MVJNR TOOL HOLDER for Precision Profiling and Finishing

- Tool Type: External Turning Tool Holder (OD Turning)

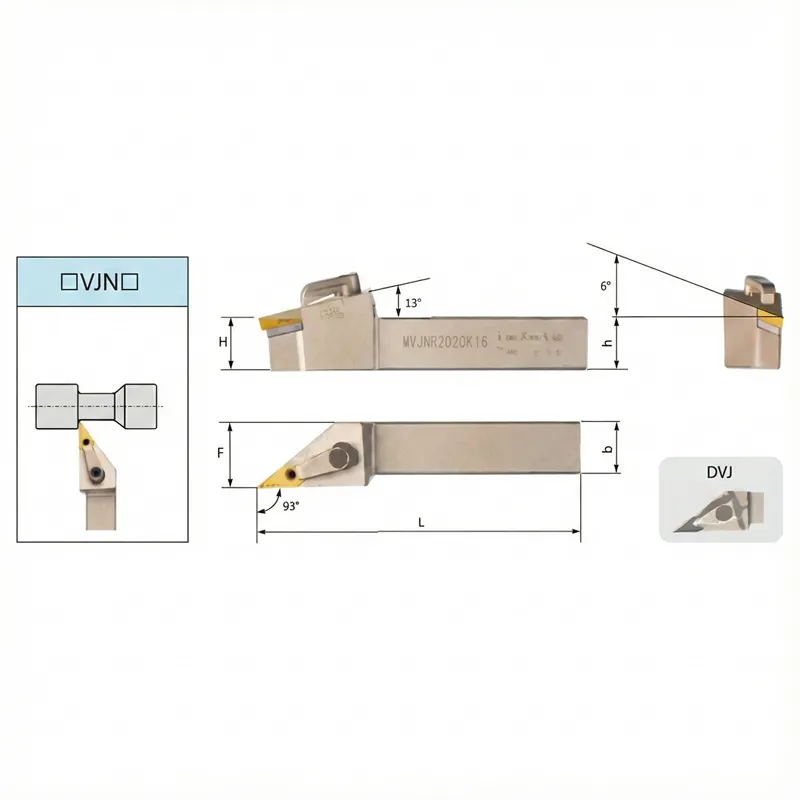

- Model Series: MVJNR/L (Right & Left Hand)

- Entering Angle: 93° Entering Angle (-3° Lead Angle)

- Clamping System: M-Type Double Clamp (Pin & Top Clamp)

- Insert Compatibility: VNMG, VNMA, VNMM (35° Diamond Inserts)

-

Key Application: Fine profiling, finishing, and copy turning of complex contours.

Contact our sales team to discover all of your pricing options.

Overview

The MVJNR/L series is the specialist choice for CNC profiling and semi-finishing operations. Unlike broad roughing tools, the MVJNR is designed with a slender geometry, utilizing a 35° diamond insert (VNMG). Combined with a 93° entering angle, this tool offers exceptional accessibility, allowing it to machine complex undercuts, deep profiles, and intricate contours that standard tools cannot reach.

Optimized for VNMG Inserts

This holder is engineered specifically for VNMG inserts. The 35° point angle of the insert minimizes tool pressure and vibration during fine cuts, ensuring a superior surface finish. It is the ideal solution for workshops looking to upgrade their finishing capabilities on standard turning centers using MVJNR 2525 shank sizes.

Rigid M-Type Design

Despite the slender profile of the V-style insert, rigidity is maintained through the M-Type Double Clamping System. The lock pin and top clamp firmly secure the insert, preventing micro-movements during high-speed finishing. This stability is standard across the range, from the compact MVJNR 2020K16 to larger heavy-duty setups.

ISO Code Naming Rules

Here is the breakdown of the MVJNR code, highlighting its unique V-shape geometry:

| Position | Code | Parameter | Description & Technical Advantage |

| 1st | M | Clamping Method |

Multi-lock (Double Clamp): Uses pin & top clamp.

• Benefit: Essential for securing the narrow 35° insert firmly. |

| 2nd | V | Insert Shape |

35° Diamond: Fits VNMG inserts.

• Benefit: The sharpest standard turning insert, perfect for deep profiling and fine finishing. |

| 3rd | J | Holder Style |

93° Entering Angle: (-3° Lead Angle).

• Benefit: Allows for turning and facing to a square shoulder while maintaining profile access. |

| 4th | N | Clearance Angle |

Negative (0°): Insert sits perpendicular.

• Benefit: Stronger than positive inserts, offering double-sided economy (4 cutting edges). |

| 5th | R/L | Hand of Tool |

Right (R) / Left (L): Direction of cut.

• Benefit: Select based on your machine’s turret configuration. |

FAQs

Q1: What is the main use of an MVJNR TOOL HOLDER?

A: The MVJNR is primarily used for profiling (copy turning) and finishing. Its 35° insert shape allows it to trace complex shapes and get into tight corners that a CNMG (80°) or TNMG (60°) tool cannot enter.

Q2: Can I use MVJNR 2525 for heavy roughing?

A: It is not recommended. The 35° nose of the VNMG insert is structurally weaker than square or trigon inserts. While the MVJNR 2525 holder itself is rigid, the insert tip can fracture under heavy roughing loads. Use it for medium cuts or finishing.

Q3: What is the difference between MVJNR and MVQNR?

A: Both use VNMG inserts. The difference is the angle. MVJNR has a 93° angle, allowing it to cut square shoulders. MVQNR has a 107.5° angle, which provides even more clearance for undercutting and back-turning, but cannot turn a square shoulder.

| MODEL | SIZE(MM) | INSERT | SHIM | CENTER PIN | WRENCH | PLATEN | DOUBLE SCREW | WRENCH | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LEFT | RIGHT | h | b | H | F | L | |||||||

| MVJNL1616K16 | MVJNR1616K16 | 16 | 16 | 16 | 20 | 125 | VN□□1604□□ | MV1603 | CTM513 | L2 | HL2413 | ML0625 | L3 |

| MVJNL2020K16 | MVJNR2020K16 | 20 | 20 | 20 | 25 | 125 | VN□□1604□□ | ||||||

| MVJNL2525M16 | MVJNR2525M16 | 25 | 25 | 25 | 32 | 150 | VN□□1604□□ | ||||||

| MVJNL3232P16 | MVJNR3232P16 | 32 | 32 | 32 | 40 | 170 | VN□□1604□□ | ||||||

| MVJNL4040R16 | MVJNR4040R16 | 40 | 40 | 40 | 50 | 200 | VN□□1604□□ | ||||||

| MODEL | SIZE(MM) | INSERT | SHIM | SHIM SCREW | PLATEN | PLATEN SCREW | WRENCH | ||||||

| LEFT | RIGHT | h | b | L | L1 | H | F | ||||||

| DVJNL1616K16 | DVJNR1616K16 | 16 | 16 | 125 | 34 | 16 | 20 | VN□□ 1604□□ | MV1603 | D5×9 | D3310 | DM6×21 | L3 |

| DVJNL2020K16 | DVJNR2020K16 | 20 | 20 | 125 | 34 | 20 | 25 | ||||||

| DVJNL2525M16 | DVJNR2525M16 | 25 | 25 | 150 | 34 | 25 | 32 | ||||||

| DVJNL3232P16 | DVJNR3232P16 | 32 | 32 | 170 | 34 | 32 | 40 |

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options