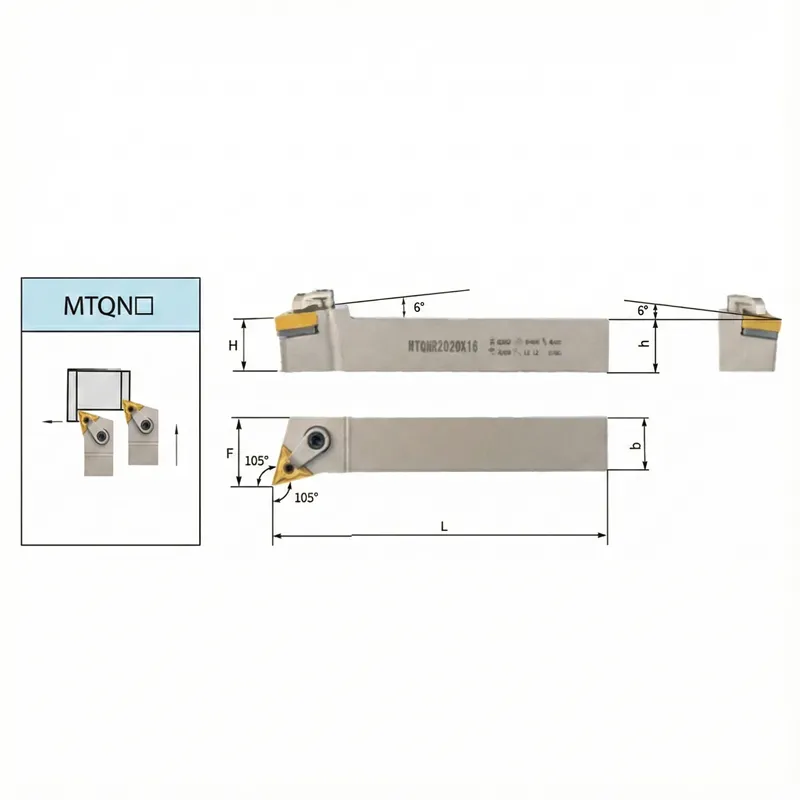

- Tool Type: External Turning Tool Holder (OD Turning)

- Model Series: MTQNR/L (Right & Left Hand)

- Entering Angle: 105° Entering Angle (Ideal for undercutting)

- Clamping System: M-Type Double Clamp (Pin & Top Clamp)

- Insert Compatibility: TNMG, TNMA, TNMM (Negative Triangle Inserts)

-

Key Application: Back turning, relieving, and profiling contours.

Contact our sales team to discover all of your pricing options.

MTQNR Tool Holder with 105° Angle for Undercutting

The MTQNR/L series is a specialized external turning tool holder designed to solve complex geometry challenges. Featuring a specific 105° entering angle (15° lead angle clearance), this tool provides the necessary clearance to perform “back turning” and undercutting operations that standard 93° tools cannot reach.

Optimized for Profiling with TNMG Inserts

This holder is engineered to seat TNMG inserts (Triangle). The combination of the economical 6-edge insert and the 105° geometry makes it perfect for copy turning (profiling) applications where the tool needs to navigate descending contours or create relief grooves without interference from the tool body.

Rigid M-Type Stability

Profiling and undercutting can generate unstable cutting forces. The MTQNR tool holder utilizes the robust M-Type Double Clamping System. By securing the insert with both a lock pin and a top clamp, it ensures the insert remains rigid during multi-directional cutting, providing excellent surface finish and dimensional accuracy.

ISO Code Naming Rules

Here is the breakdown of the MTQNR/L code, specifically highlighting the angle parameter:

| Position | Code | Parameter | Description & Technical Advantage |

| 1st | M | Clamping Method |

Multi-lock (Double Clamp): Uses pin & top clamp. • Benefit: Maximum stability for multidirectional profiling forces. |

| 2nd | T | Insert Shape |

Triangle (60°): Fits TNMG/TNMA inserts. • Benefit: Provides excellent access for profiling with 6 economical cutting edges. |

| 3rd | Q | Holder Style |

105° Entering Angle: • Benefit: The defining feature. Allows for undercutting and relieving operations with 15° clearance. |

| 4th | N | Clearance Angle |

Negative (0°): Insert sits perpendicular. • Benefit: Utilizing negative inserts ensures high edge strength. |

| 5th | R/L | Hand of Tool |

Right (R) / Left (L): Direction of cut. • Benefit: Choose based on whether you are turning towards or away from the chuck. |

FAQ

Q1: What is the main use of the 105° entering angle on the MTQNR?

A: The 105° angle allows the tool to cut “backwards” or undercut surfaces (creating a relief) without the back of the tool holder hitting the workpiece. It is essential for specific profiling shapes.

Q2: Does the MTQNR use standard TNMG inserts?

A: Yes. Despite the special 105° angle of the holder, it uses standard ISO TNMG inserts. This means you don’t need to buy special inserts just for this holder; you can use the same ones as your MTJNR or MTENN holders.

Q3: Can I use this for heavy roughing?

A: It is possible, but usually, an MTJNR (93°) or MSSNR (45°) is better for heavy roughing due to better force distribution. The MTQNR is best reserved for profiling and finishing complex shapes where its geometry is required.

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options