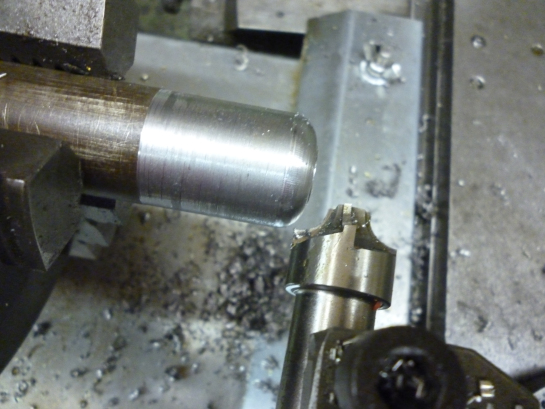

Carbide lathe form tool

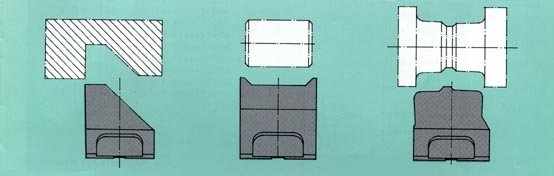

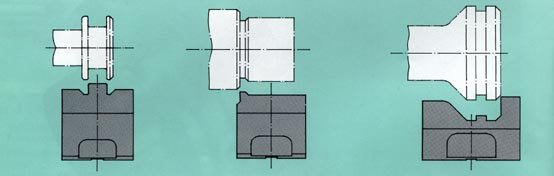

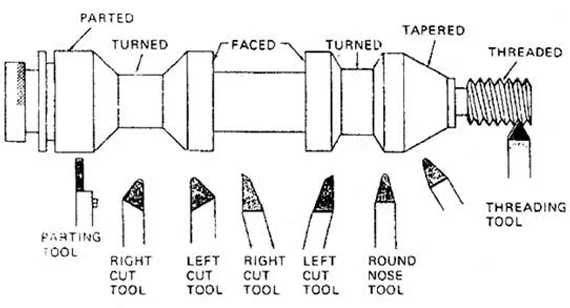

A lathe form tool (also known as a forming tool) is a special turning tool used to machine complex contours or specific shapes (such as arcs, grooves, or multi-step features) in a single pass on a lathe. It is particularly suitable for high-volume production.

Common carbide lathe form tool machining methods

- Grinding: Most common; uses diamond wheels for precision profiling of flat or circular form tools.

- Electrical Discharge Machining (EDM/Wire EDM): Ideal for complex profiles; non-contact process minimizes chipping risk.

- Brazing: Carbide blanks are brazed onto a steel shank and then profiled.

- Powder Metallurgy + Sintering: For mass-produced blanks, followed by finishing.

- Modern Methods: Laser profiling or CNC grinding for high precision.

| Method | Suitability | Advantages | Disadvantages |

|---|---|---|---|

| Grinding | General, precise profiles | High accuracy, good surface | Requires diamond wheels, slow |

| EDM | Complex shapes | No force, extremely precise | Expensive equipment, slow |

| Brazing | Custom tools | Lower cost, easy repair | Heat-affected zone, slightly lower strength |

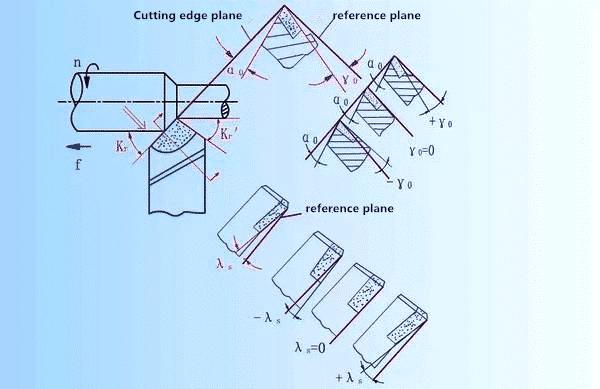

Tool Geometry Design

Key angles for carbide form tools (to balance strength and performance):

- Rake angle: Typically 0° to +10° (positive for better cutting).

- Clearance angle: 7°–15° to prevent rubbing.

- Side relief and edge radius for chip flow and strength.

The edge must mirror the workpiece profile exactly.

FAQ

A lathe form tool has a cutting edge ground to mirror the desired workpiece profile. It uses radial plunge cutting to form complex contours (e.g., grooves, radii, or multi-step shapes) in a single pass. This makes it ideal for high-volume production of identical parts.

- Advantages: Faster for complex profiles (one pass vs. multiple), better consistency, superior surface finish (no cusp marks), and longer tool life (wear distributed across the edge). Disadvantages: High cutting forces require a rigid machine; custom tools are expensive; not flexible for varied work; prone to chatter on lighter lathes.

Generally no—small lathes often lack the rigidity needed, leading to severe chatter, vibration, or poor results. They work best on heavy, industrial machines or for high-production runs.

- For flat form tools, grind only the top face (rake) to maintain the profile. Circular form tools are easier as regrinding the face doesn't alter the radius. Use diamond wheels for carbide; avoid changing side clearances.

Common causes: Insufficient machine rigidity, tool overhang, high forces from wide cuts, improper height (tool not on center), or lack of coolant. Solutions: Reduce depth/feed, increase rigidity, use spindle speed variation, or rough with another tool first.

Mirror the workpiece profile exactly. Provide 7–15° clearance angles to avoid rubbing; use minimal rake (0–10°); add a small hone radius for strength. For radii, circular tools are preferred.

Yes, they're excellent for cycle time reduction on repetitive profiles. Program straight radial plunges; roughing passes may be needed for deep/wide forms to avoid overload.

Interested To Our Tools?

ONMY Toolings is growing rapidly these years, and we are always welcome partners to work together to achieve manual benifits and grow together!