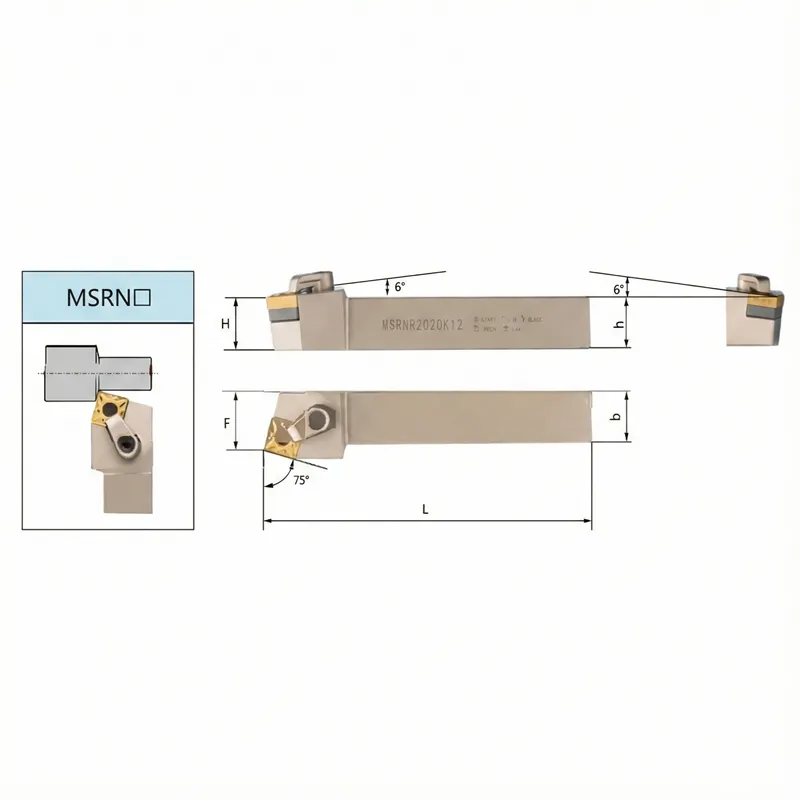

Engineered for aggressive material removal, the MSRNR/L Turning Tool Holder offers a specialized 75-degree lead angle that balances edge strength with chip thinning efficiency. As a premium dnmg tool holder, it provides the structural integrity needed for high-torque applications. This dnmg holder is a critical component for shops requiring a stable dnmg insert holder to maximize the performance of DNMG, DNMA, and DNMM inserts.

Contact our sales team to discover all of your pricing options.

High-Removal MSRNR/L 75° Tooling for Industrial Lathes

The MSRNR/L tool holder is built for the most demanding CNC turning tool holder types. By utilizing a 75-degree approach angle, this tool directs cutting forces more axially into the spindle, reducing the risk of workpiece deflection. While many operators look for a dnmg neutral tool holder for profiling, the MSRNR/L is the preferred choice for powerful longitudinal cuts where stability is the absolute priority in a lathe turning tool holder.

Strategic Versatility with DN-Series Inserts

This dnmg insert holder is precision-machined to ensure a high-tolerance fit, preventing the vibration that often leads to carbide failure. It is fully compatible with:

-

DNMG Inserts: Perfect for multi-purpose turning on steel and stainless steel.

-

DNMA Inserts: The ideal match for cast iron processing where flat-base stability is required in a dnmg holder.

-

DNMM Inserts: Reinforced geometries that excel in interrupted cutting and heavy-duty indexable turning tool holders applications.

Advanced M-Type Clamping for Superior Grip

The MSRNR/L utilizes a sophisticated M-type double-clamping system. By pulling the insert into the seat with both a top clamp and a rigid center pin, this tool holder for turning ensures the insert cannot lift during high-feed cycles. This locking mechanism is significantly more secure than a standard dnmg tool holder with a single-point screw, allowing for deeper cuts and faster cycle times.

Specifications Table

| Feature | Details |

| Model Code | MSRNR (Right Hand) / MSRNL (Left Hand) |

| Approach Angle | 75° (Optimized for Axial Force Distribution) |

| Clamping Type | M-Type Multi-Lock (Double Clamp) |

| Compatible Inserts | DNMG, DNMA, DNMM (1504 / 1506 / 432 Series) |

| Primary Category | Indexable Turning Tool Holders |

| Body Treatment | Anti-Vibration Hardened Alloy Steel |

FAQ (Professional Support)

Q: How does the MSRNR/L 75° angle improve productivity?

A: Unlike a 95° dnmg tool holder, the 75° angle of the MSRNR/L allows the load to be spread over a longer portion of the cutting edge. This promotes chip thinning and heat dissipation, letting you push higher feed rates without breaking your DNMG inserts.

Q: Can the MSRNR/L replace a dnmg neutral tool holder for general tasks?

A: The MSRNR/L is a directional (Handed) tool, whereas a dnmg neutral tool holder is centered. Use the MSRNR/L for heavy, one-directional roughing where maximum rigidity is needed; use a neutral holder for symmetrical profiling or chamfering.

Q: Is this dnmg insert holder compatible with different brands of inserts?

A: Yes. As long as the inserts follow the standard ISO/ANSI DNMG geometry (55° diamond), this dnmg holder will provide a perfect fit and high clamping security.

Need a consultation? Contact us!

Contact our sales team to discover all of your pricing options