- The side screw lock allows for quick installation without disassembling the entire unit.

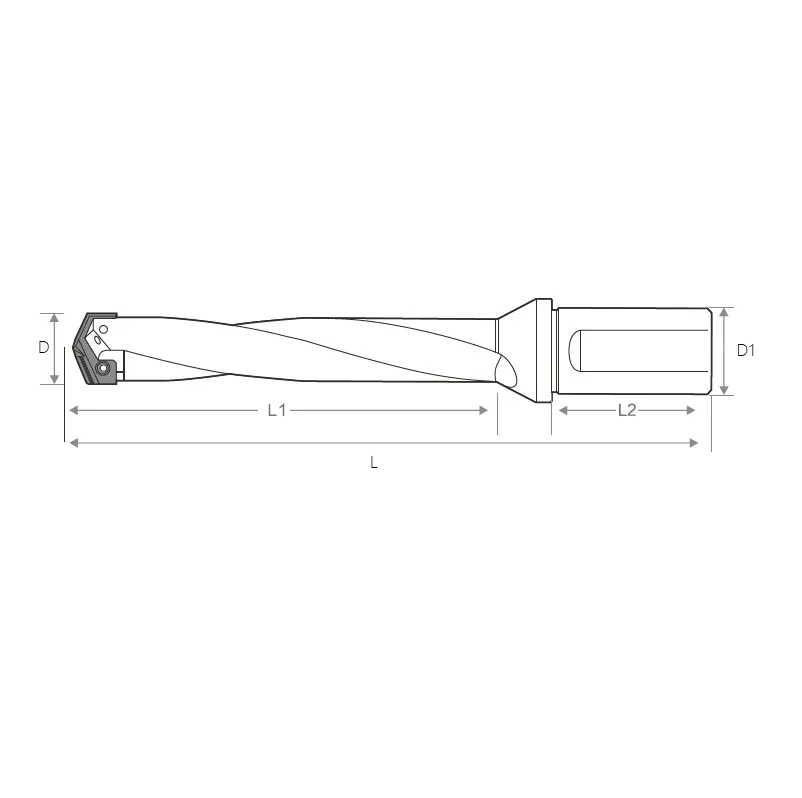

- 3D toolholder.

- For general steel processing.

- D10-D25 available.

Contact our sales team to discover all of your pricing options.

- Robust Construction: Typically made from high-strength tool steel or hardened alloys, the drill body is engineered for durability, rigidity, and resistance to vibration during high-speed machining.

- Side Locking Mechanism: Features a side-mounted set screw, pin, or clamp system to securely lock the replaceable insert in place, ensuring precise alignment and preventing tip movement during drilling.

- Modular Compatibility: Designed to accommodate a range of insert sizes and geometries, allowing a single drill body to support multiple hole diameters and material-specific tips, reducing tool inventory needs.

- Internal Coolant Channels: Many drill bodies include through-coolant passages that deliver high-pressure coolant (recommended minimum 200 psi) directly to the cutting zone, enhancing chip evacuation, reducing heat, and extending insert life.

- Optimized Flute Design: Incorporates polished or helical flutes for efficient chip removal, minimizing clogging and improving surface finish, especially in deep-hole drilling applications.

- High Precision Mounting: The body ensures accurate insert positioning, often achieving tolerances within ±0.0005″ (0.013 mm) or IT9-IT11 standards, critical for precision machining in industries like aerospace and automotive.

- Shank Versatility: Available with various shank types (e.g., straight, Morse taper, or modular systems like HSK or CAT), ensuring compatibility with a wide range of CNC machines and toolholders.

- Durability and Reusability: The drill body is designed for repeated use across multiple insert changes, offering a cost-effective solution compared to solid carbide drills, as only the insert needs replacement.

- Balanced Design: Engineered for high-speed stability, reducing runout and ensuring consistent performance, even in demanding applications like drilling tough materials such as stainless steel or super alloys.

- Application Flexibility: Suitable for diverse industries, including aerospace, automotive, and oil and gas, supporting high-volume production and a variety of materials from aluminum to exotic alloys.

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options