MCKNR/L Turning Tool Holder | 75° M-Type Double Clamp Lathe Tool Holder for CNMG

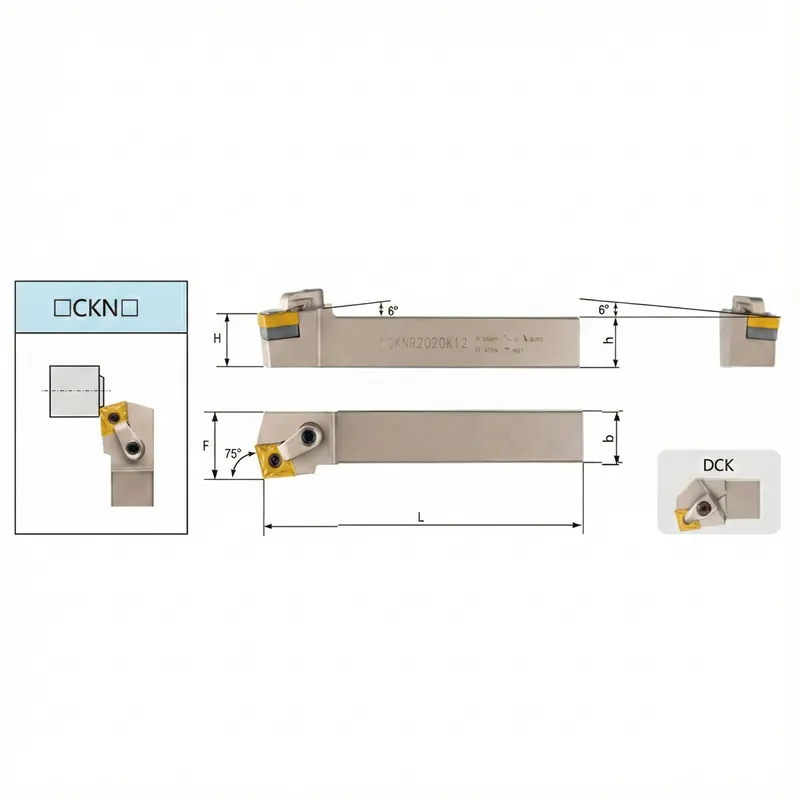

Optimize your heavy-duty machining with the MCKNR Turning Tool Holder. This professional indexable turning tool holder features a 75-degree approach angle, ideal for high-removal rate operations. Built with a robust M-type double-clamping system, the MCKNR ensures maximum stability for CNMG inserts, making it a top choice among CNC turning tool holder types.

Contact our sales team to discover all of your pricing options.

High-Stability MCKNR Lathe Tool Holder for Heavy Roughing

The MCKNR tool holder is specifically engineered for external turning where high material removal rates and tool rigidity are the top priorities. As a premier lathe turning tool holder (110 searches/mo), the MCKNR series is the “heavy-duty sibling” in the CNMG holder family.

75° Approach Angle for Superior Strength

The standout feature of the MCKNR tool holder is its 75-degree approach angle. Unlike 91° or 95° holders, this geometry:

-

Distributes Cutting Forces: Spreads the load over a larger portion of the carbide edge.

-

Protects the Insert: Ideal for heavy-duty roughing and interrupted cuts.

-

Enhances Heat Dissipation: Allows for faster feed rates without compromising the CNMG tool holder setup.

M-Type Double Clamping (Multi-Lock)

Safety and precision are guaranteed by the M-type clamping system. This system uses a top clamp and a center pin to lock the lathe insert holder securely. It prevents any rotation or lifting of the insert, which is crucial when performing the high-torque operations that the MCKNR is designed for.

Specifications

| Feature | Specifications |

| Product Model | MCKNR (e.g., MCKNR 2525 M12) |

| Primary Category | Turning Tool Holder |

| Clamping Method | M-Type Double Clamp (Multi-lock) |

| Approach Angle | 75° (Ideal for Roughing) |

| Compatible Inserts | CNMG 1204 / CNMG 432 |

| Hand Direction | Right Hand (Standard) / Left Hand |

| Shank Sizes Available | 20x20mm, 25x25mm, 32x32mm |

Q: When should I use MCKNR instead of PCLNR?

-

A: Use the MCKNR when you need extra tool strength for heavy roughing or when dealing with scaly surfaces. The 75° angle is much stronger than the 95° angle of a PCLNR, although it cannot be used for 90-degree shoulders.

| MODEL | SIZE(MM) | INSERT | SHIM | CENTER PIN | WRENCH | PLATEN | DGUBLE SCREW | WRENCH | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LEFT | RIGHT | h | b | H | F | L | |||||||

| MCKNL1616H12 | MCKNR1615H12 | 16 | 16 | 15 | 20 | 100 | CN□□1204□□ | MC1204 | CTM617 | L3 | HL1813 | ML0625 | 3 |

| MCKNL2020K12 | MCKNR2020K12 | 20 | 20 | 20 | 25 | 125 | CN□□1204□□ | ||||||

| MCKNL2525M12 | MCKNR2525M12 | 25 | 25 | 25 | 32 | 150 | CN□□1204□□ | ||||||

| MCKNL3232P12 | MCKNR3232P12 | 32 | 32 | 32 | 40 | 170 | CN□□1204□□ | ||||||

| MCKNL4040R12 | MCKNR4040R12 | 40 | 40 | 40 | 50 | 200 | CN□□1204□□ | ||||||

| MCKNL2525M16 | MCKNR2525M16 | 25 | 25 | 25 | 32 | 150 | CN□□1606□□ | MC1604 | CTM0822 | L3 | HL2217 | ML0830 | L4 |

| MCKNL3232P16 | MCKNR3232P16 | 32 | 32 | 32 | 40 | 170 | CN□□1606□□ | ||||||

| MCKNL4040R16 | MCKNR4040R15 | 40 | 40 | 40 | 50 | 200 | CN□□1606□□ | ||||||

| MCKNL3232P19 | MCKNR3232P19 | 32 | 32 | 32 | 40 | 170 | CN□□1906□□ | MC1904 | CTM1022 | L4 | HL2217 | ML0830 | L4 |

| MCKNL4040R19 | MCKNR4040R19 | 40 | 40 | 40 | 50 | 200 | CN□□1906□□ |

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options