Single flute end mill

This is a set of single flute end mill cutting tool used in industrial milling applications. It is distinguished from the drill bit in its application, geometry, and manufacture. Single flute end mills are used for superior chip evacuation in high-speed milling. These end mills are made of tungsten carbide which will tolerate a lot more heat while still keep a good hardness., they possess only one cutting edge, which offers distinct advantages in Aluminum, MDF, solid wood, plastic, and acrylic.

Application

- Engraving Machine, CNC Router Machine -3 Axis, 4 Axis and 5 Axis (Engraving machine and CNC machine -3 axis, 4 axis, 5 axis)

- Application: Suit for cutting Wood, Plastic, and Acrylic plate

Features

- This end mill set is made from high-quality tungsten carbide for good hardness and sharp cutting edge.

- 3.175mm — 1/2 inch standard shank diameter would fit many milling machines or CNC cutting machines.

- Single flute designed end mill with a sharp cutting edge would offer a smooth cutting surface and chip clearing.

- Usually, end mills are used for cutting acrylic, PVC, MDF, density board, wood, and many other soft materials.

- Mix &Match model no. in one batch is acceptable.

- For distributors, we can label your brands on cutters and plastic boxes.

- Mix &Match coating of tools in one batch is acceptable.

- AlTiN, TiAlN, TiSiN, TiN, DLC (Diamond coating), Nano, and Diamond for you to choose to win over your competitors.

- HS Code reference for you to control everything:8207709000.

Single flute End Mills gallery

Step into the world of unparalleled cutting precision with ONMY TOOLINGS’s extraordinary lineup of single flute end mill. From micro-machining marvels to heavy-duty workhorses, our diverse range is designed to conquer every milling challenge you face.

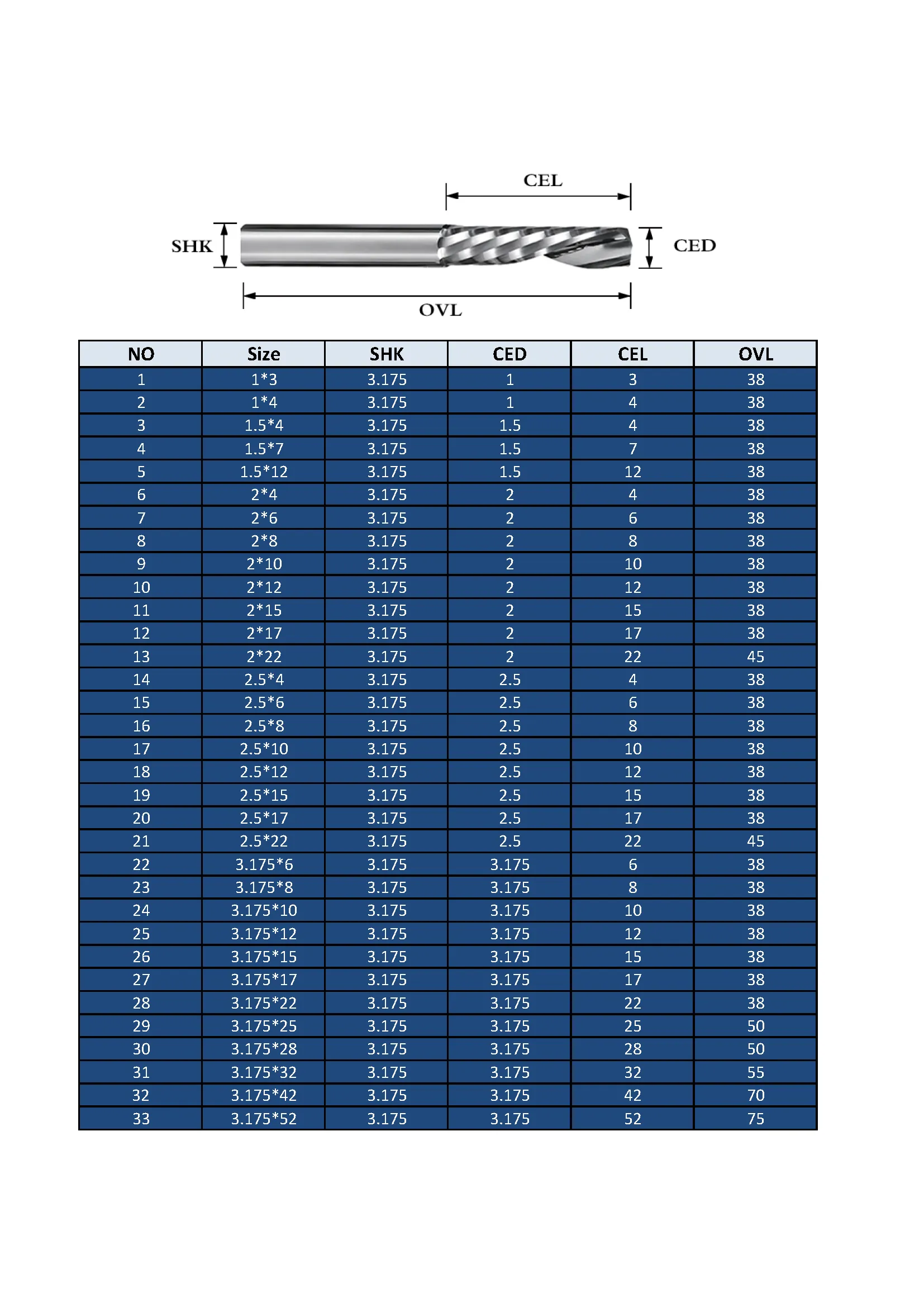

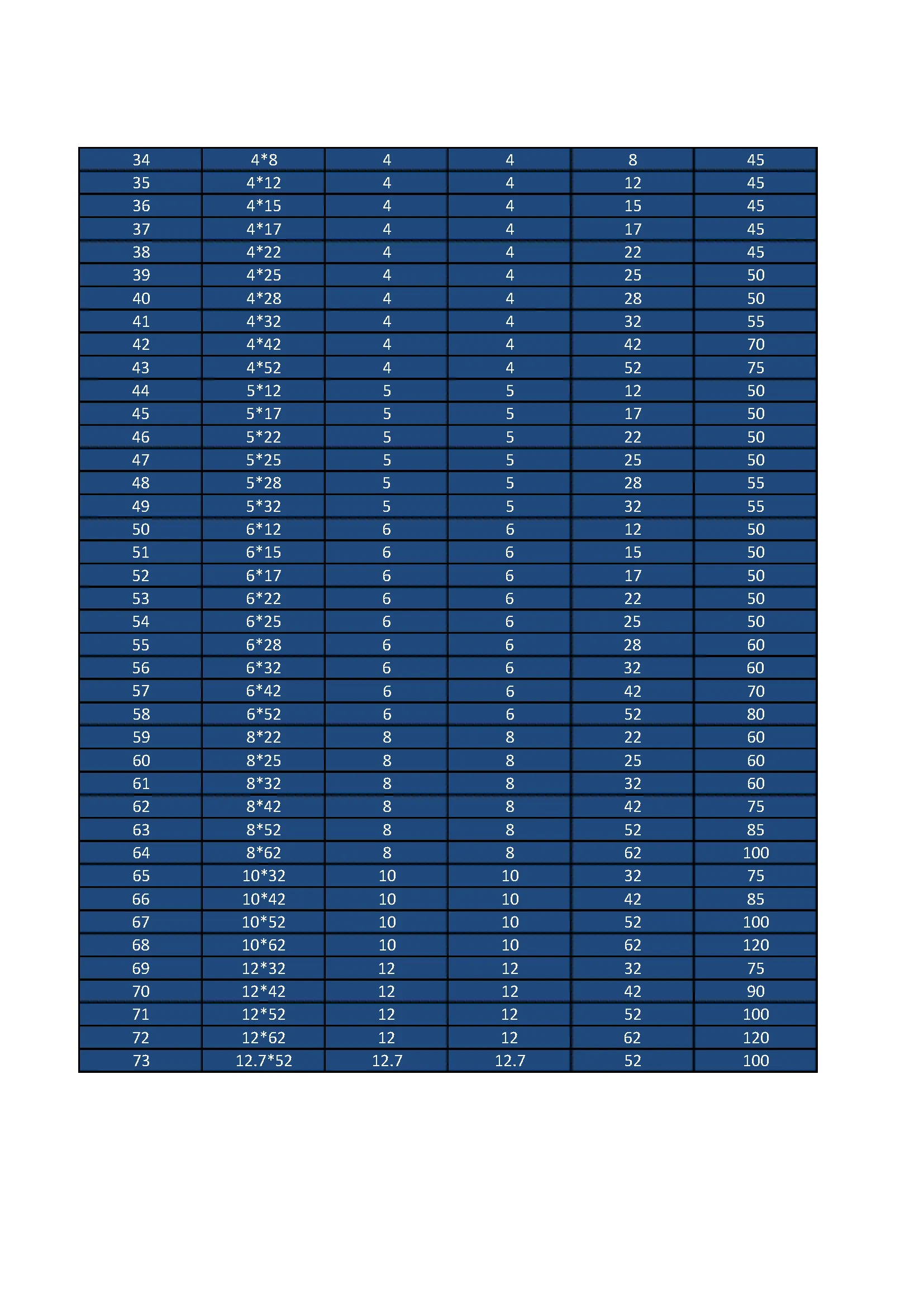

single flute end mill catalogue

The ONMY TOOLINGS Difference

What sets our single flute end mill apart? It’s our unique combination of:

Advanced Carbide Formulations

We use proprietary micro-grain carbide blends optimized for strength and wear resistance.

Innovative Geometries

Our patented flute designs maximize chip evacuation and minimize cutting forces.

Cutting-Edge Coatings

We apply nano-layered PVD coatings that enhance heat resistance and reduce friction.

Precision Grinding

Our multi-axis CNC grinders achieve tolerances as tight as ±0.0005 inches.

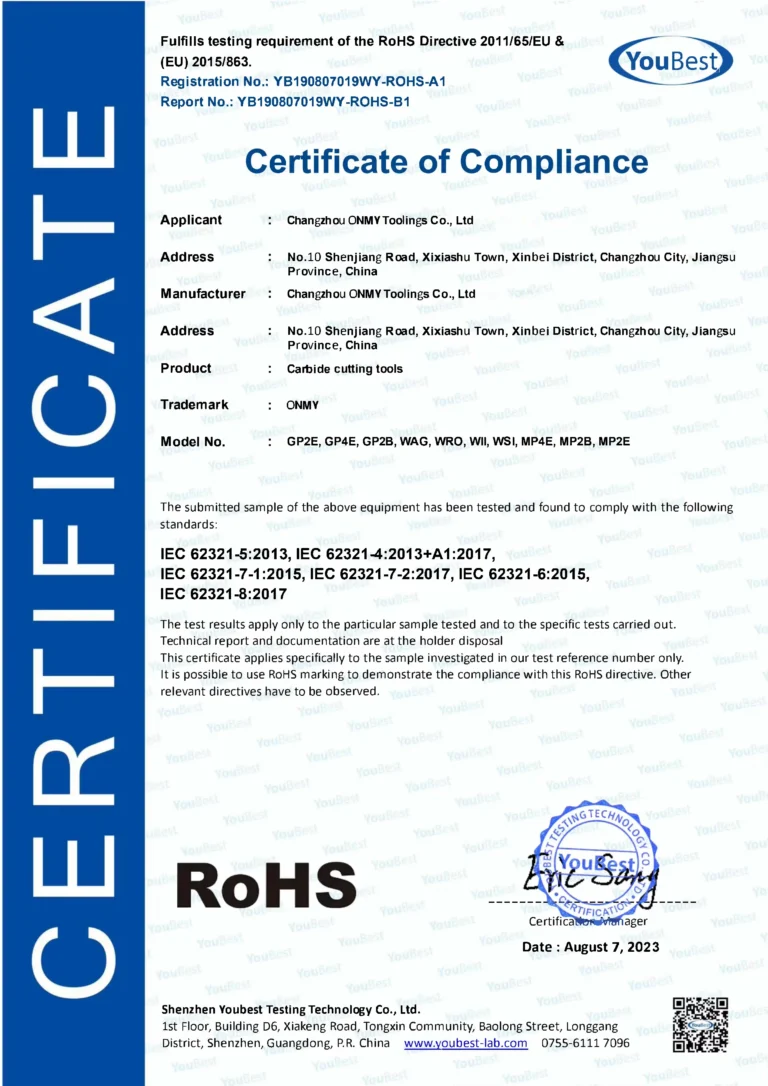

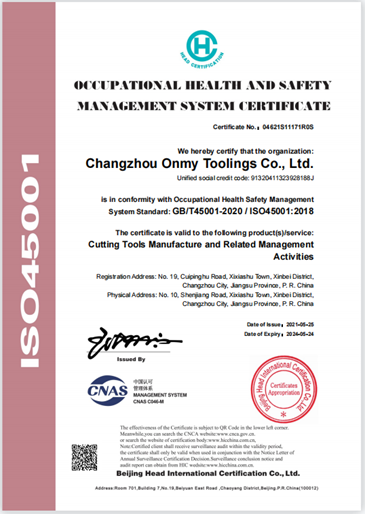

Factory Certification

These certifications aren’t just fancy badges – they’re your guarantee of consistent, top-tier quality in every tool we produce. Our quality control process includes 100% inspection of critical dimensions and advanced wear resistance testing to ensure each tool meets our exacting standards.

Our Journey to Excellence

Our story began in a small workshop with a big dream: to create the world’s finest bull nose end mills. Today, we operate a state-of-the-art 50,000 sq ft facility equipped with the latest in CNC grinding technology and advanced coating systems. But our true strength lies in our team of passionate engineers and skilled craftsmen who pour their expertise into every tool we produce.

Why settle for off-the-shelf solutions when you can have custom end mills tailored to your specific needs? Our in-house research and development team is constantly pushing the boundaries of what’s possible in machining technology. We collaborate with leading universities and industry partners to stay at the forefront of material science and cutting tool design.

Don't just take our word for it. Here's what our satisfied customers have to say:

My Happy Client!

Get Your Custom Quote Now!

P.S. Did we mention we offer bulk discounts? The more you order, the more you save!

- Unbeatable Factory-Direct Pricing: Cut out the middleman and save up to 40% compared to retail prices. Our efficient manufacturing process allows us to offer premium quality at competitive rates.

- Lightning-Fast Delivery: With our streamlined production process, we offer industry-leading turnaround times. Get your custom end mills in as little as 7 days! We maintain a large inventory of standard sizes for immediate shipment.

- Personalized Service: Our team of expert engineers is ready to help you find the perfect solution for your unique machining challenges. We offer free consultations to analyze your specific needs and recommend the ideal tool specifications.

Frequently Asked Questions

Aluminum, MDF, solid wood, plastic, and acrylic.

single flute end mills excel at high-speed machining of soft materials, prioritizing material removal rate and surface finish. Double flute end mills provide a more versatile option, suitable for a broader range of materials and offering a balance of chip removal and tool strength.