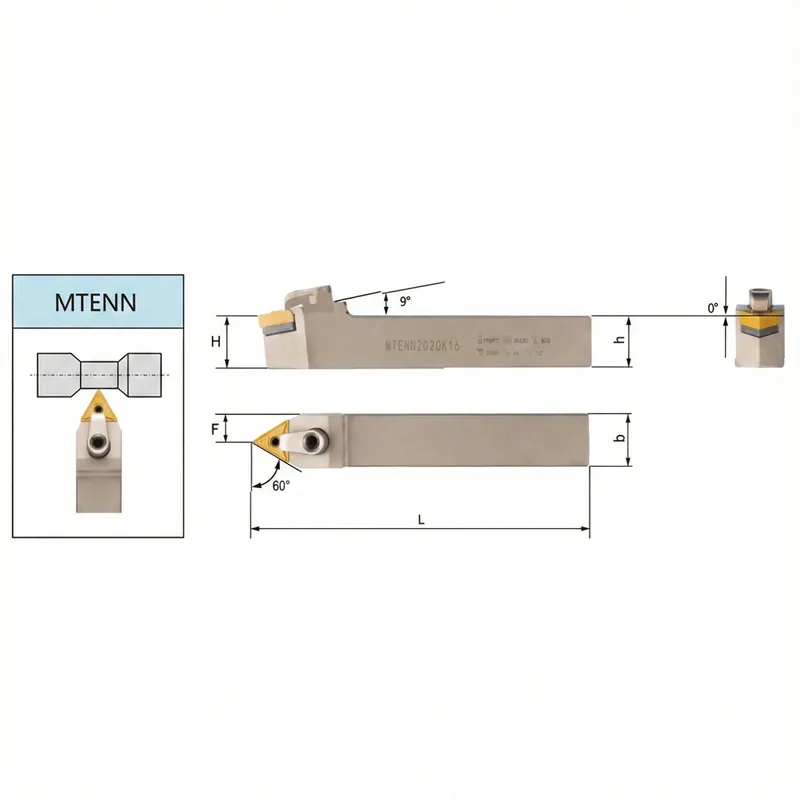

- Werkzeugtyp: Neutraler Werkzeughalter für Außendrehen (Außendrehen)

- Modellreihe: MTENN (Neutrale Handgestaltung)

- Eintrittswinkel: 60° Eintrittswinkel (30° Vorlaufwinkel)

- Mechanismus zum Klemmen: M-Type Double Clamp (Pin-lock & Top Clamp) für maximale Steifigkeit.

- Kompatibilität einfügen: Passt zu TNMG, TNMA, TNMM (Negative Triangle Inserts).

-

Am besten geeignet für: Profilieren, Kopierdrehen und multidirektionale Bearbeitung auf CNC-Drehmaschinen.

Wenden Sie sich an unser Verkaufsteam, um alle Ihre Preisoptionen zu erfahren.

Übersicht Die MTENN-Serie ist ein spezieller neutraler Außendrehhalter, der für Vielseitigkeit und Präzision entwickelt wurde. Im Gegensatz zu rechts- oder linksseitigen Standardwerkzeugen verfügt der MTENN über ein symmetrisches Design mit einem Eintrittswinkel von 60°. Diese Geometrie macht ihn zu einer ausgezeichneten Wahl für das CNC-Profilieren, das Kopierdrehen und Bearbeitungen, die bidirektionale Schnittfähigkeiten oder spezifische Freiwinkel erfordern.

Wirtschaftlichkeit und Leistung (TNMG-Einsätze) Optimiert für TNMG-Wendeplattenhalteranwendungen, verwendet dieses Werkzeug dreieckige negative Einsätze.

-

6 Schnittkanten: Die dreieckige Form bietet 6 nutzbare Schneidkanten pro Wendeschneidplatte (3 pro Seite) und damit eine äußerst wirtschaftliche Lösung für die Kosten pro Schneidkante.

-

Sorte einfügen: Vollständig kompatibel mit den Wendeschneidplatten TNMG (Spanbrecher), TNMA (Flat Top für Gusseisen) und TNMM (Schruppen).

-

Zugang: Der 60-Grad-Winkel ermöglicht im Vergleich zu quadratischen Einsatzhaltern einen besseren Zugang zu engen Ecken und Aussparungen.

Starre M-Typ Doppelklemmung Bei Profilierarbeiten treten häufig unterschiedliche Schnittkräfte auf. Der MTENN ist mit dem branchenüblichen M-Typ-Doppelklemmsystem ausgestattet. Die Kombination aus einem Verriegelungsstift und einer hochbelastbaren oberen Klemme sorgt dafür, dass die Wendeplatte sicher in der Tasche sitzt und auch bei wechselnden Schnittrichtungen nicht vibriert.

Die 5-Buchstaben-Präfixe: Geometrie und Einspannung

Die ersten fünf Buchstaben definieren die “Persönlichkeit” des Werkzeughalters.

| Position | Brief | Kategorie | Beschreibung |

| 1. | M | Spannsystem | Mehrfachverriegelung: Verwendet sowohl eine obere Klemme als auch einen Sicherungsstift. Dies ist das stabilste System, ideal für schwere Schrupparbeiten. |

| 2. | T | Form einfügen | Dreieckig: Verwendet dreieckige 60°-Wendeplatten (z. B. TNMG). Diese Form bietet 6 Schneidkanten (3 pro Seite) und ist damit sehr wirtschaftlich. |

| 3. | E | Halterungstyp | 60° Anflugwinkel: Der Winkel, in dem die Schneide auf das Werkstück trifft. Die Form ‘E’ wird normalerweise zum Drehen und Plandrehen verwendet. |

| 4. | N | Freiraum-Winkel | 0° (negativ): Zeigt an, dass der Halter für negative Einsätze ausgelegt ist. Negative Einsätze sind stärker und ermöglichen eine beidseitige Verwendung. |

| 5. | N | Hand des Werkzeugs | Neutral: Das Werkzeug ist zentriert und kann in beide Richtungen schneiden oder wird für symmetrische Anwendungen verwendet. (R = Rechts, L = Links). |

Das numerische Suffix: Physikalische Dimensionen

Nach den Buchstaben (z. B., 2020K16) finden Sie Zahlen, die den physischen Schaft und die Größe der Wendeschneidplatte beschreiben, für die er geeignet ist.

Querschnitt des Schaftes (2020)

-

20: Schafthöhe ($20\text{ mm}$)

-

20: Schaftbreite ($20\text{ mm}$)

Werkzeuglänge (K)

Der Buchstabe an 8. Stelle steht für die Gesamtlänge des Halters.

-

K: 125 mm

-

P: 170 mm

-

M: 150 mm

Länge der Schnittkante (16)

Die letzten beiden Ziffern geben die Größe der Beilage an.

-

16: Konzipiert für einen Einsatz mit einer 16mm Schneidkante (z.B., TNMG 160408).

Warum sollten Sie sich für das MTENN-System entscheiden?

Der MTENN-Halter ist aus mehreren Gründen ein “Arbeitstier” in CNC-Werkstätten:

-

Extreme Steifheit: Die “M”-Klemmung (Multi-Lock) verhindert ein Verrutschen des Einsatzes bei starker seitlicher Belastung.

-

Vielseitigkeit: Da es sich um ein neutrales (N) Werkzeug handelt, wird es häufig für die Profilerstellung oder in Aufbauten verwendet, bei denen ein einziges Werkzeug mehrere Ausrichtungen durchführen muss.

-

Wirtschaft: Durch die Verwendung dreieckiger (T) negativer Einsätze erhalten Sie die maximale Anzahl an nutzbaren Kanten pro ausgegebenem Dollar.

Profi-Tipp: Achten Sie immer darauf, dass der 4. Buchstabe Ihres Halters (Freiwinkel) mit dem 2. Buchstaben Ihres Einsatzes übereinstimmt. Für einen MTENN-Halter müssen Sie einen Einsatz mit einem N an der zweiten Position verwenden (wie TNMG).

Q1: Was ist der Hauptvorteil eines “neutralen” (MTENN) Halters?

A: Ein neutraler Drehmeißel ist symmetrisch. Er eignet sich für spezielle Aufbauten, bei denen das Werkzeug senkrecht zur Achse an das Werkstück herangeführt werden muss, oder für spezielle Profilierungsarbeiten, bei denen auf beiden Seiten der Werkzeugnase Freiraum benötigt wird.

F2: Kann ich TNMA-Einsätze in diesem Halter verwenden?

A: Ja, der MTENN ist mit TNMG-, TNMA- und TNMM-Einsätzen kompatibel. Durch die Verwendung von TNMA-Wendeplatten (flache Spitze) eignet sich dieser Halter hervorragend für die Bearbeitung von Gusseisen, während TNMG für Stahl und Edelstahl bevorzugt wird.

F3: Ist der dreieckige Einsatz (TNMG) besser als der quadratische (SNMG)?

A: Dies hängt von der Anwendung ab. Die TNMG-Wendeplatte hat einen 60°-Spitzenwinkel, der schwächer ist als die 90°-Vierkant-Wendeplatte (SNMG), aber eine bessere Zugänglichkeit für Profilierungen und Hinterschneidungen bietet. Außerdem bietet sie 6 Schneidkanten und ist damit sehr kostengünstig.

F4: Was ist der Eintrittswinkel von MTENN?

A: Der MTENN verfügt über einen 60°-Eingriffswinkel (in manchen Regionen auch als 30°-Anstiegswinkel bezeichnet). Diese Geometrie gleicht die radialen und axialen Schnittkräfte anders aus als ein Standardwerkzeug mit 95°, so dass es sich für schwere Schnitte eignet, wenn die Teilekonfiguration dies zulässt.

Benötigen Sie eine Beratung? Kontaktieren Sie uns!

Wenden Sie sich an unser Vertriebsteam, um alle Ihre Preisoptionen zu erfahren