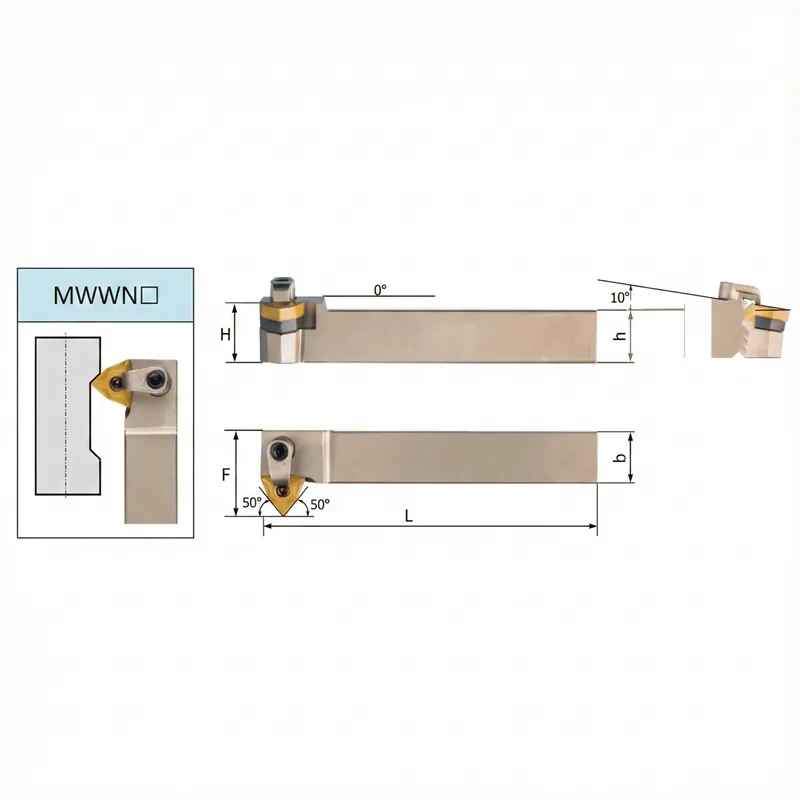

MWWNR Tool Holder with 50° Angle for High-Feed Turning

- Tool Type: External Turning Tool Holder (Directional: Right/Left)

- Model Series: MWWNR/L

- Entering Angle: 50° Entering Angle

- Clamping System: M-Type Double Clamp (Pin & Top Clamp)

- Insert Compatibility: WNMG, WNMA, WNMM (Trigon 80° Inserts)

-

Key Benefit: 6 cutting edges with a stable 50° angle for high feed rates.

Contact our sales team to discover all of your pricing options.

Overview

The MWWNR/L series is a specialized external turning tool holder designed for specific heavy-duty applications. Unlike standard 95° holders, the MWWNR features a robust 50° entering angle (40° lead angle). This geometry is engineered to direct cutting forces axially along the workpiece, reducing radial pressure and allowing for higher feed rates and deeper cuts in roughing operations.

Optimized for WNMG Inserts

This holder utilizes the economical WNMG insert (Trigon). By combining the 6 usable cutting edges of the WNMG insert with the stability of a 50° holder, machinists get the best of both worlds: low cost per edge and high metal removal rates. It is also the ideal tool for creating accurate 50° chamfers.

Rigid M-Type Stability

Cutting at a 50° angle generates significant forces. The MWWNR TOOL HOLDER employs the M-Type Double Clamping System. The lock pin and heavy-duty top clamp ensure the insert remains rigid, preventing movement even when the MWWNR 2525 is pushed to its limit on alloy steels or forgings.

ISO Code Naming Rules

Here is the breakdown of the MWWNR code, reflecting your specific 50° geometry:

| Position | Code | Parameter | Description & Technical Advantage |

| 1st | M | Clamping Method |

Multi-lock (Double Clamp): Uses pin & top clamp.

• Benefit: Essential for securing the insert during heavy roughing. |

| 2nd | W | Insert Shape |

Trigon (80°): Fits WNMG inserts.

• Benefit: Strong 80° corner with 6 usable cutting edges. |

| 3rd | W | Holder Style |

50° Entering Angle:

• Benefit: (Specific Manufacturer Design). Provides chip thinning effect for higher feed rates and specific chamfering. |

| 4th | N | Clearance Angle |

Negative (0°): Insert sits perpendicular.

• Benefit: Double-sided insert economy. |

| 5th | R/L | Hand of Tool |

Right (R) / Left (L): Direction of cut.

• Benefit: MWWNR is Right-hand, MWWNL is Left-hand. |

FAQs

Q1: What is the difference between MWWNR and MWMNN?

A: Both feature a 50° angle and use WNMG inserts. The difference is the “Hand”. MWMNN is a Neutral tool (Symmetric), ideal for bi-directional cutting. MWWNR is a Right-Hand tool (Directional), optimized for heavy cutting in one direction (towards the chuck).

Q2: Why use a 50° angle for roughing?

A: The 50° angle (40° lead) creates a “Chip Thinning” effect similar to a 45° cutter. It spreads the heat and load over a wider section of the insert edge, allowing you to run at higher feed rates than a 95° tool, boosting productivity.

Q3: Is the MWWNR 2525 suitable for facing?

A: It is not designed for facing to center. The 50° angle means it would leave a large uncut portion at the center of the part. It is best used for longitudinal roughing (OD Turning) and chamfering.

| MODEL | SIZE (MM) | INSERT | SCREW | WRENCH | WRENCH | PLATEN | DOUBLE SCREW | WRENCH | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LEFT | RIGHT | h | b | H | F | L | |||||||

| MWWNL2020K08 | MWWNR2020K08 | 20 | 20 | 20 | 32 | 125 | WN□□0804□□ | MW0804 | CTM617 | L3 | HL1813 | ML0625 | L3 |

| MWWNL2525M08 | MWWNR2525M08 | 25 | 25 | 25 | 36 | 150 | WN□□0804□□ |

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options