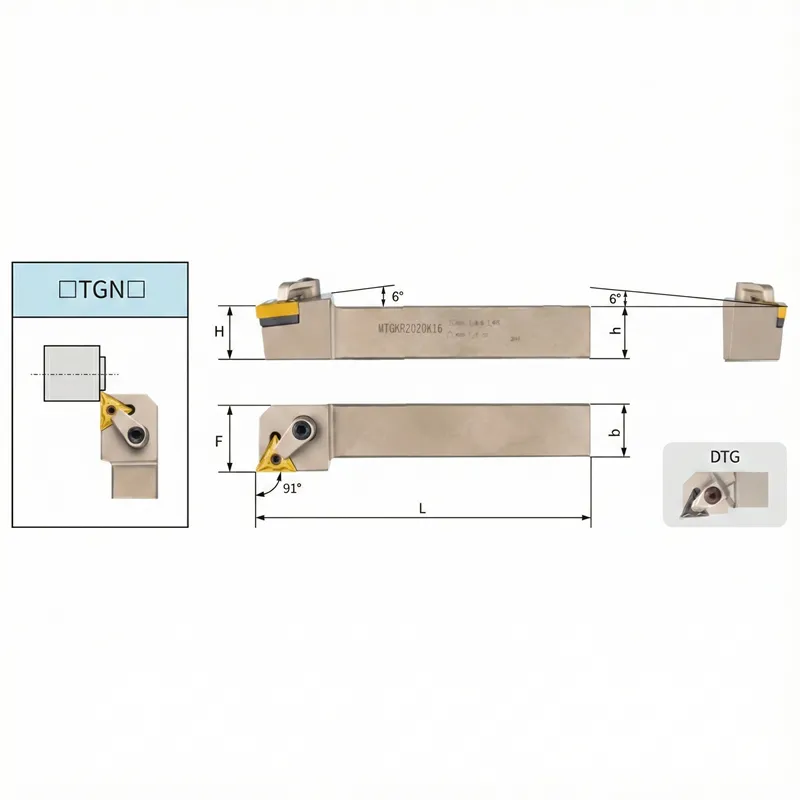

MTGNR/L Series: Heavy-Duty M-Type Multi-Lock OD Turning Tool Holder for TNMG Inserts (91° Approach Angle)

The MTGNR/L is a versatile and rigid OD turning tool holder designed for high-efficiency CNC machining. Built to ISO standards, this TNMG tool holder features an M-Type Multi-Lock clamping system that combines a top clamp with a locking pin for ultimate insert stability. Its 91° approach angle provides the necessary clearance for longitudinal turning and facing, making it an essential tool for roughing and semi-finishing operations in steel, stainless, and cast iron.

Contact our sales team to discover all of your pricing options.

Technical Analysis: The MTGNR/L Configuration

The MTGNR/L is defined by its geometry, optimized for stability and cost-efficiency. As a dedicated TNMG tool holder, it leverages the strength of negative triangular inserts.

| Position | Code | Definition | Technical Advantage |

| 1st | M | Clamping System | Multi-Lock: The gold standard for stability. Uses both a lever-pin and a top clamp to ensure the insert never moves, even under heavy interrupted cuts. |

| 2nd | T | Insert Shape | Triangular (60°): Uses TNMG inserts with 6 usable cutting edges, significantly lowering your cost-per-part. |

| 3rd | G | Holder Style | 91° Approach Angle: Optimized for longitudinal turning and facing with $1^\circ$ of clearance to prevent side-wall friction. |

| 4th | N | Clearance Angle | 0° (Negative): Negative rake inserts provide a stronger edge cross-section, ideal for heavy OD turning tool holder applications. |

| 5th | R/L | Hand of Tool | Right (R) or Left (L): Available in both hands to suit any CNC lathe turret configuration. |

Key Performance Benefits

- Superior Clamping Force: The M-Type design is specifically built to handle high-torque operations, reducing harmonics and chatter that can lead to premature insert failure.

- Precision 91° Geometry: The 1° lead angle ensures that while the tool turns a 90° shoulder, the side cutting edge does not rub against the workpiece, resulting in a cleaner surface finish and lower heat generation.

- Versatile OD Turning: Whether you are performing straight turning or facing toward the center, the MTGNR/L remains stable, making it a “workhorse” for general engineering.

-

High Material Removal Rates (MRR): Designed to withstand the forces of high-feed roughing, this TNMG tool holder excels in bulk material removal.

Frequently Asked Questions (FAQs)

Q: What is the difference between MTGNR and MTFNR holders?

A: Both feature a 91° approach angle. However, the G-style (MTGNR) is typically designed for a specific orientation that makes it slightly more versatile for both longitudinal turning and facing in certain turret setups compared to the F-style.

Q: Why should I use an OD turning tool holder with an M-Type clamp instead of a P-Type?

A: P-Type holders use only a hole-pulling pin. While effective, the M-Type (Multi-Lock) adds a top clamp. This extra downward pressure is critical for heavy roughing or when machining materials that cause high vibration, as it keeps the insert perfectly seated.

Q: Which inserts fit this TNMG tool holder?

A: It is compatible with all standard ISO TNMG inserts (e.g., TNMG 160408). Ensure the size code of the holder (e.g., 16, 22) matches the first two digits of your TNMG insert size.

Q: Can I use this for finishing cuts?

A: Yes. While the MTGNR/L is excellent for roughing due to its rigidity, it can be used for finishing when paired with a finishing-geometry TNMG insert (like a -PF or -SF chipbreaker) and a smaller nose radius.

| MODEL | SIZE(MM) | INSERT | SHIM | CENTER PIN | WRENCH | PLATEN | DOUBLE SCREW | WRENCH | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LEFT | RIGHT | h | b | H | F | L | |||||||

| MTGNL1616H16 | MTGNR1616H16 | 16 | 16 | 16 | 20 | 100 | TN□□1604□□ | MT1603 | CTM513 | L2 | HL1813 | ML0625 | L3 |

| MTGNL2020K16 | MTGNR2020K16 | 20 | 20 | 20 | 25 | 125 | TN□□1604□□ | ||||||

| MTGNL2525M16 | MTGNR2525M16 | 25 | 25 | 25 | 32 | 150 | TN□□1604□□ | ||||||

| MTGNL3232P16 | MTGNR3232P16 | 32 | 32 | 32 | 40 | 170 | TN□□1604□□ |

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options