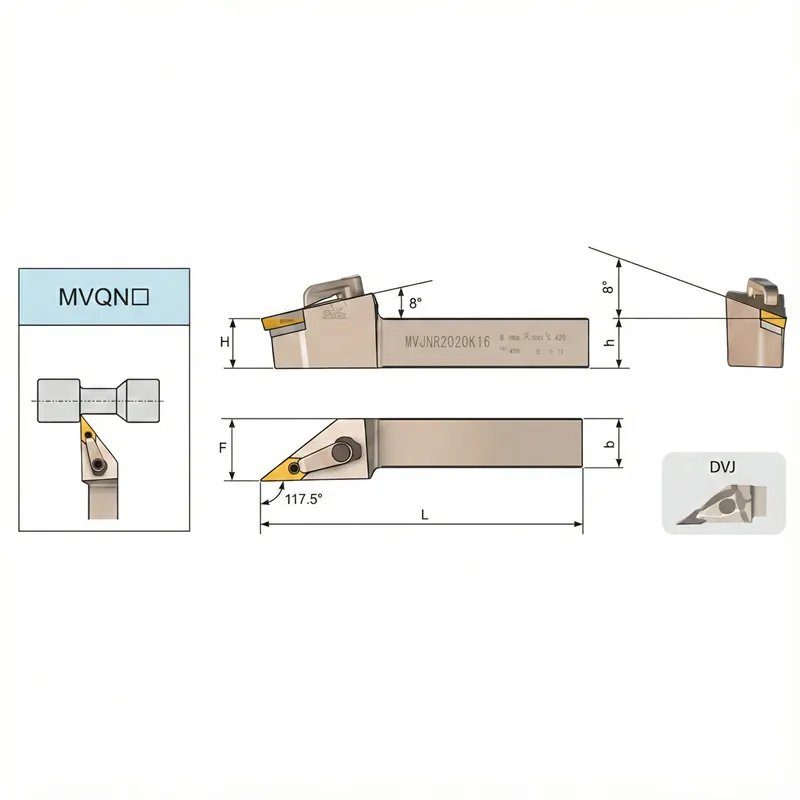

- Tool Type: External Turning Tool Holder (OD Turning)

- Model Series: MVQNR/L (Right & Left Hand)

- Entering Angle: 107.5° Entering Angle (Ideal for undercutting)

- Clamping System: M-Type Double Clamp (Pin & Top Clamp)

- Insert Compatibility: VNMG, VNMA, VNMM (35° Diamond Inserts)

-

Key Application: Deep profiling, back-turning, and undercutting operations.

Contact our sales team to discover all of your pricing options.

Overview

The MVQNR/L series is the ultimate solution for complex CNC profiling. Unlike standard holders, the MVQNR TOOL HOLDER features a specific 107.5° entering angle (often cited as -17.5° lead angle). This geometry provides the necessary clearance to perform “back turning” and undercutting (cutting away from the chuck), allowing machinists to trace intricate contours and reliefs that 93° tools cannot reach.

Optimized for VNMG Inserts

Designed to seat the slender VNMG insert (35° Diamond), this holder combines maximum accessibility with fine finishing capabilities. It is widely used in industries requiring high-precision contouring on shafts and aerospace components. Whether you use the compact MVQNR 2020K16 or the robust MVQNR 2525 version, this tool ensures precise copy turning.

Rigid M-Type Stability

Profiling in multiple directions creates varying radial forces. To counteract this, the MVQNR utilizes the M-Type Double Clamping System. The lock pin and top clamp securely hold the narrow VNMG insert, preventing displacement during the push-and-pull motions typical of profiling cycles.

ISO Code Naming Rules

Here is the breakdown of the MVQNR code, highlighting its specialized “Q” geometry:

| Position | Code | Parameter | Description & Technical Advantage |

| 1st | M | Clamping Method |

Multi-lock (Double Clamp): Uses pin & top clamp. • Benefit: Critical for holding the 35° insert stable during multi-directional cuts. |

| 2nd | V | Insert Shape |

35° Diamond: Fits VNMG inserts. • Benefit: The best insert shape for penetrating tight corners and fine finishing. |

| 3rd | Q | Holder Style |

107.5° Entering Angle: (-17.5° Lead Angle). • Benefit: The defining feature. Allows for undercutting and back-turning clearance. |

| 4th | N | Clearance Angle |

Negative (0°): Insert sits perpendicular. • Benefit: Provides 4 usable cutting edges (Double-sided), improving economy. |

| 5th | R/L | Hand of Tool |

Right (R) / Left (L): Direction of cut. • Benefit: Select based on profiling direction and turret setup. |

FAQ

Q1: What is the difference between MVQNR and MVJNR?

A: It comes down to the angle and application. MVJNR has a 93° angle, which is great for turning and facing square shoulders. MVQNR has a 107.5° angle, which cannot cut a square shoulder but is essential for undercutting (cutting reliefs) and back-turning where the tool needs extra clearance.

Q2: Why use a VNMG insert for profiling?

A: The VNMG insert has a narrow 35° point angle. This allows the tool to enter very tight grooves and follow steep angles that wider inserts (like CNMG or TNMG) would interfere with.

Q3: Can I use MVQNR 2525 for roughing?

A: We recommend limiting MVQNR 2525 to light roughing or finishing. The 35° insert tip is fragile compared to an 80° CNMG insert. Heavy roughing with a V-style insert can lead to tip breakage.

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options