Ideal for: High-Pressure Gas Wells, Premium Tubing Connections, Deep Water Drilling.

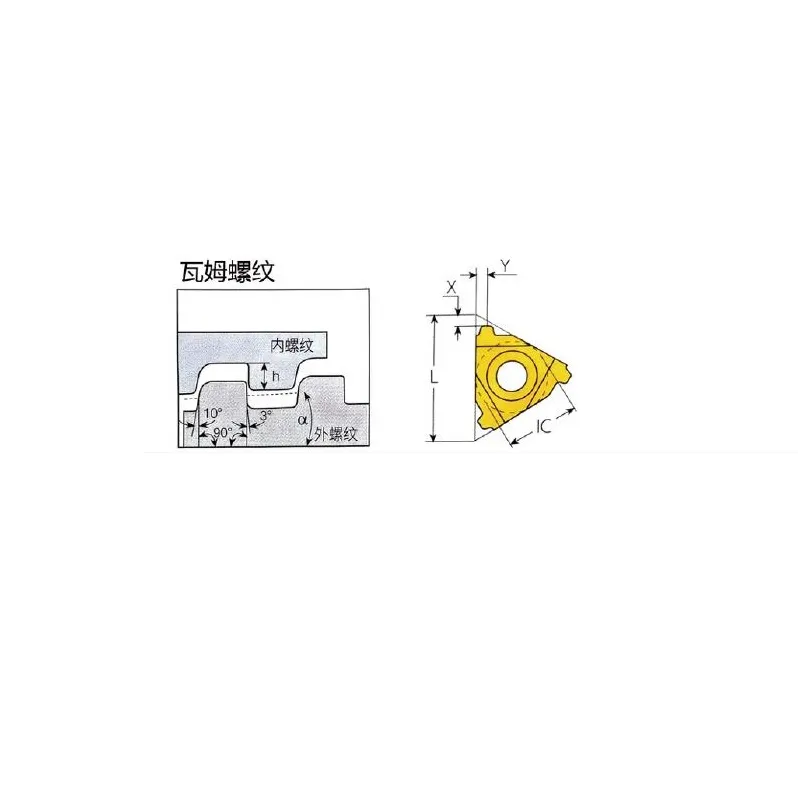

- Product Standard: VAM Premium Connection laydown threading inserts.

- Gas-Tight Seal: Engineered for premium “Metal-to-Metal” seal connections, offering superior leak resistance compared to standard API Round threads.

- Pitch Options: Specific coverage for 8 TPI (Tubing) and heavy-duty 6 TPI / 5 TPI (Casing) profiles.

- Core Availability: Stocked in the popular 16er threading insert (3/8″ I.C.) and robust 1/2″ (22mm) I.C. sizes.

- Versatility: High-performance threading inserts for lathe applications, available in Right-Hand and left hand thread insert models.

-

Material: Specialized carbide threading inserts grade optimized for high-tensile, heat-treated oilfield alloys.

Contact our sales team to discover all of your pricing options.

Product Overview

Manufacture high-integrity premium connections with our VAM style laydown threading inserts. Unlike standard API connections that rely on thread compound for sealing, VAM connections utilize a sophisticated thread profile to achieve a gas-tight metal-to-metal seal, making them essential for critical high-pressure and sour service (H2S) environments.

These carbide threading inserts are precision ground to maintain the exact thread form, taper, and lead required for VAM specifications. The profile prevents galling during make-up while ensuring the structural integrity of the joint under extreme tension and compression.

Key Features & Benefits

- Premium Performance: Designed for critical downhole applications where standard API threads may fail.

- The 16ER Standard: Our 16er threading inserts (16ER 8 VAM) are the industry standard for threading premium tubing strings.

- Heavy Duty Casing: For larger casing requirements, our 22ER (Size 22) inserts handle coarse 6 TPI and 5 TPI pitches with maximum rigidity.

-

Directional Options: We offer comprehensive solutions, including standard right-hand tools and specialized left hand thread insert models (e.g., 16EL 8 VAM) for specific string accessories.

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options