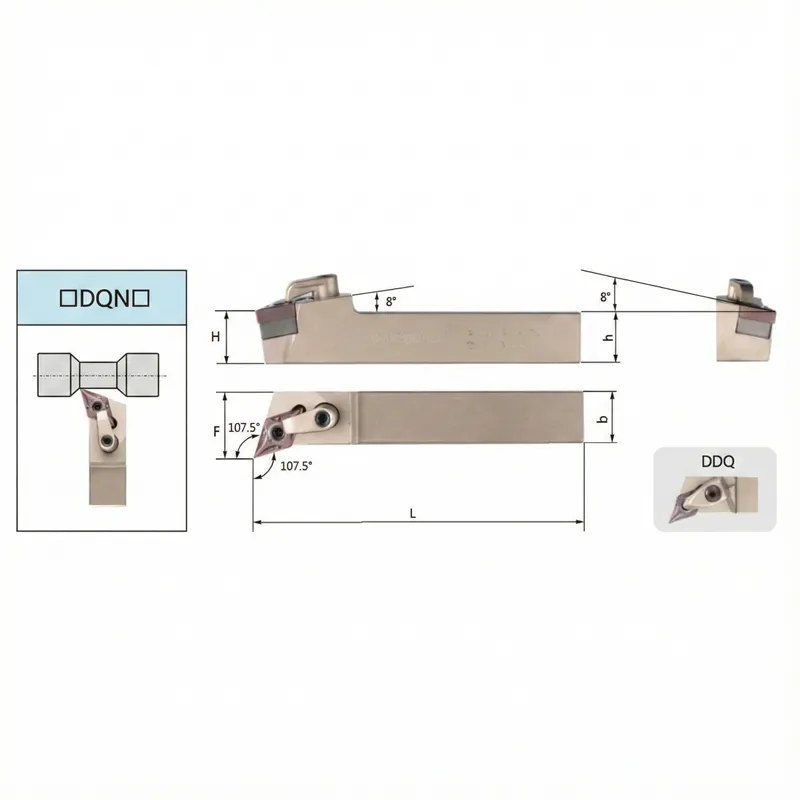

MDQNR/L Turning Tool Holder | 107.5° M-Type Holder for DNMG, DNMA & DNMM Inserts

The MDQNR/L Turning Tool Holder is a high-performance lathe tool holder engineered for specialized back-turning and intricate profiling operations. Featuring a unique 107.5-degree approach angle, this dnmg tool holder provides superior clearance when machining complex geometries. Utilizing a robust M-type double-clamping system, it is a versatile tool holder for turning that ensures maximum stability for DNMG, DNMA, and DNMM inserts.

Contact our sales team to discover all of your pricing options.

High-Stability MDQNR/L Tool Holder for Advanced Profiling

The MDQNR/L tool holder is a critical component in the lineup of CNC turning tool holder types. Its 107.5-degree approach angle allows the tool to move away from the spindle while maintaining contact with the workpiece, making it ideal for undercut machining and back-turning. As a professional lathe turning tool holder, it provides the necessary clearance to prevent the tool body from rubbing against the workpiece shoulder.

Optimized for DNMG, DNMA, and DNMM Inserts

This series is precision-crafted to accommodate 55-degree diamond inserts, allowing you to choose the best cutting edge for your material:

-

DNMG Inserts: The primary choice for general steel and stainless steel turning, often used in dnmg holder setups for balanced performance.

-

DNMA Inserts: Designed for cast iron machining where flat-top insert geometry is required for stability.

-

DNMM Inserts: A heavy-duty roughing option for interrupted cuts, offering reinforced edge strength within the indexable turning tool holders category.

Rigid M-Type Multi-Lock Clamping System

To maintain precision during directional changes, the MDQNR/L features an M-type clamping mechanism. This “Multi-lock” system secures the lathe insert holder via both a top clamp and a center pin. This dual-locking action provides significantly higher rigidity than standard screw-down systems, ensuring that your dnmg tool holder remains perfectly stationary under high feed rates, resulting in superior surface accuracy.

Specifications Table

| Feature | Details |

| Model Number | MDQNR (Right Hand) / MDQNL (Left Hand) |

| Tool Category | Indexable Turning Tool Holders |

| Clamping System | M-Type (Double Clamp / Multi-lock) |

| Approach Angle | 107.5° (Ideal for Back-Turning) |

| Compatible Inserts | DNMG, DNMA, DNMM (Size 1504 / 1506) |

| Body Material | Hardened High-Alloy Steel |

| Primary Use | Profiling, Longitudinal Turning, Undercutting |

Q: What is the main advantage of the 107.5° angle on the MDQNR/L?

A: The 107.5° approach angle on the MDQNR/L allows for “pulling” cuts or back-turning. This is essential when you need to turn a profile towards the tailstock or clear a shoulder that a 93° dnmg tool holder cannot reach.

Q: Can I use this for heavy roughing?

A: Yes. Thanks to the M-type double-clamping system, the MDQNR/L is much more stable than a typical lathe insert holder. It can handle the cutting pressures of DNMM inserts during roughing, though its primary strength is precision profiling.

Q: How does this holder improve tool life?

A: By securing the DNMG insert at two contact points, the M-type clamp eliminates micro-vibrations. Reducing vibration is the most effective

| MODEL | SIZE(MM) | INSERT | SHIM | CENTER PIN | WRENCH | PLATEN | DOUBL SCREW | WRENCH | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LEFT | RIGHT | h | b | H | F | L | |||||||

| MDQNL1616H11 | MDQNR1616H11 | 16 | 16 | 16 | 20 | 100 | DN□□1104□□ | MD1103 | CTM513 | L2 | HL1813 | ML0625 | L3 |

| MDQNL2020K11 | MDQNR2020K11 | 20 | 20 | 20 | 25 | 125 | DN□□1104□□ | ||||||

| MDQNL2525M11 | MDQNR2525M11 | 25 | 25 | 25 | 32 | 150 | DN□□1104□□ | ||||||

| MDQNL2020K15 | MDQNR2020K15 | 20 | 20 | 20 | 25 | 125 | DN□□1504□□ DN□□1506□□ | MD1506 MD1504 | CTM619 | L3 | HL2113 | ML0625 | L3 |

| MDQNL2525M15 | MDQNR2525M15 | 25 | 25 | 25 | 32 | 150 | DN□□1504□□ DN□□1506□□ | ||||||

| MDQNL3232P15 | MDQNR3232P15 | 32 | 32 | 32 | 40 | 170 | DN□□1504□□ DN□□1506□□ |

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options