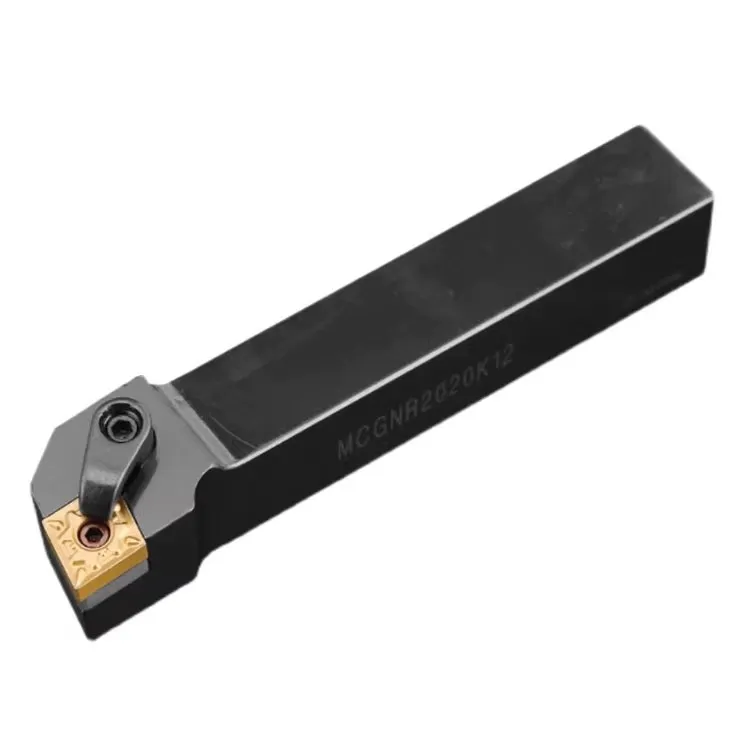

Maximize your machining stability with the MCGNR Turning Tool Holder. Designed as a high-performance indexable lathe tool holder, the MCGNR series utilizes a robust M-type double-clamping system to ensure the highest rigidity during heavy-duty external turning. Perfectly compatible with CNMG inserts, this tool holder for turning is the industry standard for precision and durability.

Contact our sales team to discover all of your pricing options.

High-Performance MCGNR Tool Holder for CNC Turning

The MCGNR tool holder is an essential part of any professional CNC setup, categorized under the most reliable CNC turning tool holder types. It is specifically engineered for external turning operations where surface finish and dimensional accuracy are critical.

M-Type Double Clamping System for Maximum Rigidity

Unlike standard S-type holders, the MCGNR features a Multi-lock (M-type) system. This double-clamp design secures the CNMG insert from both the top and the center hole. This results in:

-

Reduced Vibration: Perfect for interrupted cuts and high-speed machining.

-

Longer Insert Life: Stability prevents micro-chipping of the carbide edges.

-

Extreme Precision: Maintains tight tolerances even in heavy-duty lathe turning tool holder applications

Optimized for CNMG Inserts

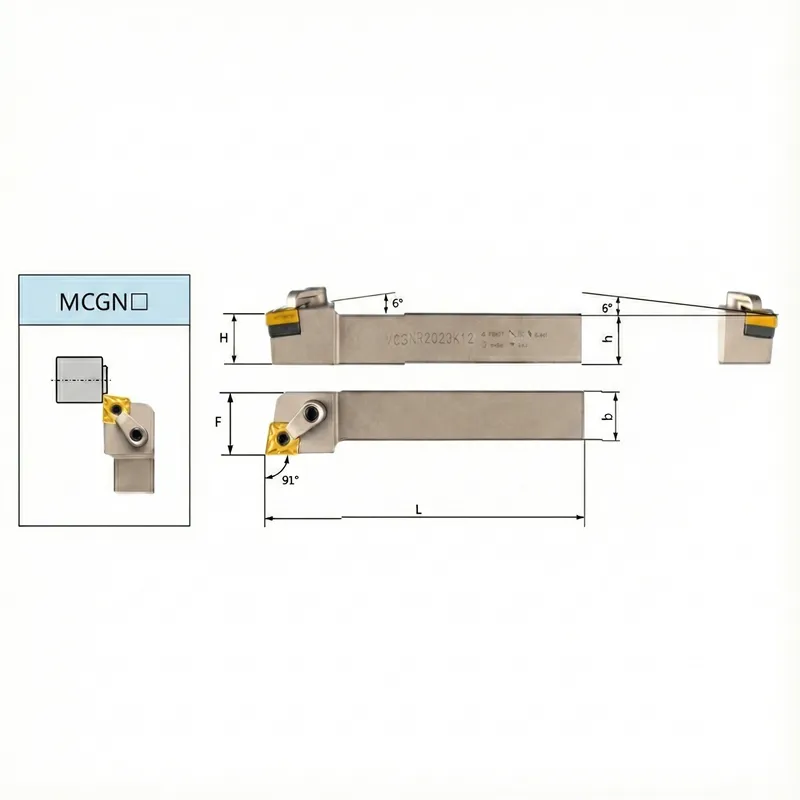

As a dedicated CNMG tool holder, the MCGNR is optimized for 80-degree diamond inserts. This geometry allows for versatile 91-degree approach angles, making it ideal for facing and longitudinal turning. Whether you are using it as a right-hand lathe tool holder or for general OD turning, it provides unmatched chip clearance and heat dissipation.

Specifications

| Feature | Specifications |

| Product Model | MCGNR (e.g., MCGNR 2020K12 / 2525M12) |

| Tool Type | External Turning Tool Holder |

| Clamping System | M-Type (Double Clamp / Multi-lock) |

| Compatible Insert | CNMG 1204 / CNMG 432 |

| Approach Angle | 91° |

| Material | High-Quality Alloy Steel (Hardened) |

| Applications | Roughing to Finishing, Interrupted Cuts |

-

Q: Why choose an MCGNR tool holder over a PCLNR?

-

A: While both are CNMG tool holders, the MCGNR uses a double-clamping (M-type) system which provides more downward pressure than the P-type lever system, making it better for heavy-duty or interrupted turning tool holder applications where insert movement must be zero.

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options