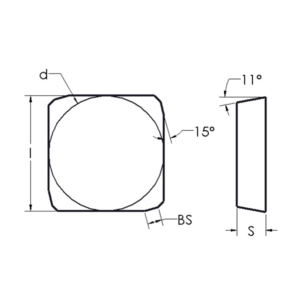

SPKN insert

General purpose ISO face milling insert

- Used with wedge clamp style milling cutters

- Fully interchangeable with other SPK/SPKN inserts

- Also fits milling cutters using insert types SMA, SMK, SPCN, SPEN and SPMN

- Reinforced cutting edge for medium to roughing applications

- Four cutting edges for economy

SPKN Insert Specification Guide

- S: Square shape, providing four cutting edges.

- P: Positive rake angle, which helps reduce cutting forces.

- K: Usually indicates a specific feature of the cutting edge or tolerance class.

- N: Often denotes the absence of a chip breaker or a particular nose radius.

Key features of SPKN insert

- Versatile, suitable for face milling and shoulder milling operations.

- Good balance between edge strength and sharpness.

- Effective for both roughing and finishing operations.

- Typically used for machining materials like steel, stainless steel, and cast iron.

- The positive rake angle can be beneficial for less rigid setups or challenging materials.

- Four cutting edges per insert, offering cost-effectiveness and extended use.

SPKN inserts are valued for their versatility and ability to perform well across various cutting conditions and materials. They’re designed to offer a good compromise between durability and cutting efficiency in milling applications.

Applications

- Face Milling: Ideal for creating flat surfaces on large workpieces.

- Shoulder Milling: Excellent for producing 90-degree walls and corners.

- General-Purpose Milling: Suitable for a wide range of milling operations.

- Steel Machining: Performs well on various grades of carbon and alloy steels.

- Stainless Steel Work: Effective for cutting different types of stainless steel.

- Cast Iron Operations: Suitable for machining gray and ductile cast iron.

- Roughing: Capable of handling heavy material removal in roughing passes.

- Finishing: Sharp edges allow for high-quality surface finishes.

- Medium-Duty Cutting: Optimal for moderate cutting depths and feed rates.

- CNC Machining: Compatible with CNC milling machines for precision work.

Why Choose Our Inserts?

Versatility

Excels in face and shoulder milling operations.

Cost-effective

Four cutting edges per insert for extended use.

Balanced performance

Suitable for both roughing and finishing

Reduced cutting forces

Positive rake angle for smoother machining.

Frequently Asked Questions

What does SPKN stand for?

S-Square shape, P-Positive rake, K-Specific edge feature, N-Typically no chip breaker.

What materials can SPKN inserts machine?

Primarily steel, stainless steel, and cast iron.

What are the main applications for SPKN inserts?

Face milling and shoulder milling are primary applications.

How many cutting edges does an SPKN insert have?

Four cutting edges.

Are SPKN inserts suitable for both roughing and finishing?

Yes, they can handle both operations effectively.

How does the positive rake angle benefit machining?

It reduces cutting forces, improving efficiency and surface finish.

Our Production Capability