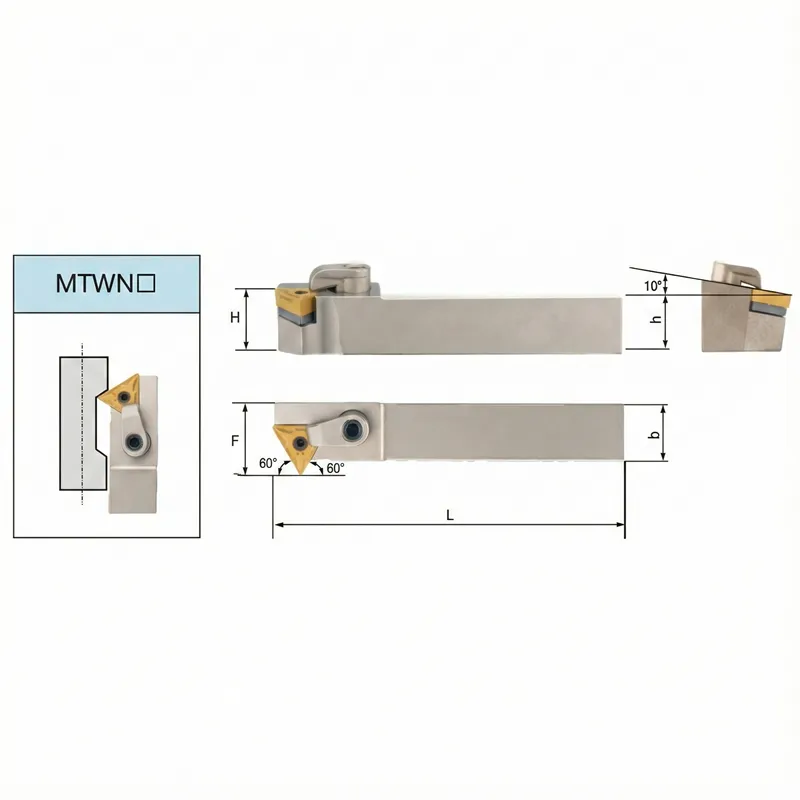

MTWNR/L External Turning Tool Holder

- Tool Type: External Turning Tool Holder (OD Turning)

- Model Series: MTWNR/L (Right & Left Hand)

- Entering Angle: 60° Entering Angle (30° Lead Angle)

- Clamping System: M-Type Double Clamp (Pin & Top Clamp)

- Insert Compatibility: TNMG, TNMA, TNMM (Negative Triangle Inserts)

-

Key Application: Heavy roughing, chamfering, and facing with specific clearance requirements.

Contact our sales team to discover all of your pricing options.

MTWNR/L 60° Turning Tool Holder for Heavy Duty Machining

Overview

The MTWNR/L series is a robust external turning tool holder designed for efficiency in roughing and chamfering applications. Distinguished by its 60° entering angle, this directional holder (available in Right and Left hand) is an excellent alternative to neutral holders when a side-cutting action is preferred. It directs cutting forces axially, making it stable for heavy cuts on rigid workpieces.

Optimized for TNMG Inserts

This holder is engineered to securely seat TNMG inserts (Triangle). By utilizing the 60° geometry of the holder, it maximizes the utility of the triangular insert’s cutting edges. The 60° approach angle allows for substantial chip thinning, enabling higher feed rates compared to standard 90° tools, while protecting the insert corner.

Rigid M-Type Stability

Like other high-performance roughing tools, the MTWNR/L features the M-Type Double Clamping System. The combination of a locking pin and a heavy-duty top clamp ensures the insert is pulled tightly into the pocket. This rigidity is essential when performing heavy roughing or interrupted cuts on steel and cast iron.

ISO Code Naming Rules

Here is the technical breakdown of the MTWNR/L code, focusing on the specific “W” style geometry:

| Position | Code | Parameter | Description & Technical Advantage |

| 1st | M | Clamping Method |

Multi-lock (Double Clamp): Uses pin & top clamp. • Benefit: Provides maximum holding power for heavy roughing. |

| 2nd | T | Insert Shape |

Triangle (60°): Fits TNMG/TNMA inserts. • Benefit: Economical 6-edge insert solution for turning. |

| 3rd | W | Holder Style |

60° Entering Angle: (30° Lead Angle). • Benefit: Distributes cutting forces over a wider edge section, allowing higher feed rates and chamfering. |

| 4th | N | Clearance Angle |

Negative (0°): Insert sits perpendicular. • Benefit: Strongest cutting edge configuration for tough materials. |

| 5th | R/L | Hand of Tool |

Right (R) / Left (L): Direction of cut.

|

FAQs

Q1: What is the difference between MTWNR and MTENN?

A: Both have a 60° entering angle and use TNMG inserts. The key difference is the hand. MTENN is Neutral (symmetric) and sits in the center. MTWNR is a Right-hand side tool (MTWNL is Left-hand). MTWNR is often preferred when you need a directed 60° cut rather than a neutral setup.

Q2: What is the benefit of the 60° entering angle on MTWNR?

A: The 60° angle (30° lead) thins the chip thickness effectively. This allows you to increase the feed rate (mm/rev) without increasing the cutting load on the insert nose, making it highly efficient for removing large amounts of material quickly.

Q3: Can I use this tool for Chamfering?

A: Yes, the geometry is perfect for creating large chamfers or bevels on the workpiece edge.

Specifications

| MODEL | SIZE(MM) | INSERT | SHIM | CENTER PIN | WRENCH | PLATEN | DOUBLE SCREW | WRENCH | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LEFT | RIGHT | h | b | H | F | L | |||||||

| MTWNL1616H16 | MTWNR1616H16 | 16 | 16 | 16 | 20 | 100 | TN□□1604□□ | MT1603 | CTM513 | L2 | HL1813 | ML0625 | L3 |

| MTWNL2020K16 | MTWNR2020K16 | 20 | 20 | 20 | 25 | 125 | TN□□1604□□ | ||||||

| MTWNL2525M16 | MTWNR2525M16 | 25 | 25 | 25 | 32 | 150 | TN□□1604□□ |

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options