Carbide MGMN Grooving Insert Series

Unlock maximum efficiency in your metalworking operations with our top-tier MGMN series. As a critical component in modern machining, a high-quality CNC grooving insert determines the stability and finish of your parting and grooving tasks. Our MGMN insert lineup is engineered with a unique double-ended design, offering a cost-effective solution without compromising on edge strength or precision.

Contact our sales team to discover all of your pricing options.

Comprehensive Range: From MGMN 150 to MGMN 500

We stock a complete spectrum of sizes to meet every dimensional requirement. Whether you are performing delicate parting-off or heavy-duty groove turning, our specific distinct widths ensure you have the right tool for the job:

- Small Widths (1.5mm – 2.0mm): Ideal for material saving and reduced cutting forces. Our MGMN 150 is the perfect choice for precision work, specifically optimized for MGMN 150 grooving applications where minimizing waste is critical.

- Medium Widths (2.5mm – 3.0mm): The industry standard for versatility. The MGMN 300 insert is our best-seller, capable of handling a vast array of materials. For general steel machining, the MGMN 300 M geometry offers exceptional chip control and surface finish.

-

Large Widths (4.0mm – 6.0mm): Designed for maximum stability in deep grooves. Choose the MGMN 400 or the heavy-duty MGMN 500 for interrupted cuts and high-feed turning operations.

Specialized Geometries for Every Material

Choosing the right grooving insert geometry is as important as selecting the right grade. Our grooving inserts are available in four optimized chipbreakers:

- -G (Cut-Off Specialist): Designed for efficiency. Perfect for users needing a dedicated carbide grooving insert for parting-off bars and pipes.

- -M (General Purpose): The all-rounder. Whether you are using an MGMN 300 insert or other sizes, the -M geometry ensures smooth chip flow in steel and stainless steel.

- -T (Turning & Grooving): Reduces cutting resistance by 20%. This design allows for side turning (transverse motion), making it a truly multi-functional MGMN insert.

-

-DR (Chip Breaking): The solution for difficult chip evacuation. Ideal for internal grooving or small spaces where standard grooving inserts might clog.

Premium Grades for Extended Life

To ensure your CNC grooving insert performs under pressure, we offer advanced PVD and CVD coatings:

- D9050 (Universal): A tough PVD grade for Steel and Stainless Steel.

- D3020 (Steel): A thick CVD grade for maximum wear resistance in continuous steel cutting.

-

D7040 (Precision): High-precision PVD grade for small parts and demanding tolerances.

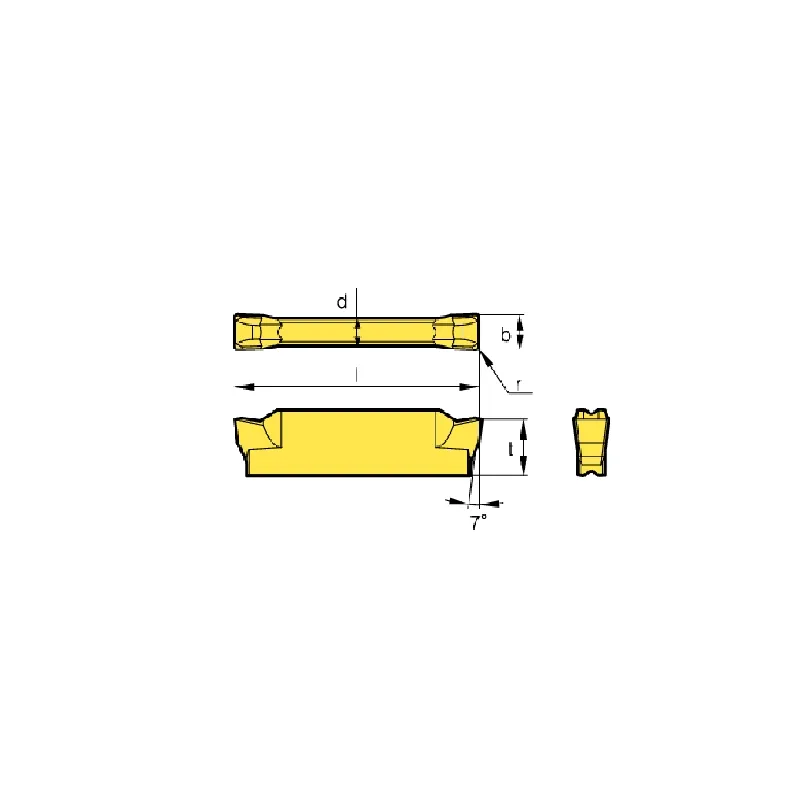

Model Data Sheet

| Picture | Type | L (mm) | W (mm) | S (mm) | RE (mm) | Application |

|---|---|---|---|---|---|---|

| MGMN150-G | 16 | 1.5 | 4 | 0.75 | Parting and Grooving |

| MGMN200-G | 16 | 2 | 4 | 0.2 | ||

| MGMN250-G | 18.5 | 2.5 | 4.5 | 0.2 | ||

| MGMN300-G | 21 | 3 | 5.6 | 0.3 | ||

| MGMN200-M | 16 | 2 | 4 | 0.2 | Parting, Grooving and Turning |

| MGMN250-M | 18.5 | 2.5 | 4.5 | 0.2 | ||

| MGMN300-M | 21 | 3 | 5.6 | 0.4 | ||

| MGMN400-M | 21 | 4 | 5.8 | 0.4 | ||

| MGMN500-M | 26 | 5 | 5.8 | 0.8 | ||

| MGMN600-M | 26 | 6 | 5.9 | 0.8 | ||

| MGMN200-T | 16 | 2 | 3.55 | 0.2 | Grooving,Turning and Cross feed |

| MGMN250-T | 18.5 | 2.5 | 4.5 | 0.2 | ||

| MGMN300-T | 21 | 3 | 4.86 | 0.4 | ||

| MGMN400-T | 21 | 4 | 4.86 | 0.4 | ||

| MGMN500-T | 26 | 5 | 5.8 | 0.8 | ||

| MGMN200 | 16 | 2 | 3.55 | 0.2 | Large rake angle design with good chip flow. Small cutting resistance and not prone to sticking. The chip control effect is excellent. |

| MGMN300 | 21 | 3 | 4.86 | 0.4 | ||

| MGMN400 | 21 | 4 | 4.86 | 0.4 | ||

| MGMN500 | 26 | 5 | 5.8 | 0.8 | ||

| MGMN200-DR | 16 | 2 | 4 | 0.2 | Chip-breaking High Gloss, Cross feed |

| MGMN250-DR | 18.5 | 2.5 | 4.5 | 0.2 | ||

| MGMN300-DR | 21 | 3 | 5.6 | 0.4 | ||

| MGMN400-DR | 21 | 4 | 5.8 | 0.4 | ||

| MGMN500-DR | 26 | 5 | 5.8 | 0.8 |

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options