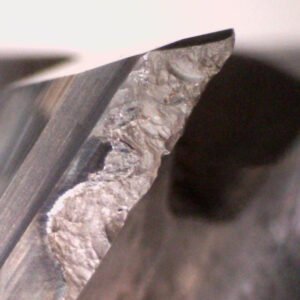

Crater wear

Action

- Reduce cutting speed

- Increase coolant pressure / quantity

- Increase the concentration of the cooling lubricant

- Reduce feed rate

TYPES OF WEAR

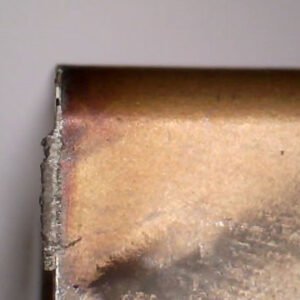

Plastic deformation

Action

- Reduce cutting speed

- Increase coolant pressure / quantity

- Increase the concentration of the cooling lubricant

- Reduce feed rate

TYPES OF WEAR

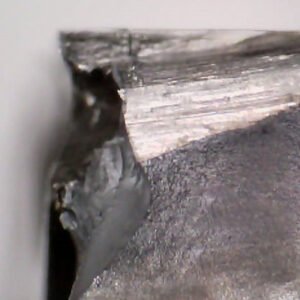

Bulit-up edge

Action

- Increase cutting speed

- Increase coolant pressure / quantity

- Increase the concentration of the cooling lubricant

- Increase feed rate

TYPES OF WEAR

Cut chisel edge splintering

Action

- Increase cutting speed

- Increase coolant pressure / quantity

- Reduce feed rate

- Check concentricity

INDEXABLE INSERT DRILLS

TYPES OF WEAR

Flank wear

Action

- Reduce cutting speed

- Increase coolant pressure / quantity

- Increase the concentration of the cooling lubricant

- Increase feed rate

TYPES OF WEAR

Crater wear

Action

- Reduce cutting speed

- Increase coolant pressure / quantity

- Increase the concentration of the cooling lubricant

- Reduce feed rate

TYPES OF WEAR

Plastic deformation

Action

- Reduce cutting speed

- Increase coolant pressure / quantity

- Increase the concentration of the cooling lubricant

- Reduce feed rate

TYPES OF WEAR

Bulit-up edge

Action

- Increase cutting speed

- Increase coolant pressure / quantity

- Increase the concentration of the cooling lubricant

- Increase feed rate

TYPES OF WEAR

Cutting edge breakage

Action

- Increase cutting speed

- Increase coolant pressure / quantity

- Reduce feed rate

TYPES OF WEAR

Edge cracking

Action

- Reduce cutting speed

- Increase coolant pressure / quantity

- Increase the concentration of the cooling lubricant

- Reduce feed rate

TYPES OF WEAR

Breakouts

Action

- Increase cutting speed

- Increase coolant pressure / quantity

- Increase the concentration of the cooling lubricant

- Reduce feed rate

SOLID CARBIDE END MILLS

TYPES OF WEAR

Flank wear

Action

- Reduce cutting speed

- Check cooling jet direction / use holder with IC

- Increase feed rate

TYPES OF WEAR

Crater wear

Action

- Reduce cutting speed

- Check cooling jet direction / use holder with IC

- Increase feed rate

TYPES OF WEAR

Notch wear

Action

- Reduce cutting speed

- Check cooling jet direction / use holder with IC

- Increase feed rate

TYPES OF WEAR

Bulit-up edge

Action

- Increase cutting speed

- Check cooling jet direction / use holder with IC

- Work without cooling lubrication

- Increase feed rate

TYPES OF WEAR

Cutting edge breakage

Action

- Reduce feed rate

TYPES OF WEAR

Edge cracking

Action

- Reduce cutting speed

- Work without cooling lubrication

- Reduce feed rate

TYPES OF WEAR

Breakouts

Action

- Increase cutting speed

- Check cooling jet direction / use holder with IC

- Reduce feed rate

INDEXABLE INSERT MILLS

TYPES OF WEAR

Flank wear

Action

- Reduce cutting speed

- Use a harder carbide grade

- Check cooling jet direction / use mill with IC

- Increase feed rate

TYPES OF WEAR

Crater wear

Action

- Reduce cutting speed

- Use a harder carbide grade

- Check cooling jet direction / use mill with IC

- Reduce feed rate

- Use suitable insert geometry (ap / fn)

TYPES OF WEAR

Notch wear

Action

- Reduce cutting speed

- Use a softer carbide grade

- Reduce feed rate

- Use a harder smaller setting angle

- Use suitable insert geometry (ap / fn)

TYPES OF WEAR

Plastic deformation

Action

- Reduce cutting speed

- Use a harder carbide grade

- Check cooling jet direction / use mill with IC

- Reduce feed rate

- Use a harder smaller setting angle

- Use suitable insert geometry (ap / fn)

TYPES OF WEAR

Bulit-up edge

Action

- Increase cutting speed

- Check cooling jet direction / use mill with IC

- Work without cooling lubrication

- Increase feed rate

- Use suitable insert geometry (ap / fn)

TYPES OF WEAR

Cutting edge breakage

Action

- Use a softer carbide grade

- Reduce feed rate

- Use a harder smaller setting angle

- Use suitable insert geometry (ap / fn)

TYPES OF WEAR

Edge cracking

Action

- Reduce cutting speed

- Use a softer carbide grade

- Work without cooling lubrication

- Reduce feed rate

TYPES OF WEAR

Breakouts

Action

- Increase cutting speed

- Use a softer carbide grade

- Check cooling jet direction / use holder with IC

- Reduce feed rate

- Use a harder smaller setting angle

- Use suitable insert geometry (ap / fn)

TURNING INSERTS

TYPES OF WEAR

Flank wear

Action

- Reduce cutting speed

- Use a harder carbide grade

- Check cooling jet direction / use holder with IC

- Increase feed rate

TYPES OF WEAR

Crater wear

Action

- Reduce cutting speed

- Use a harder carbide grade

- Check cooling jet direction / use holder with IC

- Reduce feed rate

- Use suitable insert geometry (ap / fn)

TYPES OF WEAR

Notch wear

Action

- Reduce cutting speed

- Use a softer carbide grade

- Reduce feed rate

- Use a harder smaller setting angle

- Use suitable insert geometry (ap / fn)

TYPES OF WEAR

Plastic deformation

Action

- Reduce cutting speed

- Use a harder carbide grade

- Check cooling jet direction / use holder with IC

- Reduce feed rate

- Use suitable insert geometry (ap / fn)

TYPES OF WEAR

Bulit-up edge

Action

- Increase cutting speed

- Check cooling jet direction / use holder with IC

- Increase feed rate

- Use suitable insert geometry (ap / fn)

TYPES OF WEAR

Cutting edge breakage

Action

- Reduce cutting speed

- Use a softer carbide grade

- Reduce feed rate

- Use a harder smaller setting angle

- Use suitable insert geometry (ap / fn)

TYPES OF WEAR

Edge cracking

Action

- Reduce cutting speed

- Use a softer carbide grade

- Work without cooling lubrication

- Reduce feed rate

TYPES OF WEAR

Breakouts

Action

- Increase cutting speed

- Use a softer carbide grade

- Check cooling jet direction / use holder with IC

- Reduce feed rate

- Use a harder smaller setting angle

- Use suitable insert geometry (ap / fn)