The MTFNR/L is a professional-grade external turning tool holder engineered for precision and rigidity. Utilizing the M-Type Multi-Lock system (top clamp plus locking pin), it ensures maximum stability for TNMG triangular inserts. The distinctive 91° approach angle is specifically designed for turning square shoulders and performing longitudinal turning with a $1^\circ$ side clearance, reducing friction and improving surface finish in steel, stainless steel, and high-temp alloys.

Contact our sales team to discover all of your pricing options.

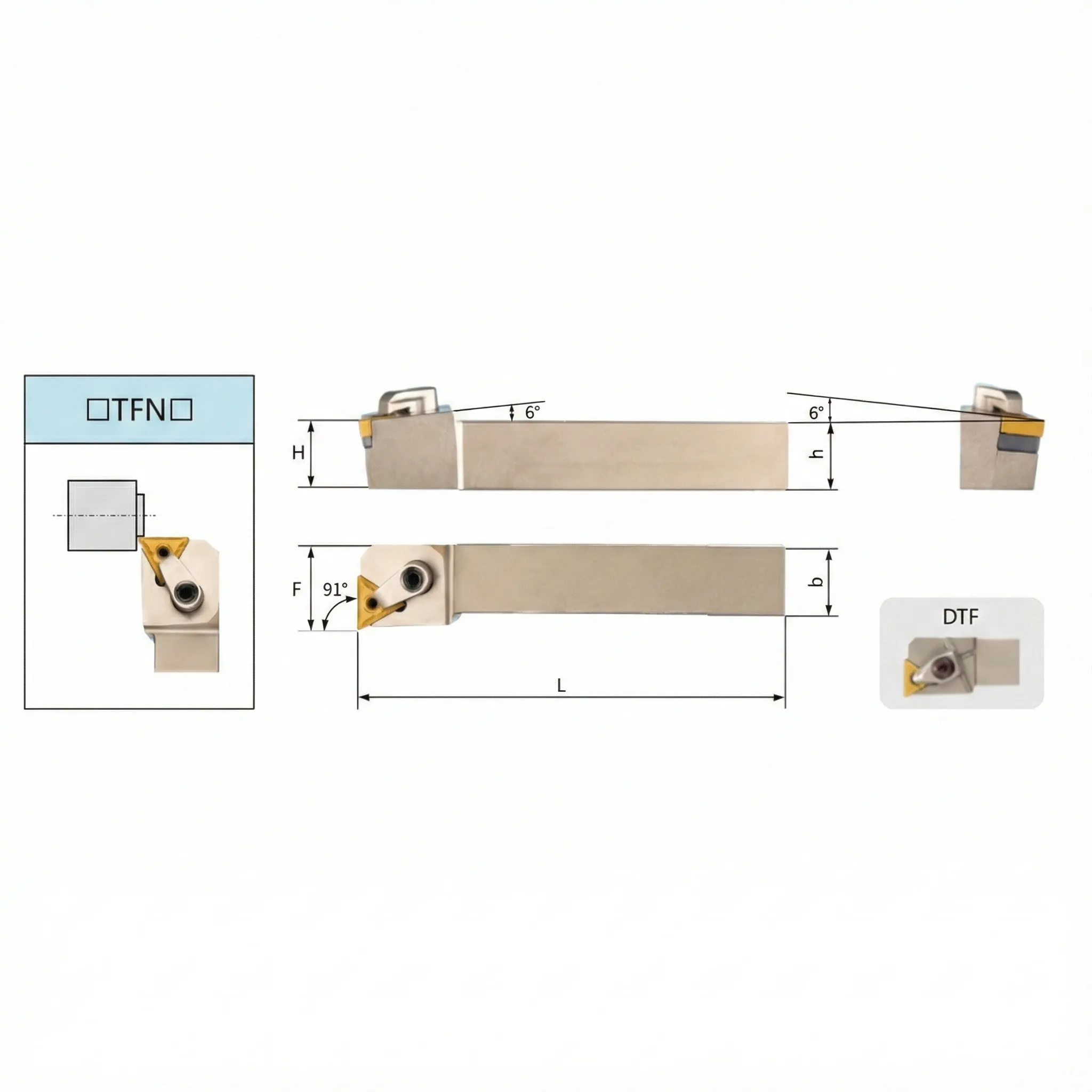

Technical Breakdown: The MTFNR/L Nomenclature

The ISO code reveals the precise engineering behind the tool’s performance:

| Position | Code | Definition | Technical Significance |

| 1st | M | Clamping System | Multi-Lock: Combines a top clamp and a dimple pin. This is the most secure method for negative inserts during heavy-duty or interrupted cuts. |

| 2nd | T | Insert Shape | Triangular (60°): Designed for TNMG inserts, providing 6 economical cutting edges per insert. |

| 3rd | F | Holder Style | 91° Approach Angle: Provides a $1^\circ$ clearance when turning 90° shoulders, preventing the trailing edge from dragging. |

| 4th | N | Clearance Angle | 0° (Negative): Utilizes the strength of negative inserts for high-volume metal removal and durability. |

| 5th | R/L | Hand of Tool | Right (R) or Left (L): Standardized for various CNC turret configurations. |

Why the 91° Approach Angle Matters

The “F” style (91°) geometry is a strategic choice for CNC machinists. By meeting the workpiece at 91°, the tool can create a perfect 90° shoulder while the secondary cutting edge maintains a slight 1° offset from the finished surface. This:

- Reduces heat generation and tool wear.

- Prevents “chatter” or vibration caused by side-cutting pressure.

-

Allows for light facing operations toward the center of the part.

Key Performance Features

- Dual-Lock Rigidity: The M-type mechanism eliminates insert “micro-movement,” extending tool life and ensuring dimensional consistency.

- Optimized Chip Flow: The negative rake geometry, combined with TNMG chipbreakers, ensures efficient chip evacuation even at high feed rates.

-

Versatile Application: Excellent for roughing to semi-finishing in a wide range of ISO materials (P, K, M, S).

Frequently Asked Questions (FAQs)

Q: Why is the approach angle 91° instead of exactly 90°?

A: A 90° approach angle (Style G) would cause the entire side of the insert to rub against the shoulder of the workpiece. The 91° angle (Style F) provides a $1^\circ$ clearance, which is essential for reducing friction, preventing vibration, and achieving a superior surface finish on the vertical face.

Q: Which inserts are compatible with the MTFNR holder?

A: It is designed for TNMG (Triangular, Negative, with Hole and Chipbreaker) inserts. The size of the insert must match the last two digits of the holder code (e.g., MTFNR 2525M16 requires TNMG 16 size inserts).

Q: Can I use this holder for facing?

A: Yes. The 91° angle allows the MTFNR/L to perform light facing operations. However, it is primarily optimized for longitudinal (O.D.) turning and shoulder work.

Q: Is the M-Type clamp better than a simple screw-on (S-Type) holder?

A: For negative inserts like the TNMG, the M-Type is significantly stronger. Screw-on types are generally reserved for smaller, positive inserts. The Multi-Lock system is the industry standard for high-productivity CNC turning.

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options