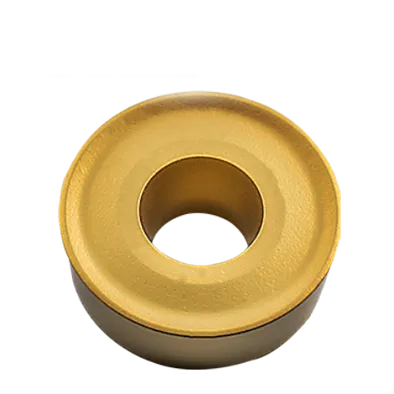

RCMX insert

RCMX insert angle: 7° Positive Rake Screw-On Insert with single-sided Chipbreaker;

Recommended for wide range of materials

Breaker Application: Semi-roughing & Roughing machining

Matching TurningTool Holder: SRGCRL,SRDCN

RCMX Insert can deal with multiple operations by combining different chip breakers and grades.

Material : Tungsten Carbide

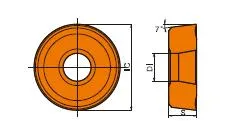

RCMX insert specification

RCMX round insert suitable for roughing and semi-roughing, the special chipformer design ensures the rigidity of the insert in the face of the complexity of roughing, but also ensures that it is capable of continuous machining.

RCMX insert Meaning

Understanding the RCMX Insert Code

- R: Shape: Round. RCMX inserts are round but have cutting edges spaced around the circumference for indexing.

- C: Clearance Angle: Positive, often small (around 7 degrees) for general-purpose use, though variations for specific materials can exist.

- M: Tolerance: Medium tolerance (‘M’) is most typical, but precision tolerances might be available.

- X: Chipbreaker style & Hole Configuration. This letter denotes the specific chipbreaker and whether the insert has a hole. Chipbreaker variations are manufacturer-specific, so always check their resources.

- Numerical Digits:

- First Two Digits: Inscribed Circle (IC) diameter in millimeters. To obtain the approximate inch equivalent, divide this number by 25.4.

- Next Two Digits: May refer to thickness or other dimensions depending on the manufacturer. It’s crucial to consult the specific manufacturer’s catalog.

RCMX Insert Dimensions (ISO)

| RCMX Designation | LE | IC | S | D1 |

|---|---|---|---|---|

| RCMX 0803MO | 8 | 8 | 3.18 | 3.4 |

| RCMX 1003MO | 10 | 10 | 3.18 | 3.6 |

| RCMX 1204MO | 12 | 12 | 4.76 | 4.4 |

| RCMX 1606MO | 16 | 16 | 6.35 | 5.5 |

| RCMX 2006MO | 20 | 20 | 6.35 | 6.5 |

| RCMX 2507MO | 25 | 25 | 7.94 | 7.2 |

| RCMX 3509MO | 32 | 32 | 9.52 | 9.5 |

Example: RCMX 1204MO

- Round shape: with multiple cutting edges.

- 0-degree clearance angle (or potentially a slight positive angle)

- Medium tolerance.

- Manufacturer-specific chipbreaker and hole configuration.

- 12mm inscribed circle diameter (approx. 0.47″ in inches)

- “04” and “MO” will have manufacturer-specific meanings for thickness, edge style, etc.

The Science Behind Carbide Inserts: How They're Made and Why They're So Strong

Carbide inserts are some of the most versatile and durable cutting tools available. But how are they made? And what makes them so strong? In this video, we’ll explore the science behind carbide inserts, from the properties of tungsten carbide to the manufacturing process.

Our Production Capability